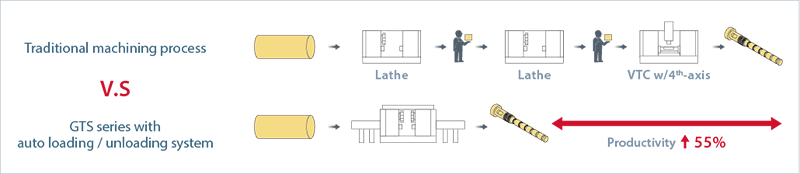

EXTREME MACHINING PERFORMANCE

2nd Spindle Catches Parts Automatically

2nd Spindle Catches Parts Automatically

2nd spindle catches parts from 1st spindle and automatically machining rear side to avoid the error of movement manually by the operator.

Twin Spindles Simultaneous Cutting

Twin Spindles Simultaneous Cutting

By clamping two ends of the long bar on each spindle and rotate synchronous to avoid the run out of rotating by single side clamping.

Front / Rear Side Synchronous Cutting

Front / Rear Side Synchronous Cutting

The 1st and 2nd spindle synchronous cutting makes GTS series functional as two multi-tasking machines.

ACCESSORIES & APPLICATIONS

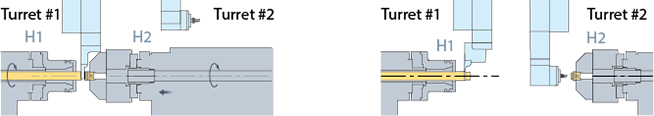

Small Parts

Small Parts

With optional bar feeder

H1 Cut-off

Synchronization cut-off

H2 Workpiece Support

Spindle stop → H2 advance with chuck open → Chuck close → Synchronization cut-off → H2 retract after cut-off

H1 Load Bar

Spindle stop → Collect chuck open → Load Bar → Collect chuck close → Spindle run → O.D. and Thread machining

H2 Turn / Mill Operation

Turning / drilling → Milling → Eject to parts catcher

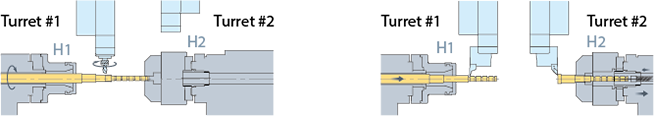

Long Parts

Long Parts

With optional bar feeder

H1 Drilling

C-axis brake → Drilling → Cut-off workpiece

H2 Workpiece Support

Chuck hold workpiece

H1 Load Bar

Collect chuck open → Load Bar → Collect chuck close → O.D. and Thread machining

H2 Turn / Mill Operation

End face and O.D. machining → Finished

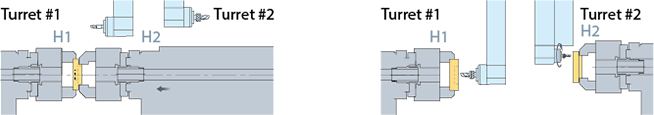

Casting /

Casting / Forge Parts

H1 Workpiece Support

Workpiece finished in H1 → Spindle stop / chuck open → Load new workpiece / chuck close

H2 Workpiece Support

Spindle stop → H2 advance with chuck open → H2 retract after cut-off

H1 Turn operation

Synchronization → O.D. machining → Bore machining

H2 Turn / Drill Operation

END face and O.D. machining → Drilling Finished