HIGH SPEED CONTROL TECHNOLOGY

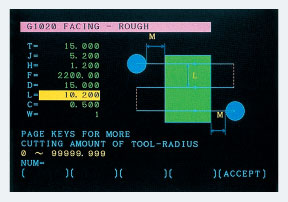

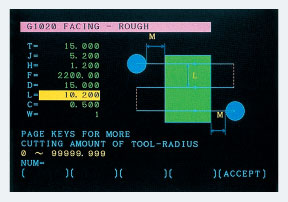

MITSUBISHI 720L shown

MITSUBISHI 720L shown

Standard with 10.4" LCD monitor, graphic display, 600M memory and high speed processor. The Window XP system is also standard with extra capacity hard disk which allows to store big number of programs. Furthermore, USB port is provided.

A powerful NAVI LATHE conversational programming is provided. Even the first-time users who don't know EIA can operates easily.

FANUC 31i shown

FANUC 31i shown

User-friendly control panel allows direct operator access to most of the machine’s setup functions without the hassle of flipping through pages in the control’s screen. High-grade push buttons and toggle switches are used to ensure durability. The control panel and housing is coolant, oil, and dirt resistant.

Standard 10.4" color LCD screen, small full keypad, graphic display, 640M of program memory, and super-fast processor.

Features such as rigid tapping, multiple repetitive cycles, direct programming, custom Macro B are standard plus many more.

Standard Manual guide i conversational programming simplifies programming, and advanced canned cycles for complex machining can be carried out automatically. Even inexperienced users can make a part program easily.

ENHANCED AUTOMATIONS

Optional bar feeders save manpower and provide greater productivity by automatically feeding bar stock into the machine after each part is completed. Servo 65 bar feeding systems feed bars up to 65 mm ( 2.5" ) diameter and Servo 80 systems feed bars up to 3" ( 80 mm ).

Available standardized or custom gantry loading / unloading systems provide automatic operation for chucking operations. These flexible systems can be intergraded onto one or more machines to suit a wide range of applications.

Home

Horizontal Turning

GS-2000 Series

Overview

Construction

Spindle

Turret

Multi-Tasking

Control

Gallery

Specifications

Dealer Network

Contact / Inquiry

MITSUBISHI 720L shown

MITSUBISHI 720L shown

FANUC 31i shown

FANUC 31i shown