MAXIMUM STRENGTH CONSTRUCTION

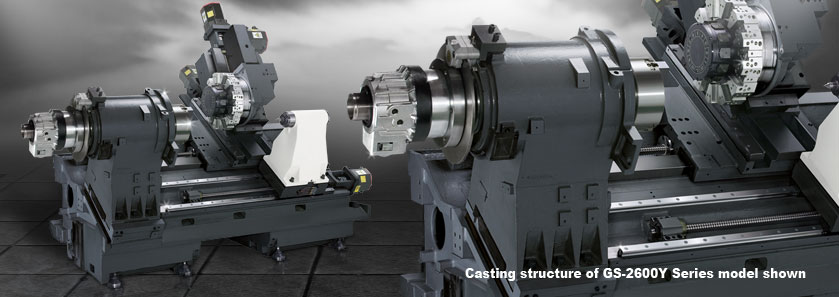

Major structural components have been combined into one solid platform. The low center of gravity 45° slant bed design provides the most rigid foundation possible for the headstock, turret, and tailstock.

By using Finite Element Methods ( FEM ), optimal reinforce ribbings are directly cast into the one-piece bed structure. Mechanical rigidity has been increased by more than 40% when compared to conventional designs. The GS-6000 series is capable of performing super heavy-duty turning and maintain long-term super high-precision accuracy. More rigidity also means extended tool life.

Built to endure years and years of rigorous high production turning, the heavily ribbed, one-piece thermally balanced bed and casting components are of FC35-Meehanite casting ( industry standard is FC25 ~ 30 ). FC35 grade cast iron is capable of withstanding much greater stress without deforming and provides maximum vibration damping, which result in a machine that will outlast and outperform the competition.

C3 class hardened and precision ground ball Z possible. Plus, pretension on all axes minimizes thermal distortion.

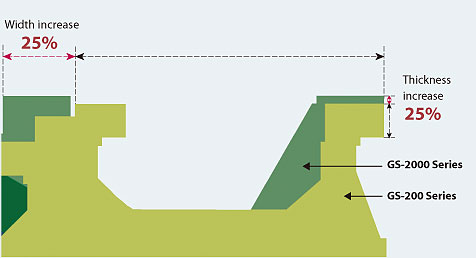

Extra wide hardened and ground box ways are directly formed onto the machine bed and saddle during the casting process. They are precision machined and widely spaced for maximum strength. The box way design also provides the rigidity needed for heavy duty and interrupted turning applications.

Slide ways are bonded with " Turcite B " to eliminate stick-slip, minimize wear and maintain long term accuracy. Rapides are 1,182 IPM ( 30 m/min ) on X & Z axes.