Advanced Spindle Technology

The built-in spindle design reduces centrifugal force effect and restrains spindle vibration, which increases the spindle life span and improves long-term machining accuracy.

The clamping mechanism uses rotary hydraulic cylinder which can firmly clamp the workpiece and provides fast response, flexible clamping force.

| Spindle motor | Clamping mechanism | |||

|---|---|---|---|---|

| Built-in | Outboard | Hydraulic cylinder |

Clutch | |

| SW-20 | H1 | H2 | --- | H1 / H2 |

| SW-32 | H1 / H2 | --- | H1 | H2 |

| SW-42 | --- | H1 / H2 | H1 | H2 |

| *H1:Main spindle H2:Sub-spindle | ||||

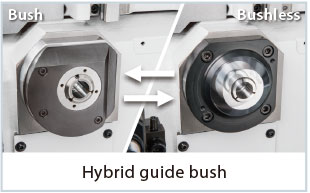

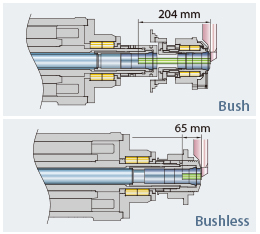

Special interface mechanical design of guide bush can be mounting or dismount base on actual situation.

It is more flexible in use and save cost on facility and space in the factory.

Bush | Suitable for long bar work-piece

Bushless | Suitable for cold working bar or high price raw material

REAR-END & C-AXIS MACHINING CAPABILITY

Sub-spindle

Sub-spindle

High precision built-in*1 sub-spindle design and movement of the sub-spindle is applied with high speed linear guide way which provides rapids up to 30 m/min.

*1 Individual models may vary, detail specification please contact us.

C-axis

C-axis

Working with the live tooling and 0.001˚ high resolution C-axis enables the machine to perform multiple tasks, such as drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations.

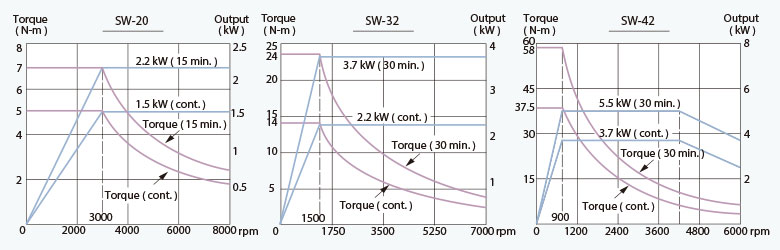

Spindle output

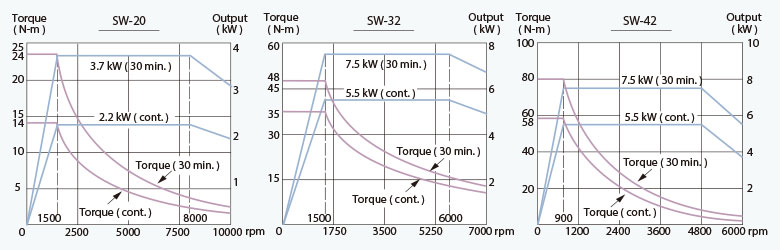

Sub-spindle output