GA-3600/W24

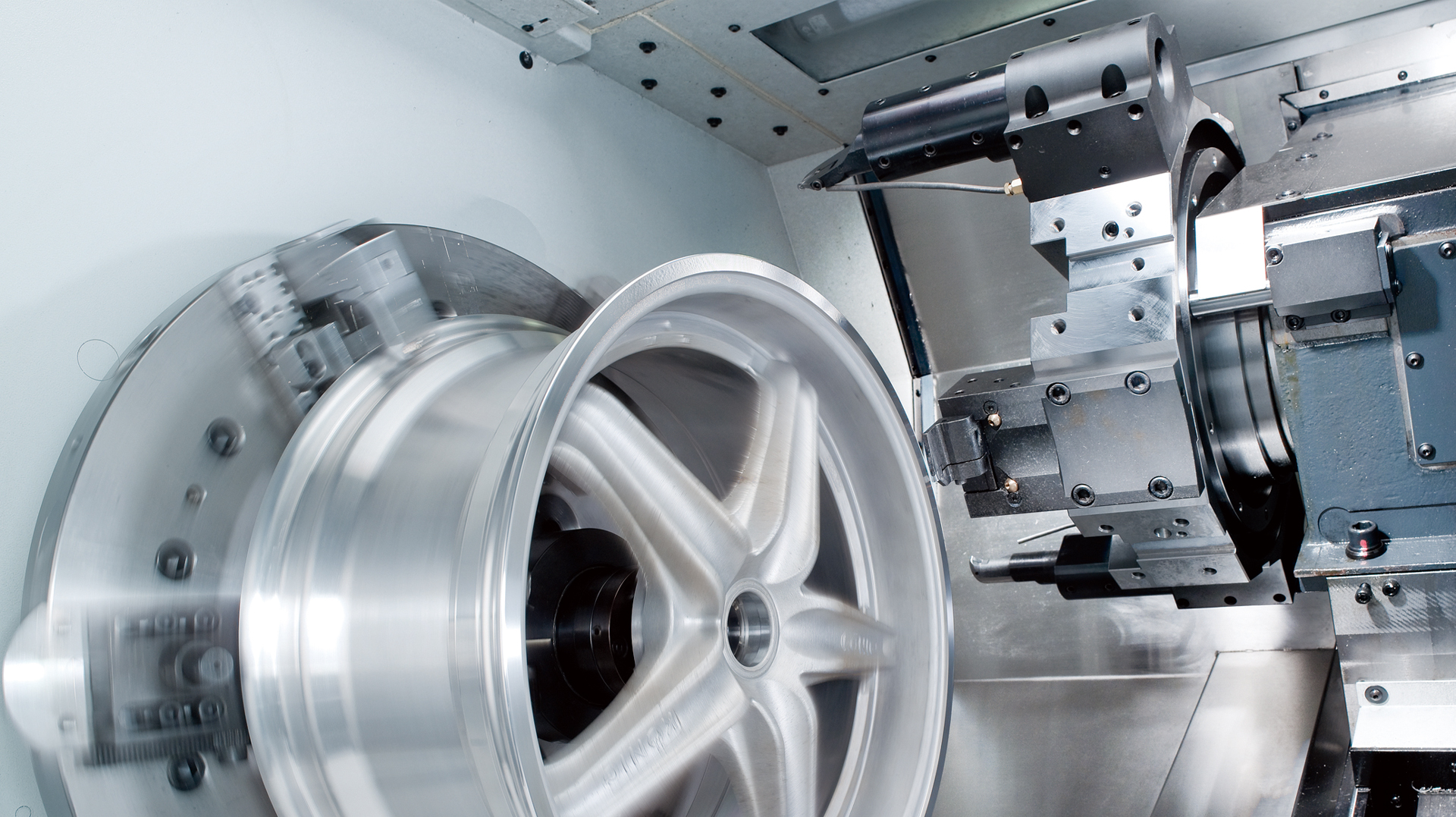

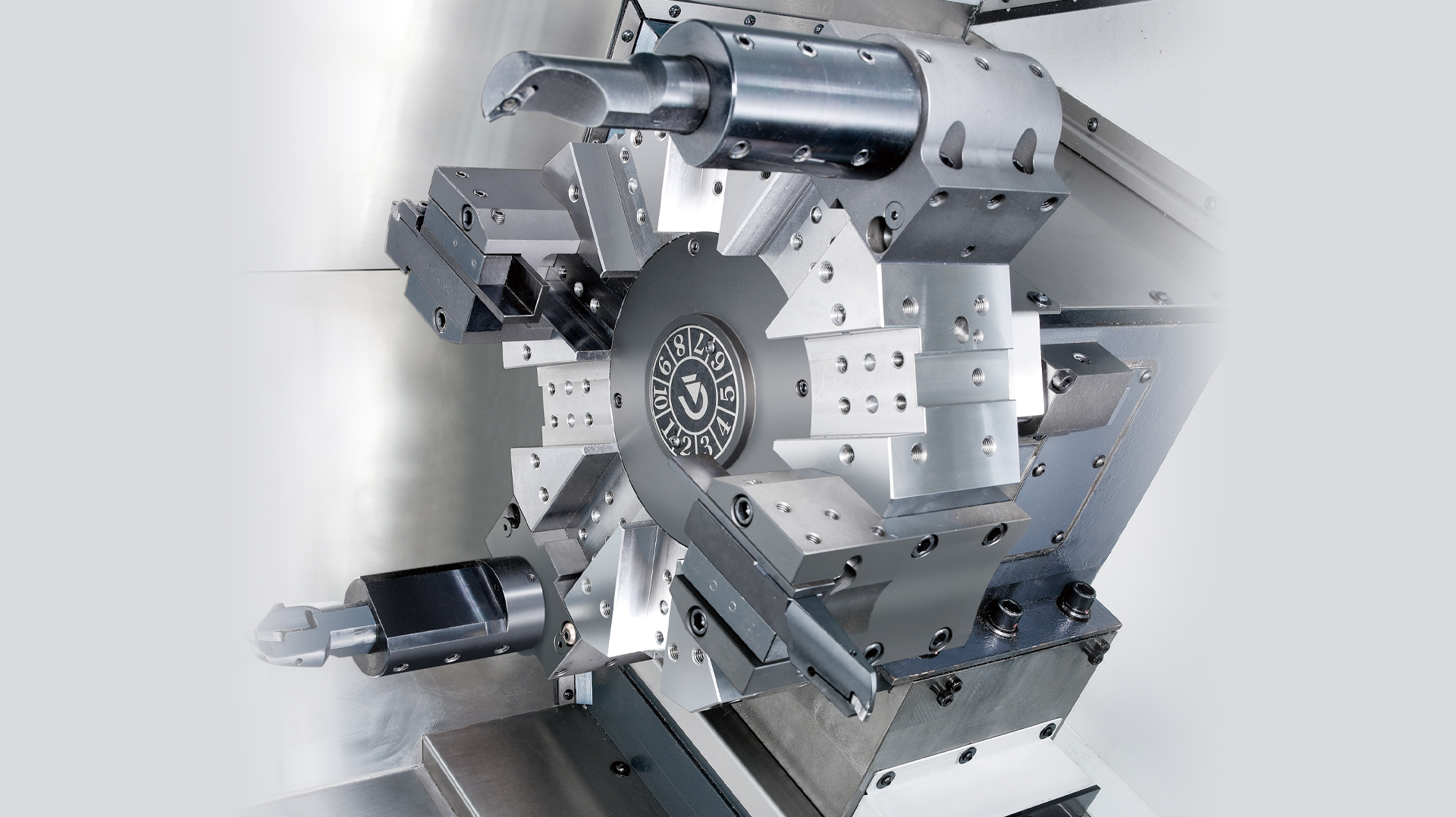

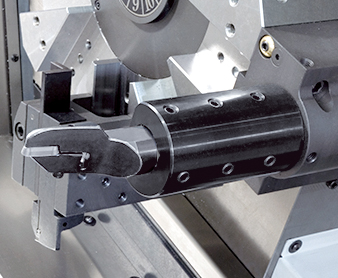

Packed with industry leading technology and top quality components, GOODWAY GA-3600/W24 combines strong constructions, customizable integrated interface for chucks, and efficient chip disposal capabilities to bring you the top choice of aluminum wheel turning center in the market. With the advantages of the load / unload feature, GA-3600/W24 series can rapidly replace cam arms and ring locators to complete 1st and 2nd operations all at once. You can combine 2 sets GA-3600/W24 machines with a machining center and robot arm to form a high performance production line that is sure to meet your turning applications for aluminum wheels of today and tomorrow.

- A chip removal solution designed for handling large volumes of chips, featuring a large chip chute, high- capacity coolant tank, and an intelligently operated chip conveyor, with an optional high-pressure coolant system.

- Maximum turning diameter up to Ø24", capable of meeting the vast majority of market demands.

- The box way design also provides the rigidity needed for heavy duty and interrupted turning applications.

- The precision hand-scraping process ensures the highest assembly accuracy and balanced load distribution.

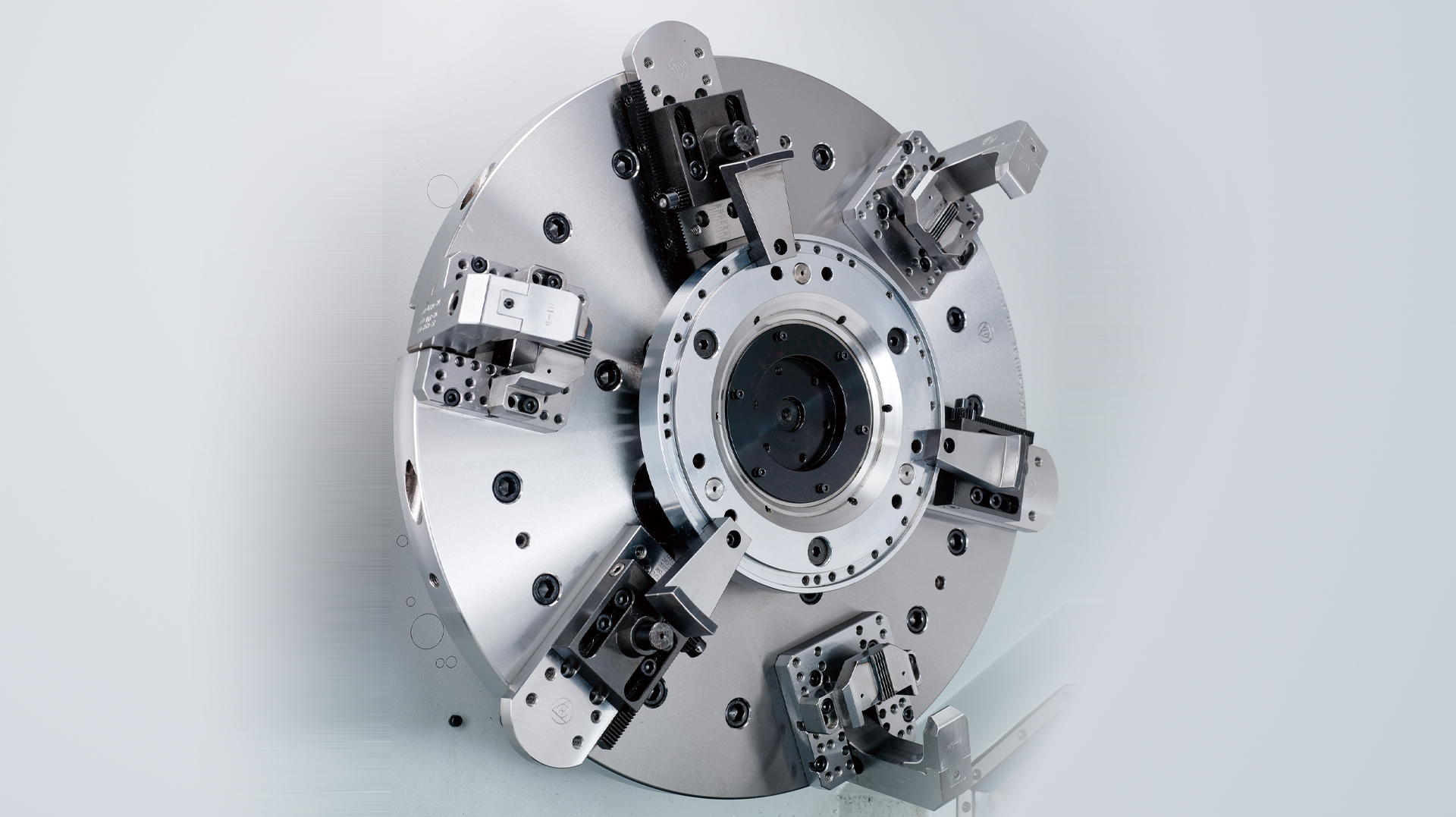

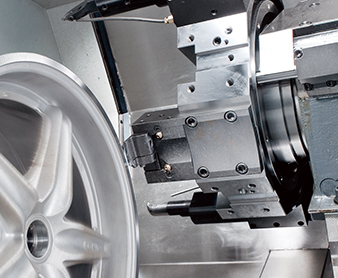

- Various jaw-type hydraulic chucks are available to suit different wheel sizes and shapes; GOODWAY also offers customized solutions.

- GOODWAY’s optimized anti-vibration tool holder ensures stable cutting performance to achieve superior surface finish requirements.

Features

High Rigidity Structure

Designed Specifically for Wheel Turning