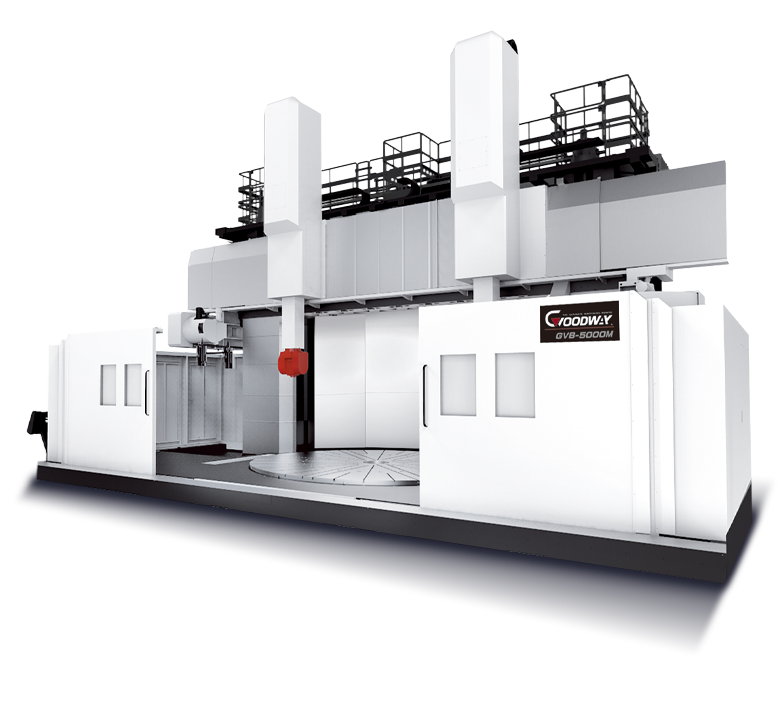

SUPER GV

With leading technologies and high quality components, the SUPER GV CNC vertical turning center combines high rigidity, heavy load capacity and super large machining range advantages to provide you with large sized, asymmetric work piece turning capabilities. The optimal reinforced structure of these series can maintain long term precision even if the table diameter is reached up to 8,000mm. Plus, with the optional dual ram or live tooling spindle and C-axis, all kinds of complex turning applications can be done easily, which can meet your needs for today and tomorrow.

- The ideal solution for machining oversized, heavy workpieces, meeting the demands of industries such as energy, shipbuilding, and aerospace.

- Maximum turning diameter can reach up to Ø 9,000 mm; maximum work-piece weight can reach up to 300,000 kg.

- Optional twin ram configuration provides greater flexibility in process planning and enhances machining efficiency.

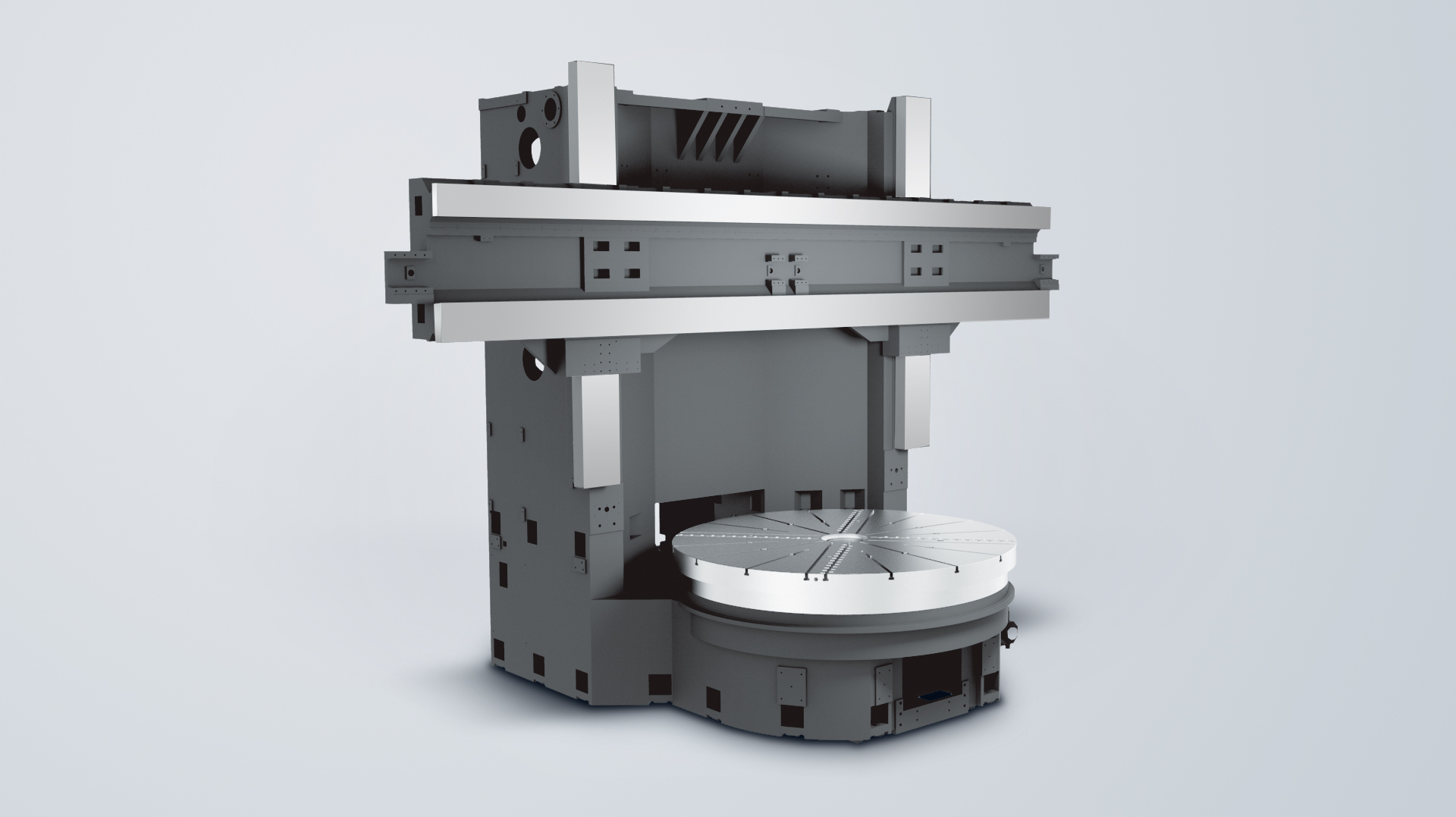

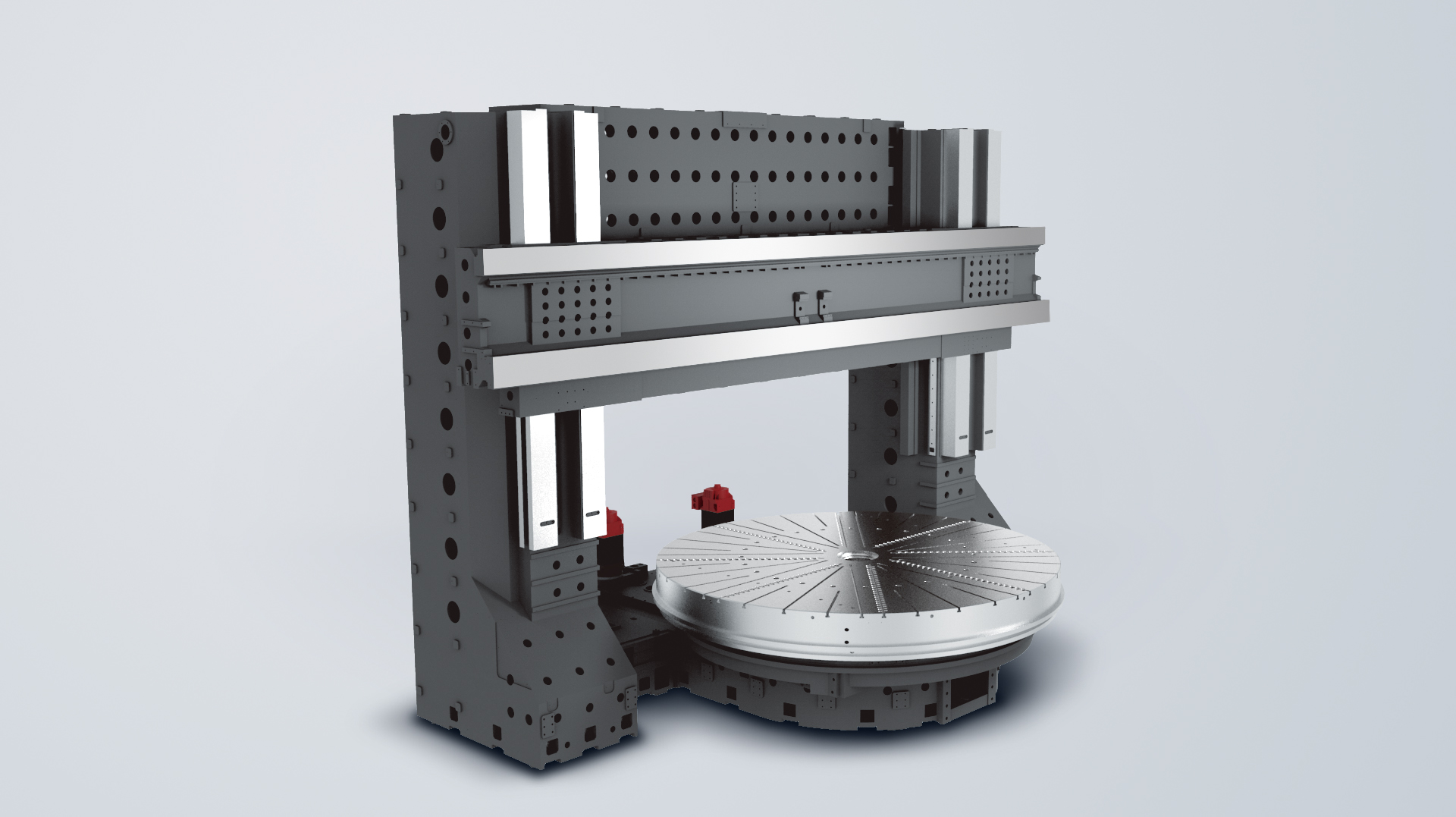

- Both X and Z axes feature oversized box ways combined with a wide-span design.

- One-piece column & structure ( GVH series ).

- W-axis four-guideway bridge type structure ( GVB series ).

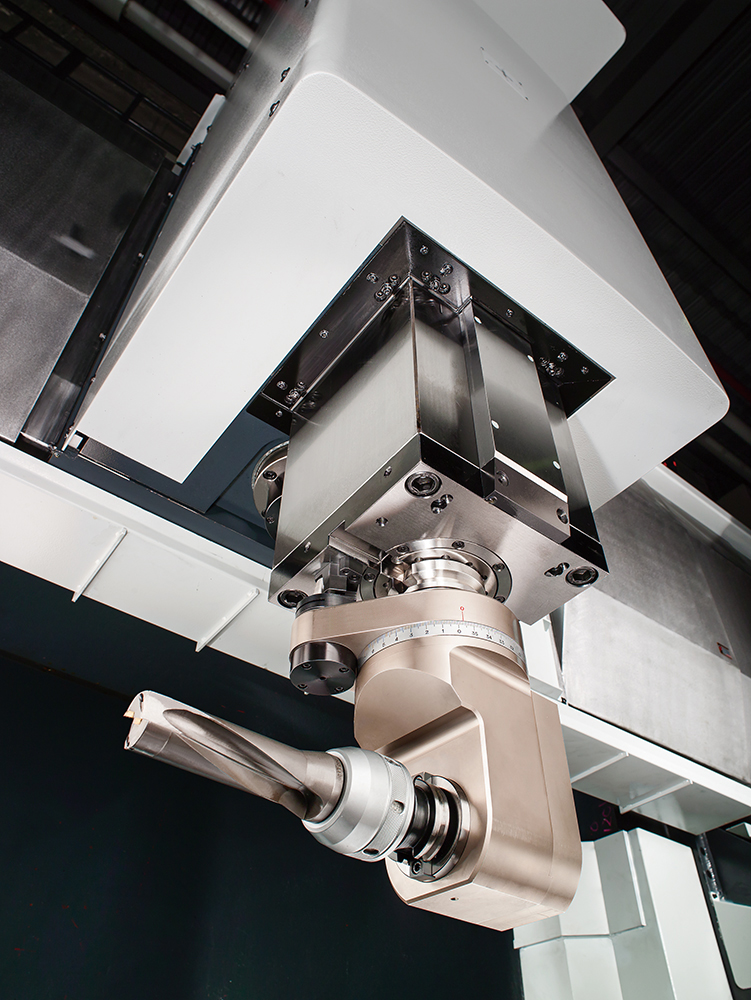

- The live tooling spindle features a 2-speed gear box design, delivering high torque output. In the GVH series, tool spindle speed reaches up to 4,000 rpm (milling function optional).

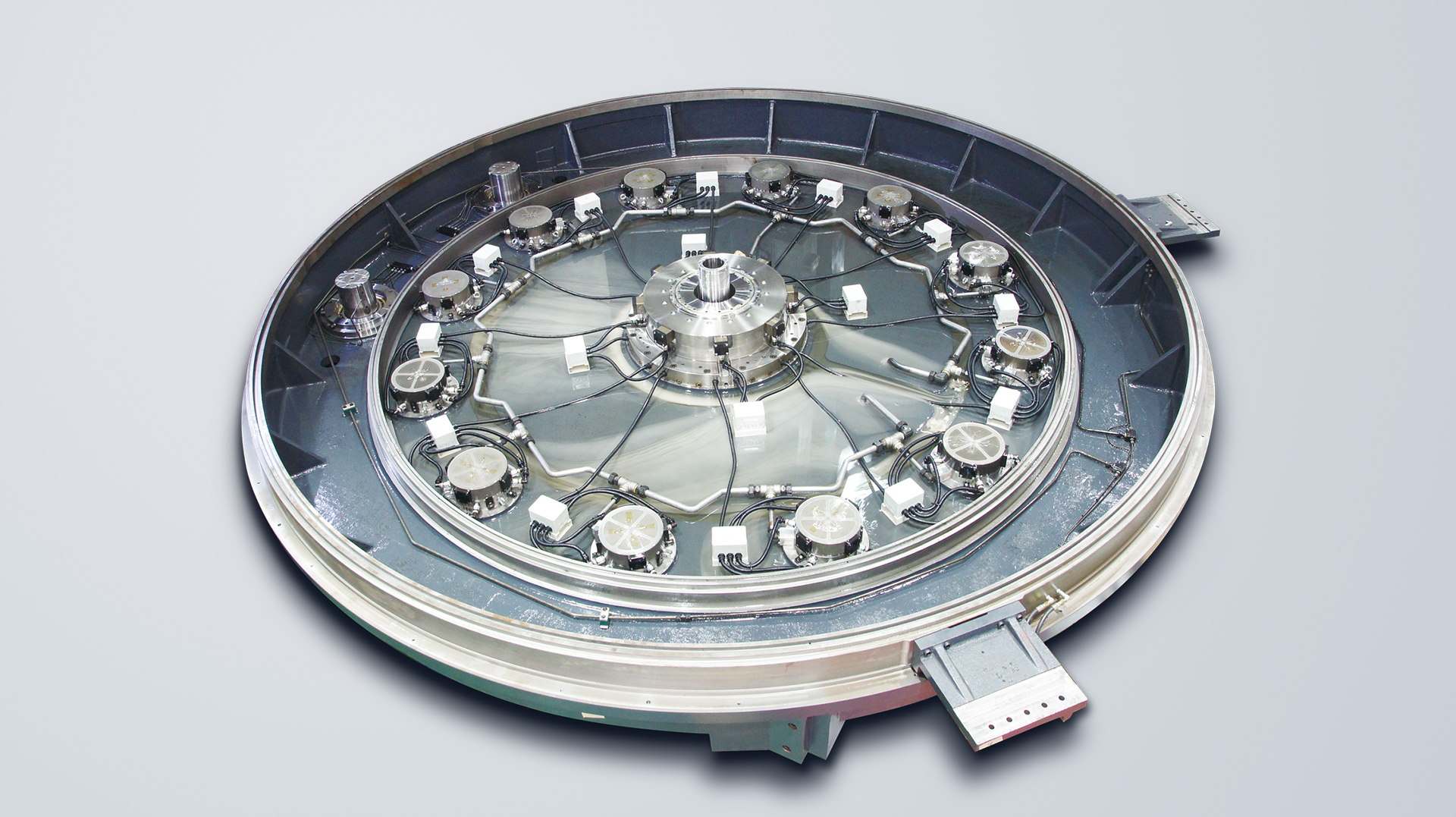

- Optional 16T / 24T umbrella-type tool magazine available based on requirements.

- High-power spindle motor drives a 2-speed gear box, delivering an impressive torque output of 347,000 Nm (GVB-5000).

- The workpiece spindle adopts an ultra-rigid crossed roller bearing / hydrostatic bearing design (models GVB-5000 and above).

Features

High Rigidity Structure

The Ultimate Machining Power

High-performance Spindle

Model Variations

- Tooling spindle

- C-axis

Tooling Spindle

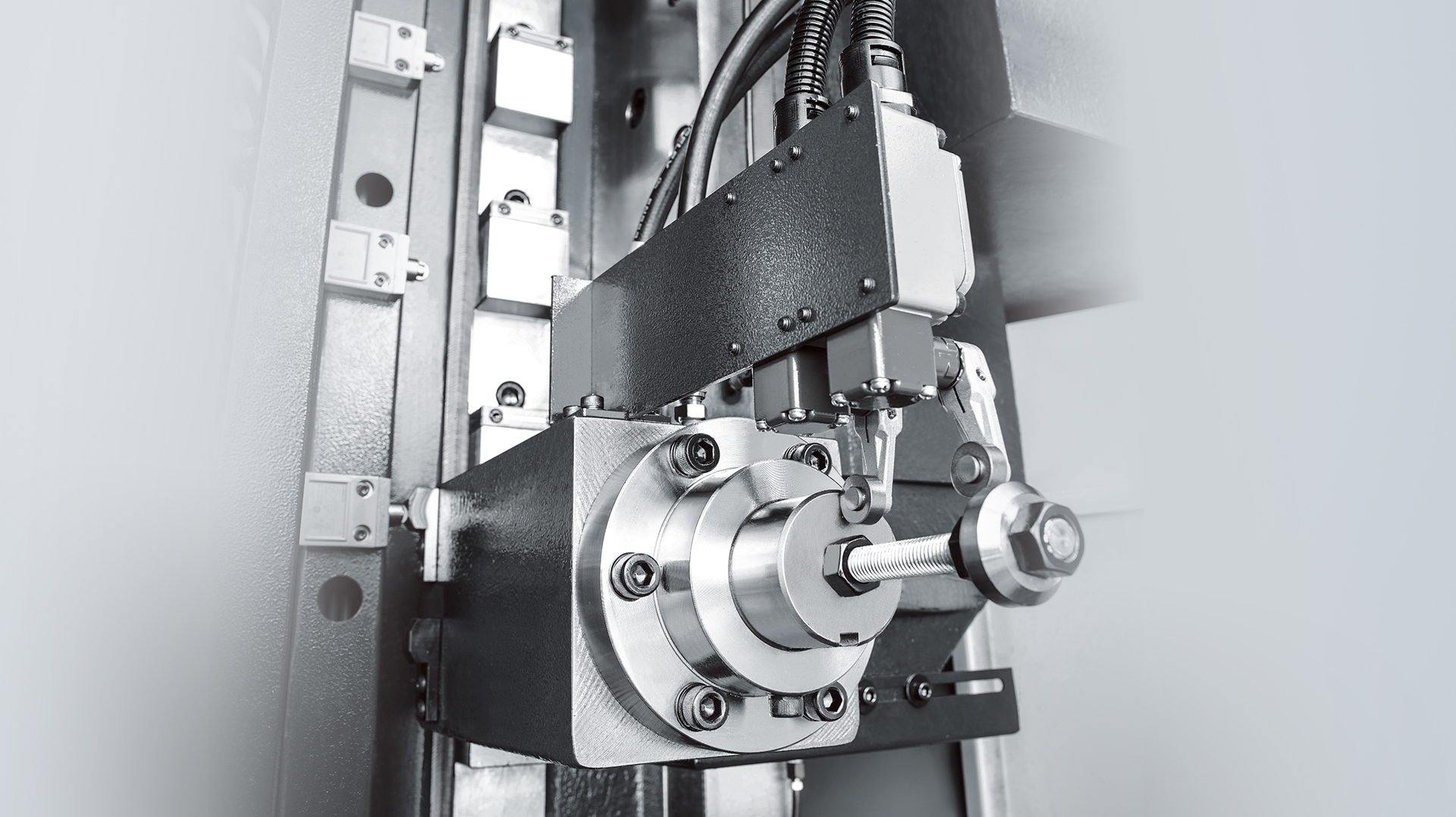

- Equipped with NN-type Japanese roller bearings to provide outstanding characteristics such as high rigidity, high precision, and long service life.

- The high reduction ratio 2-speed gear box uses high hardness alloy with forced oil-feed for lubrication and coolant; the gear box can maintain normal operation and low wear even under long hours of low-speed, high-torque working conditions.

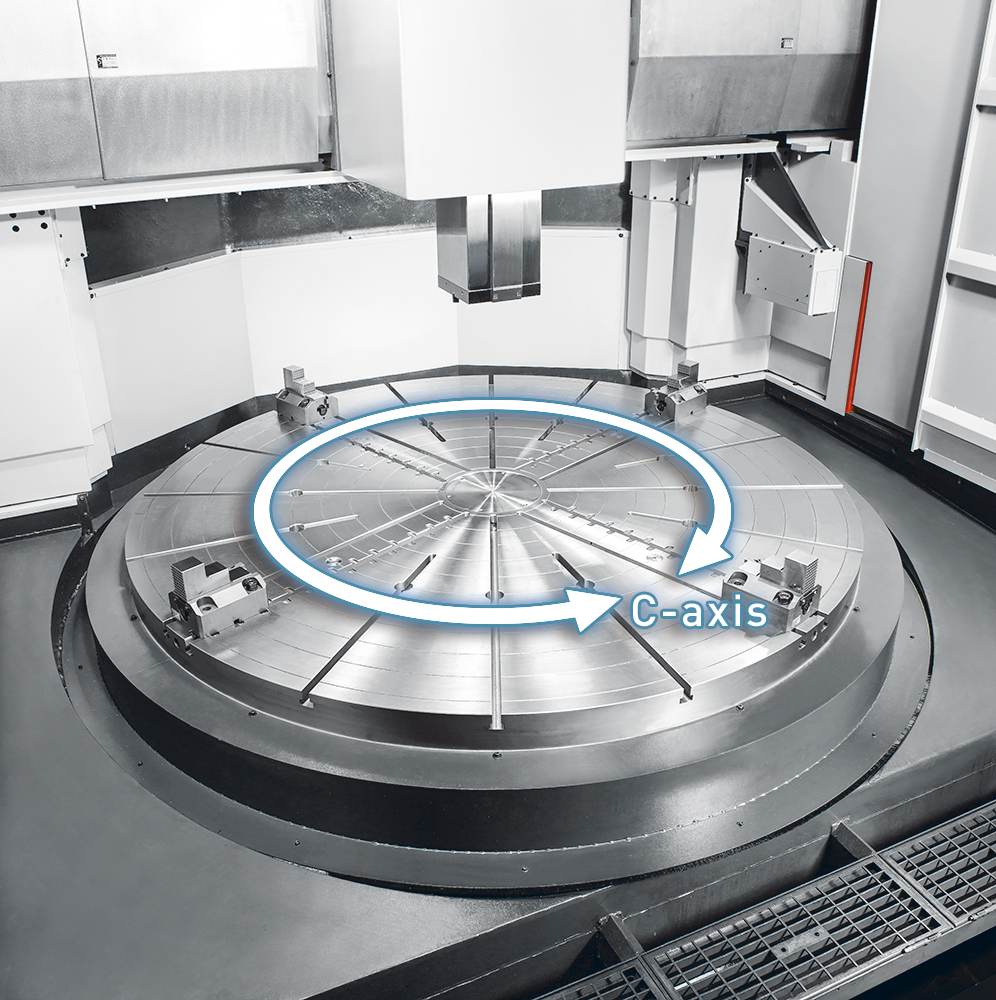

C-axis

-

Cf-axis (GVH series)

The Cf-axis and disk brake system provides the most rigid and powerful type of C-axis in the market today. The surface accuracy and dynamic accuracy can be maintained under heavy duty cutting conditions. -

Cs -axis (GVB series)

The Cs-axis is driven by double spindle motors which eliminates gear backlash while providing double torque output. The repeatability can reach up to ±5" and positioning accuracy can reach up to ±7.5" under normal working conditions.