GVI

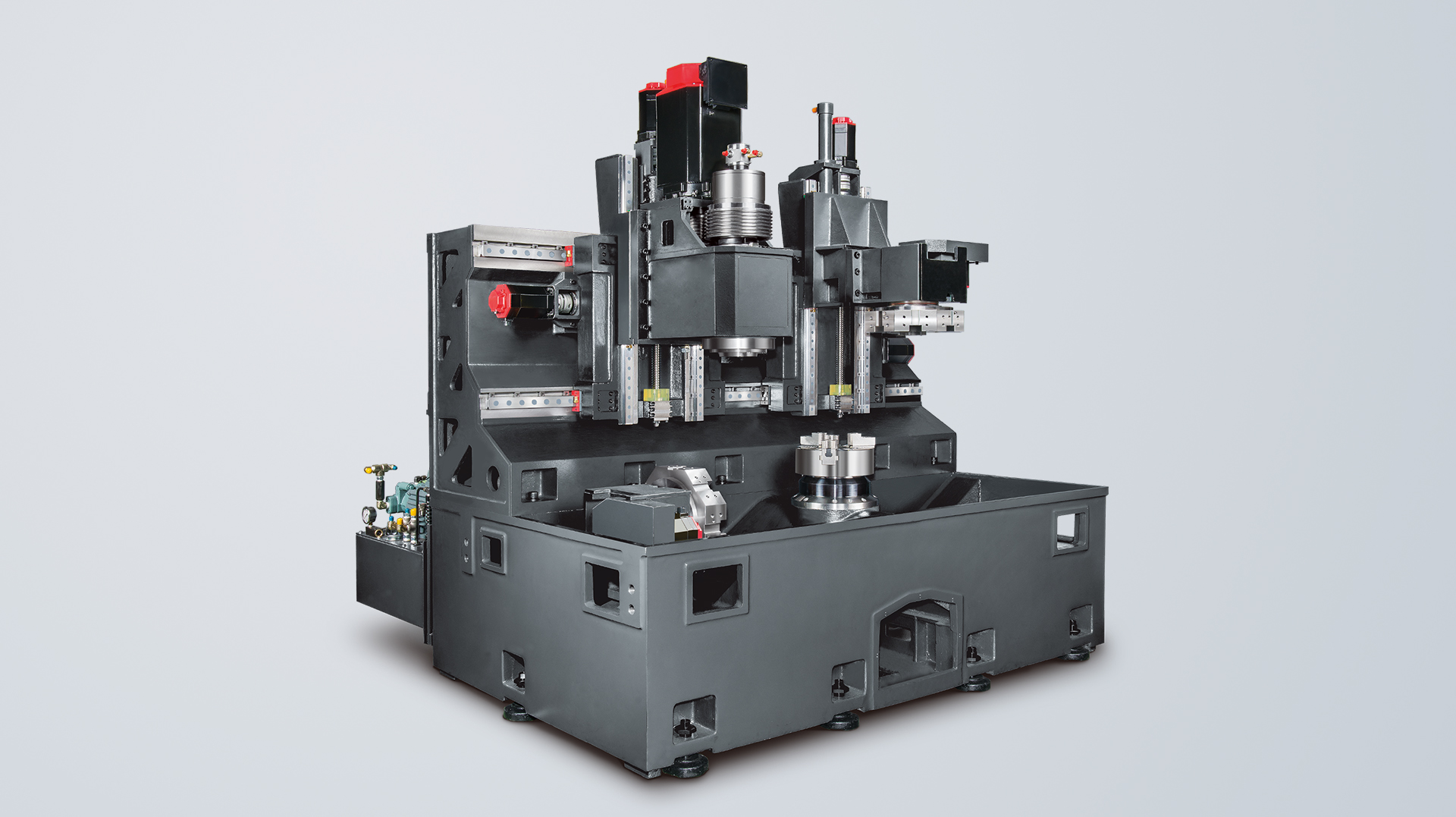

The GVI-350 series features an advanced Inverted vertical design on twin spindles and turrets. When integrated with an automated loading and unloading system, it enables fully automated processes from part loading, first-operation machining, part transfer, second-operation machining, to unloading. This setup not only significantly reduces labor requirements but also meets stringent demands for high-precision and high-efficiency mass production.

- Outstanding mass production capability enables both front and back machining of the workpiece to be completed on a single machine.

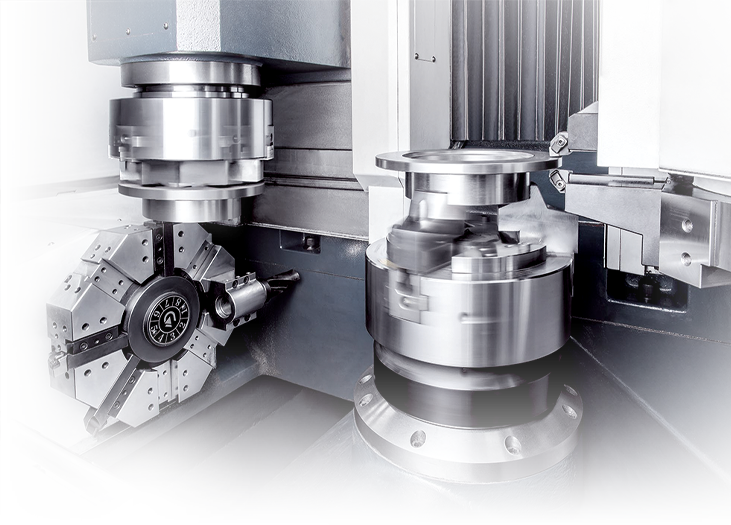

- Inverted vertical design on twin spindles and turrets.

- The base and column are integrally cast using high-rigidity Meehanite casting structure.

- The column features a thick ribbed L-type structure, providing a highly rigid foundation for all moving components.

- X / Z axes adopt roller linear guideways, offering excellent control and support rigidity.

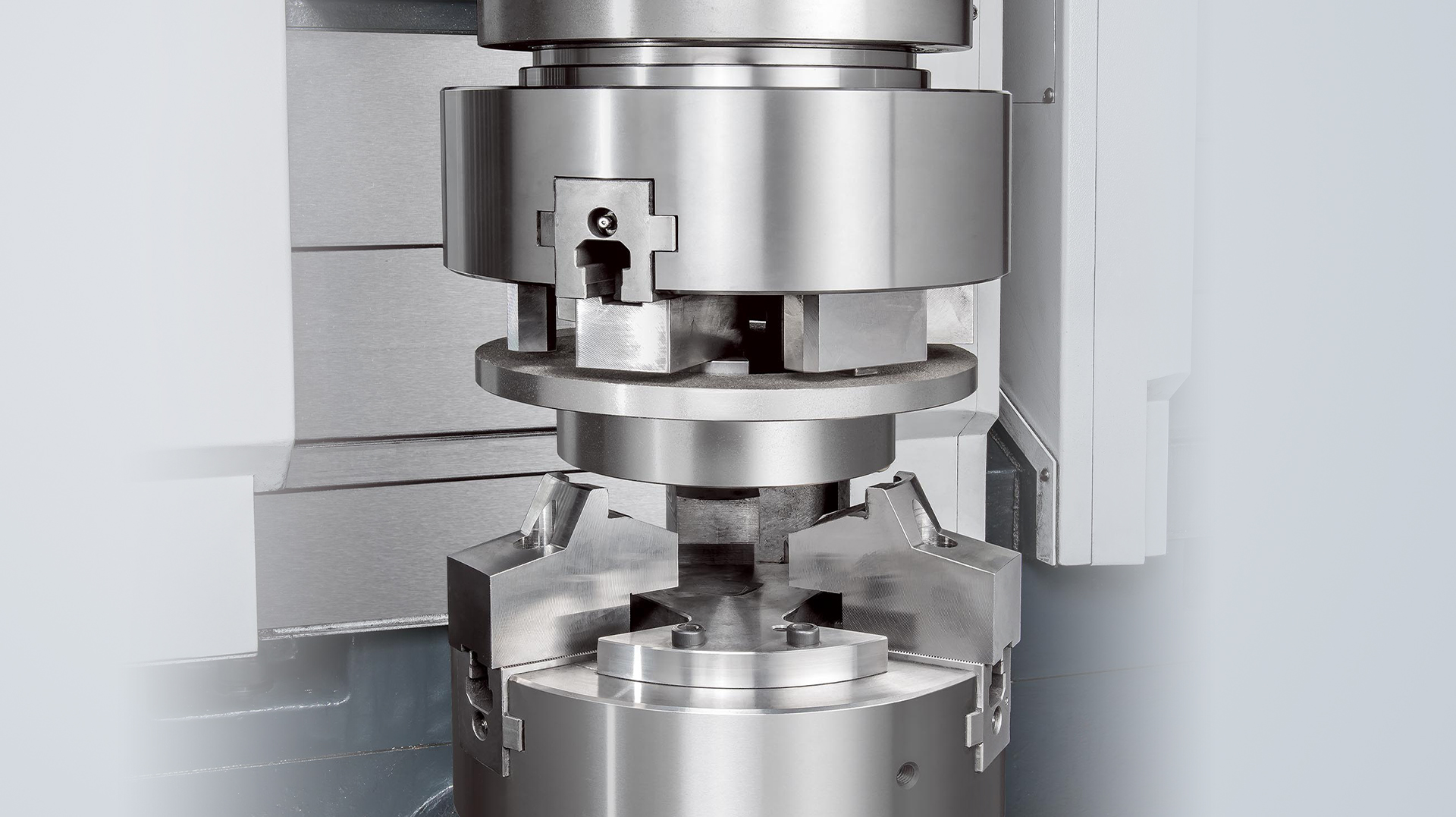

- Spindle 2 performs back-side machining directly after synchronized part transfer from spindle 1, eliminating the need for manual intervention or additional mechanisms, and significantly enhancing machining efficiency.

- Spindle 1 features an inverted design, allowing chips to fall directly into the chip tray by gravity, preventing chip accumulation.

- Both the upper and lower turrets can be equipped with 8 tools, and optionally upgraded to 12-station live tool turrets based on application requirements.

- Both spindle 1 and 2 offer a maximum speed of 3,000 rpm.

- With a powerful 14,200 kgf hydraulic clamping force, the 3-jaw chuck provides secure and stable holding for heavy-duty cutting, even with 20 kg workpieces.

Features

High Rigidity Structure

The Ultimate Machining Power

High-performance Spindle

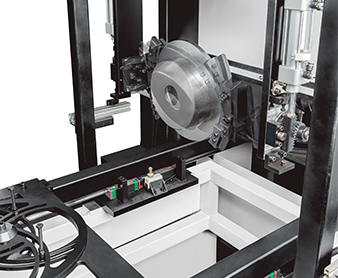

Automatic loading for spindle 1

Twin spindles synchronous cutting

Twin spindles synchronized feeding and part transfer

High-rigidity structural design

Live tooling turret

C-axis

Live Tooling Turret

- Live tooling turret is driven by spindle motor with transmission mechanism which provides abundant 4.5 kW output can easily complete any task of milling, drilling and tapping.

- The 12-station GOODWAY live tooling turret offers 12 stations available for live tooling ( live tooling tools rotate in working position only ) and features a non-lifting turret disk.

C-axis

- With optional C-axis control and live tooling turret, the GVI series capable of performing turning, milling, drilling, and tapping operations on a single machine. This eliminates errors caused by workpiece transfer between machines, while significantly reducing cycle time and labor requirements.

- High-torque, built-in type Cs-axis combined with a high-precision magnetic ring design. Offers easy operation and significantly faster indexing speeds compared to the Cf axis.