GVF

Packed with the latest machine tool technology and high-quality components, the GOODWAY GVF series vertical CNC lathes feature a high-rigidity fixed-beam structure and a high-torque, gear-type workpiece spindle, delivering ultra-heavy cutting capability that outperforms machines in its class. They fully satisfy the machining requirements of large workpieces in industries such as aerospace and energy. In addition, optional live tooling spindles, Cf-axis, and various attachment heads give this series multi-tasking capability for turning, milling, and drilling on both end surface and cylindrical surfaces—easily meeting your cutting needs today and in the future.

- The preferred machine for industries such as shipbuilding, wind turbines, construction equipment, and aerospace.

- The fixed beam structural design provides the highest structural rigidity and damping capability for the entire machine.

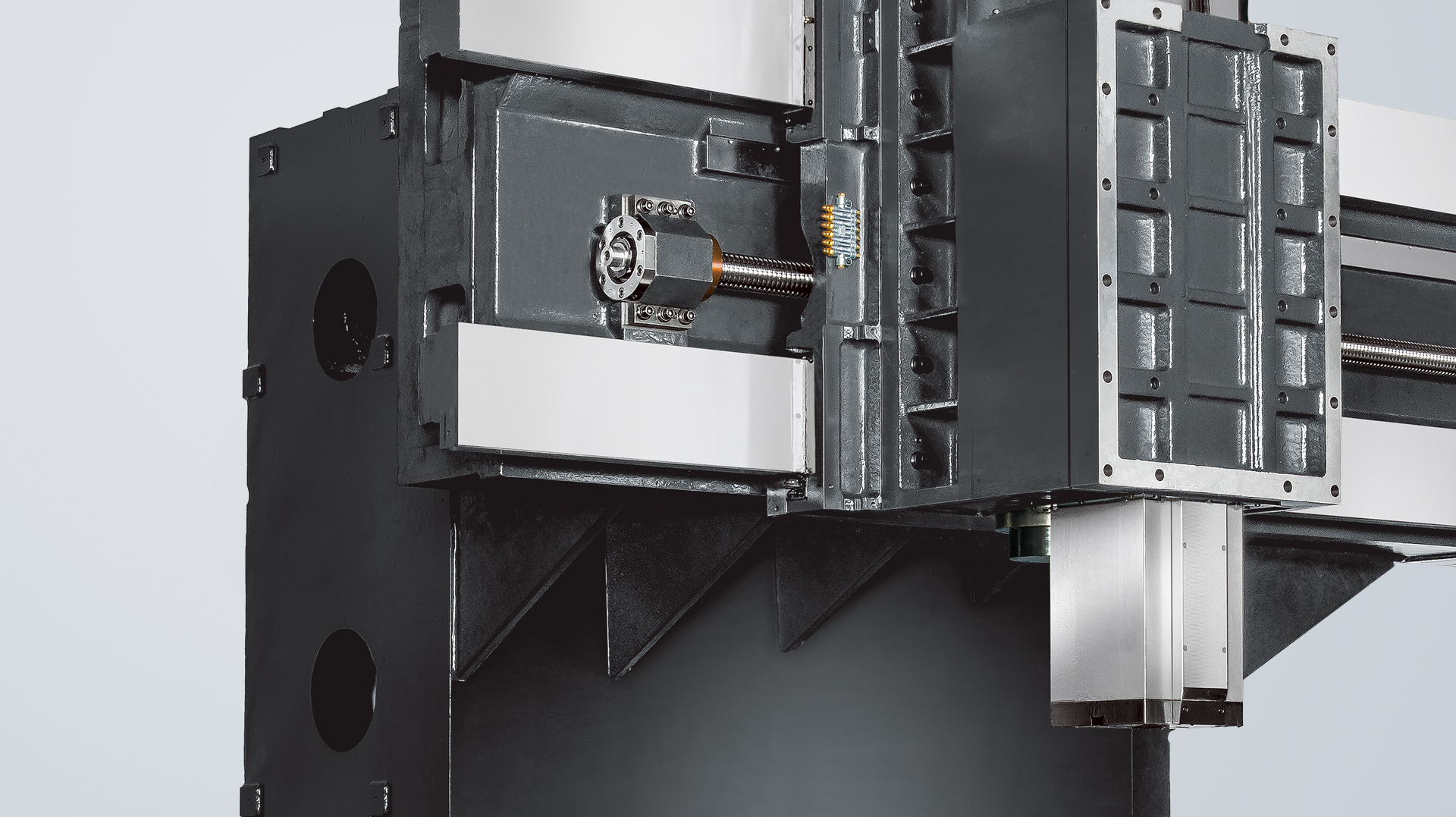

- X and Z axes feature over-sized box ways combined with a wide-span design.

- The base and column are integrally cast using high-rigidity Meehanite casting structure.

- The robust column, combined with optimized reinforcement rib design, provides ample support rigidity for the headstock.

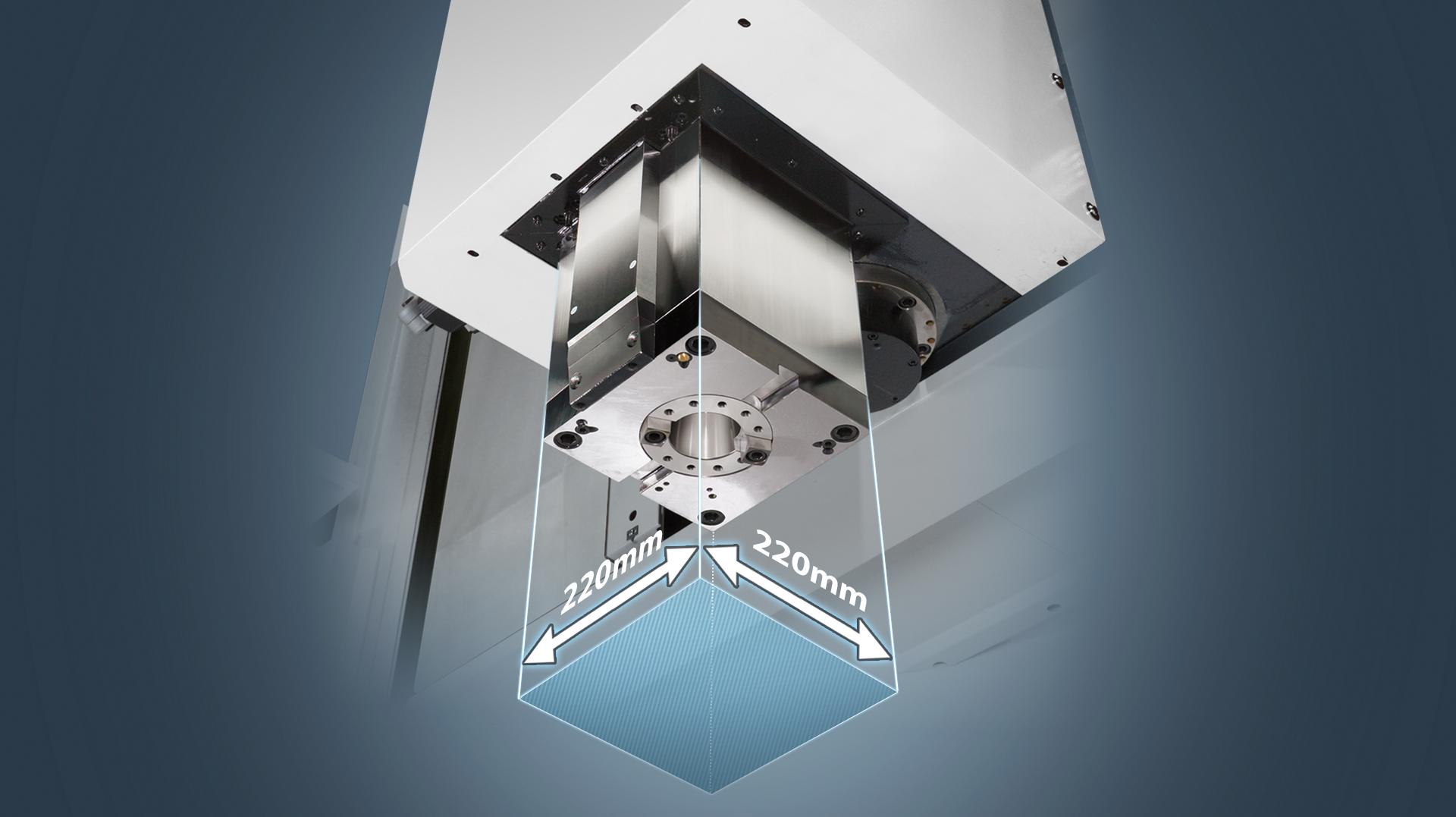

- The live tooling spindle features a 2-speed gear box design, delivering high torque output. Tool spindle speed reaches up to 2,400 rpm (milling function optional).

- Optional 12T / 16T / 24T umbrella-type tool magazine available based on requirements.

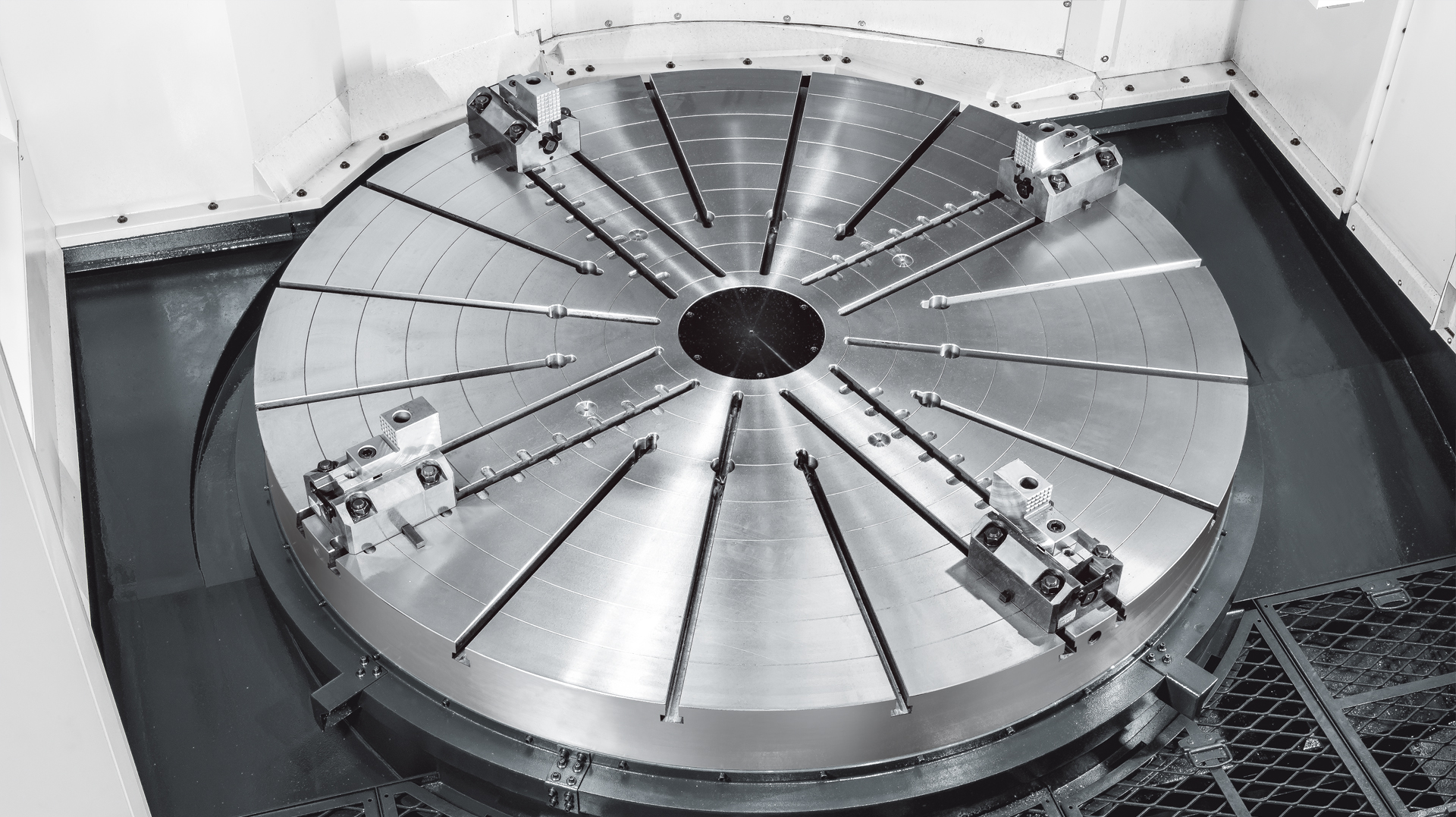

- A 45 kW spindle motor drives a two-speed gearbox, delivering spindle torque output of up to 23,900 Nm.

- The spindle bearings use a high-rigidity, high-precision crossed roller bearing design.

Features

High Rigidity Structure

The Ultimate Machining Power

High-performance Spindle

Model Variations

- Tooling spindle

- C-axis

Tooling Spindle

- Equipped with NN-type Japanese roller bearings to provide outstanding characteristics such as high rigidity, high precision, and long service life.

- The high reduction ratio 2-speed gear box uses high hardness alloy with forced oil-feed for lubrication and coolant; the gear box can maintain normal operation and low wear even under long hours of low-speed, high-torque working conditions.

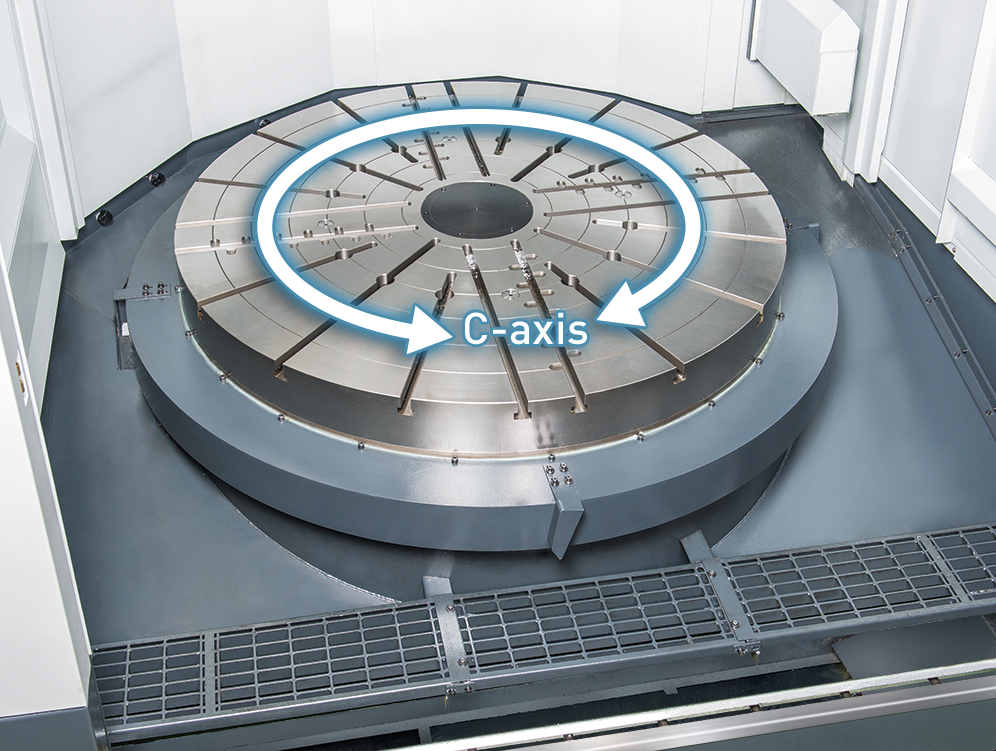

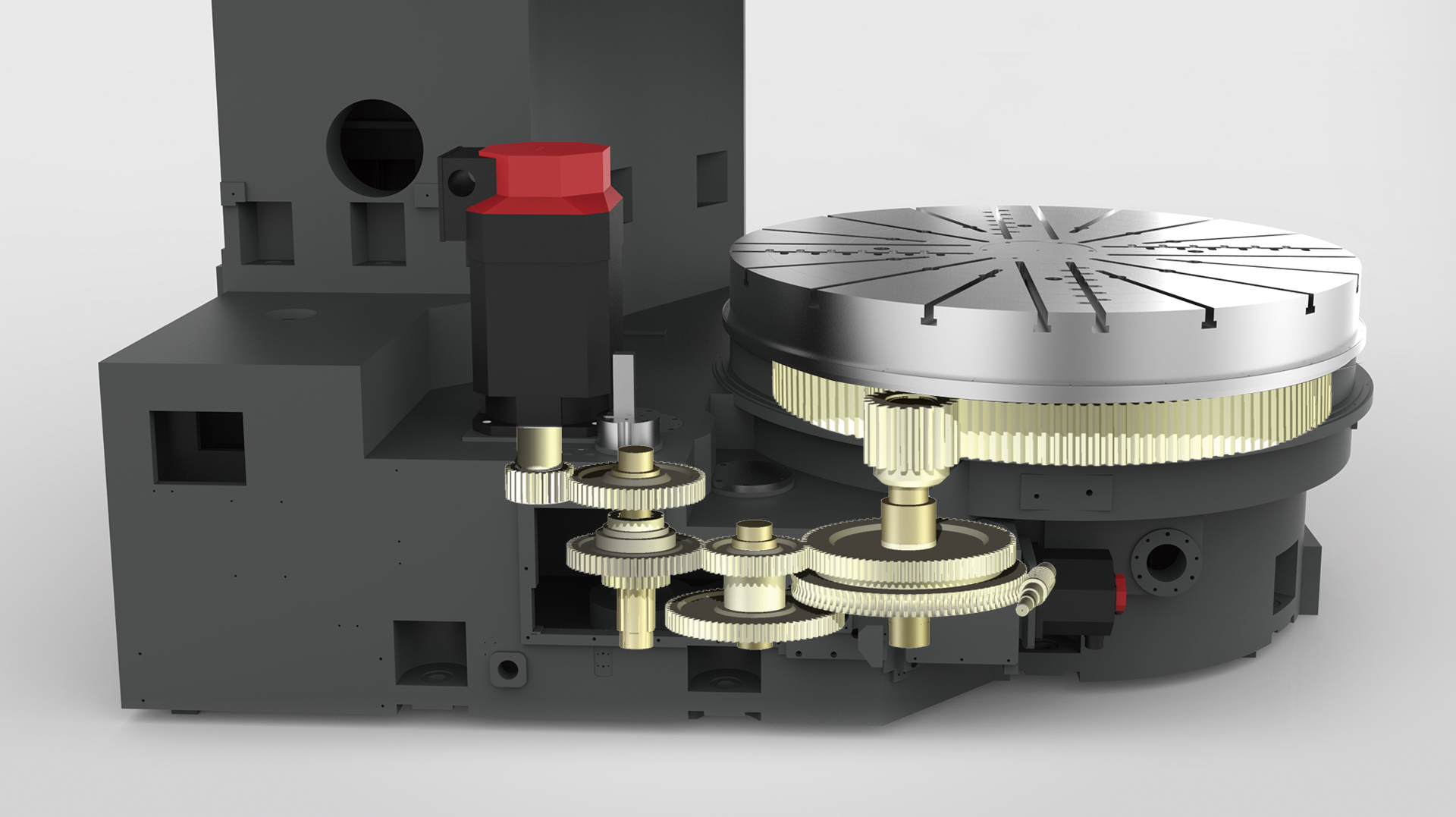

C-axis

- The Cf-axis features a high-resolution servo-driven worm gear system that ensures exceptional positioning precision, simplified backlash adjustment, and ultra-fine indexing accuracy of 0.001°.