GV-780

Packed with the latest machine tools technology and high precision turning capabilities, the GOODWAY GV-780 series ultra performance vertical CNC turning center combines a super-rigidity structure and precision roller linear guideways with a servo indexing turret and powerful spindle ( max. torque up to 1,050 Nm ). These series features a compact machine size with heavy duty turning capabilities. The optional live tooling turret, C-axis, dual-face turning holders and work-piece balancing analyzer allows the GV-780 series to be able to complete turning, milling, drilling, tapping, dual-face machining and work-piece balancing analyzing in one single machine.

- High performance, high reliability, and a footprint of only approximately 6.3 m2.

- The optimal manufacturing solution for brake discs, brake drums, gears, wheels, hubs, and valves.

- The base and column are integrally cast using high-rigidity Meehanite casting structure.

- X / Z axes adopt roller linear guideways, offering excellent control and support rigidity.

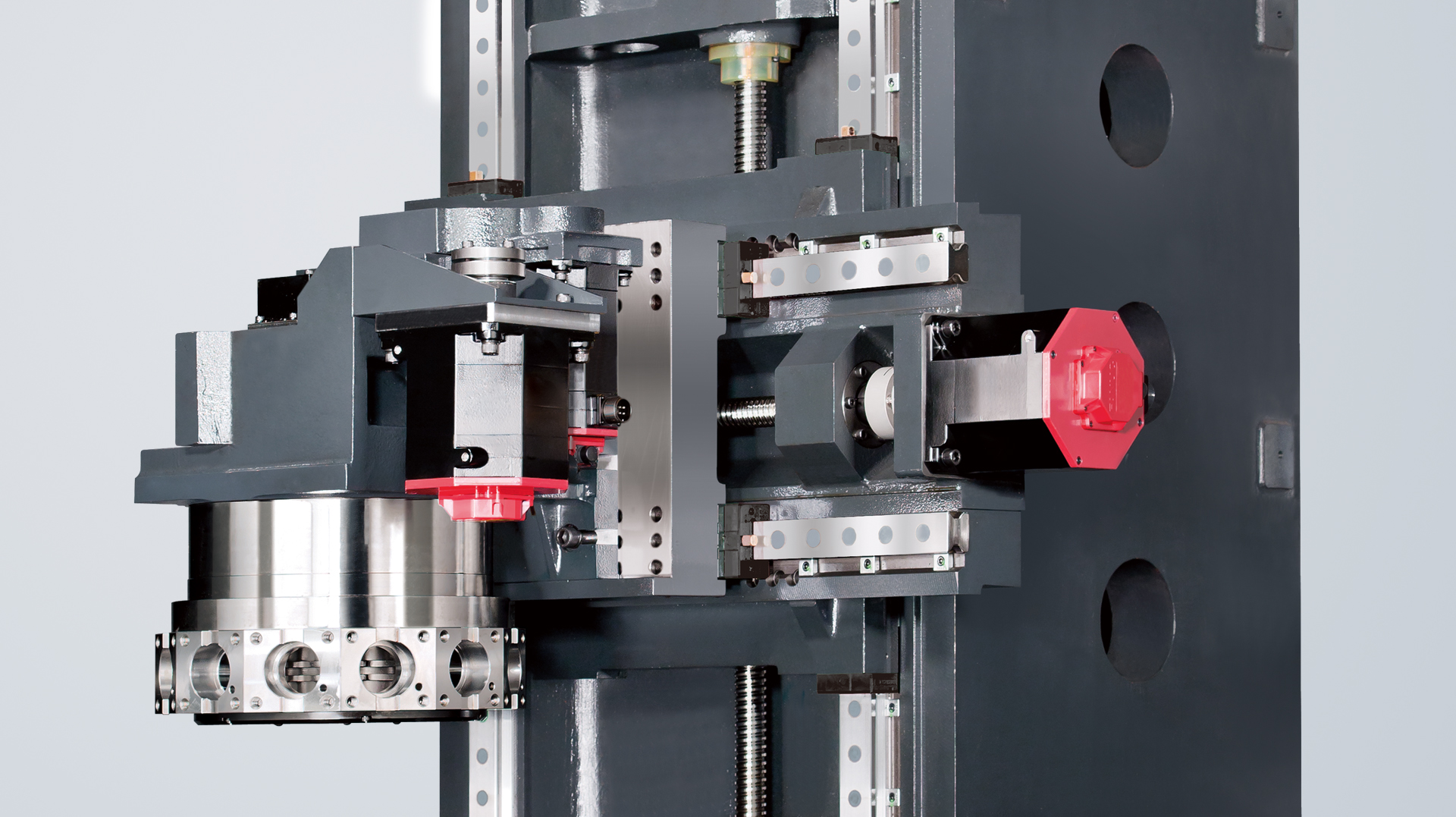

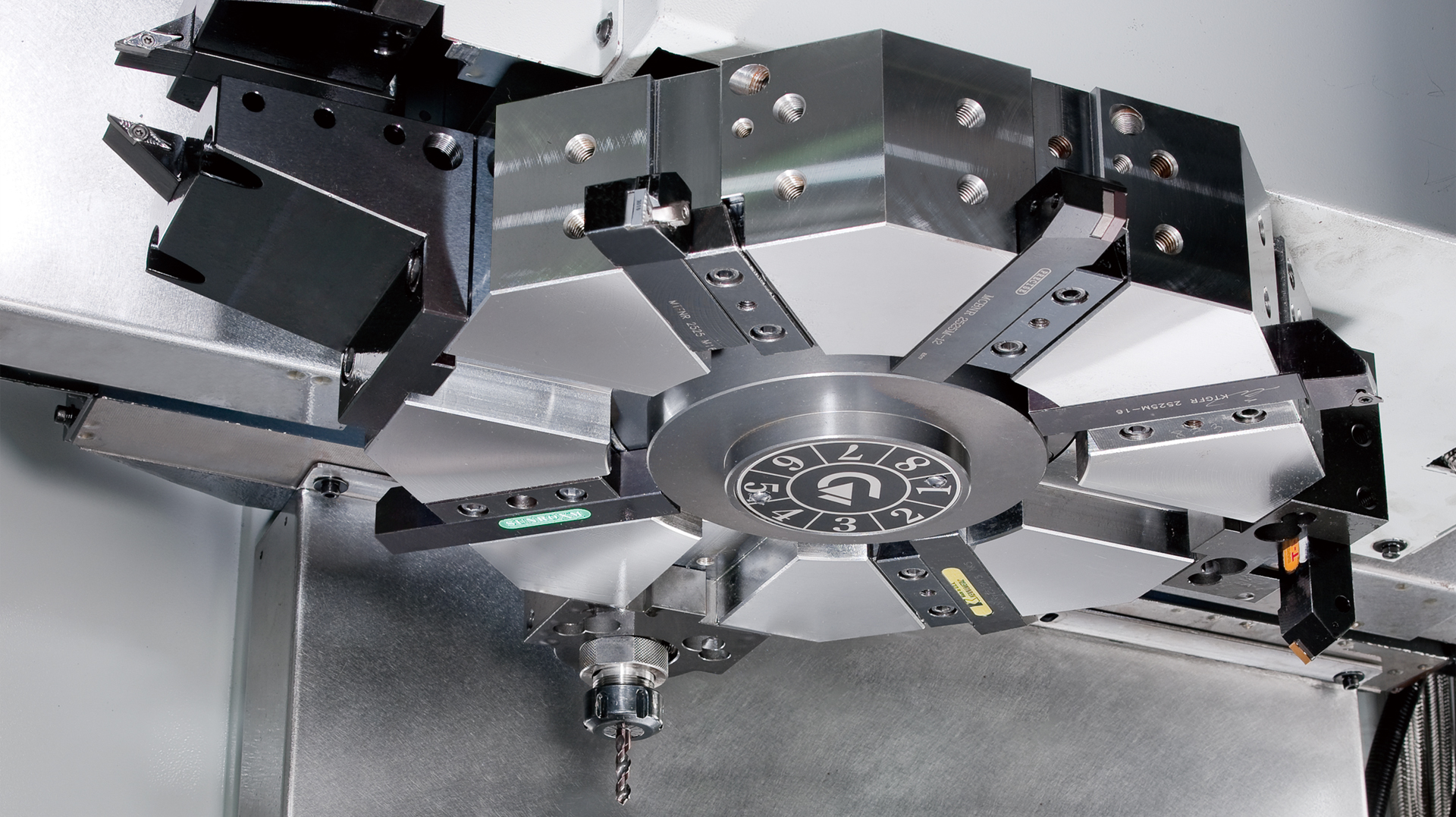

- 8 or 12-station servo indexing turret provides rapid tool indexing and excellent cutting rigidity.

- The GOODWAY dual-face turning holder allows both sides of a work-piece to be machined at the same time while, ensuring parallel precision of the surface.

- With an optional live tooling turret and C-axis, the GV-780 series is capable of performing turning, milling, drilling, and tapping operations on a single machine.

- 22 kW high-torque spindle motor delivers exceptional cutting power and stability.

Features

High Rigidity Structure

The Ultimate Machining Power

High-performance Spindle

Model Variations

- Live tooling turret

- C-axis

Live Tooling Turret

- Live tooling turret and C-axis control capabilities on the GV-780 series allows the machine to perform multitasks on a work-piece, such as turning, milling, drilling and tapping. This eliminates manpower and cycle time, while reducing accuracy lost, which will occur if the part is moved from machine to machine.

- The 12-station GOODWAY live tooling turret offers 12 stations available for live tooling ( live tooling tools rotate in working position only ) and features a non-lifting turret disk.

- GOODWAY's live tooling turret utilizes advanced servo indexing technology to achieve 0.2 second indexing for adjacent stations and 0.5 second for stations at the opposite end of the disk.

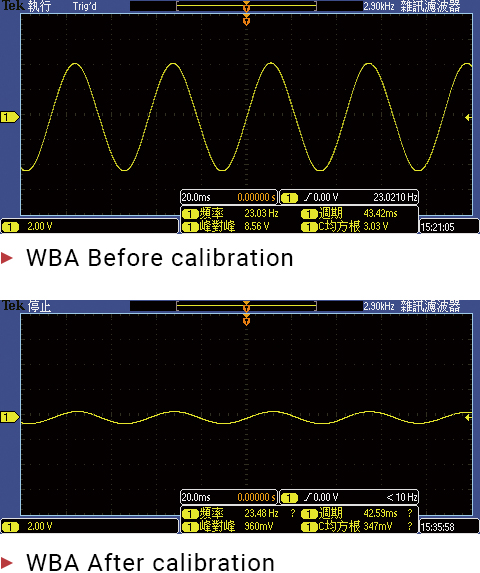

Work-piece Balancing Analyzer ( WBA )

- Increasing productive efficiency and streamlining operations have always been GOODWAY's research and development concept. The GOODWAY Work-piece Balancing Analyzer ( WBA ) is based on the developing foundation of our multi-tasking turning centers and University - Industry Cooperation. And now we combine them together to accomplish for a higher level of efficiency and streamlining.