GV-1000

With 50 years of experience in lathe manufacturing, GOODWAY is pleased to introduce our GV-1000 Vertical CNC Turning Center. With a combination of ultra-high power performance, super rigid construction, and high speed machining, the GV-1000 provides the turning and milling capacity for the dynamic demands of today and tomorrow's market.

- Compact machine size with powerful cutting capability.

- Milling performance is comparable to that of a BT40 specification machining center (optional live tooling turret and C-axis).

- One-piece ultra-rigid column.

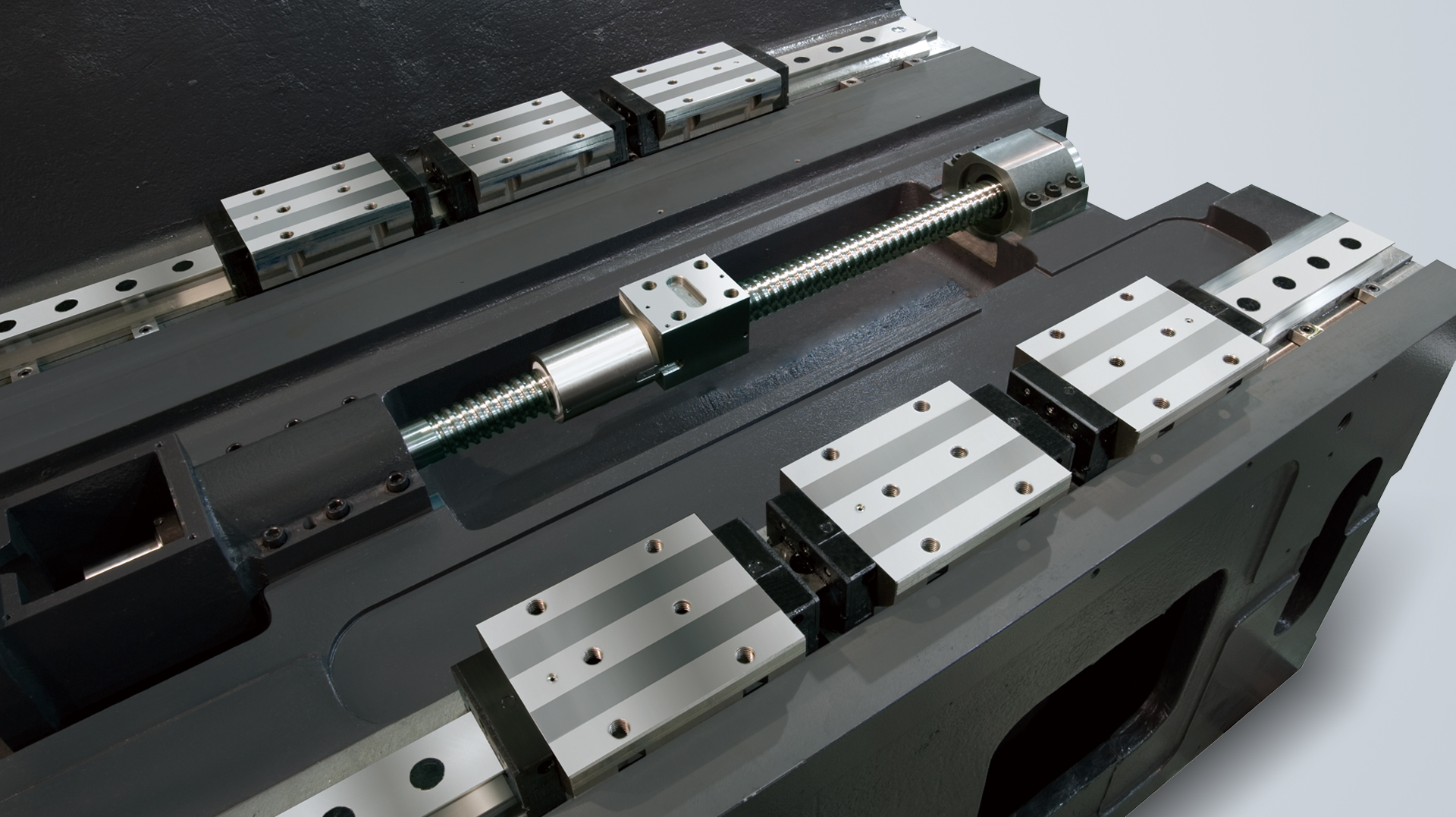

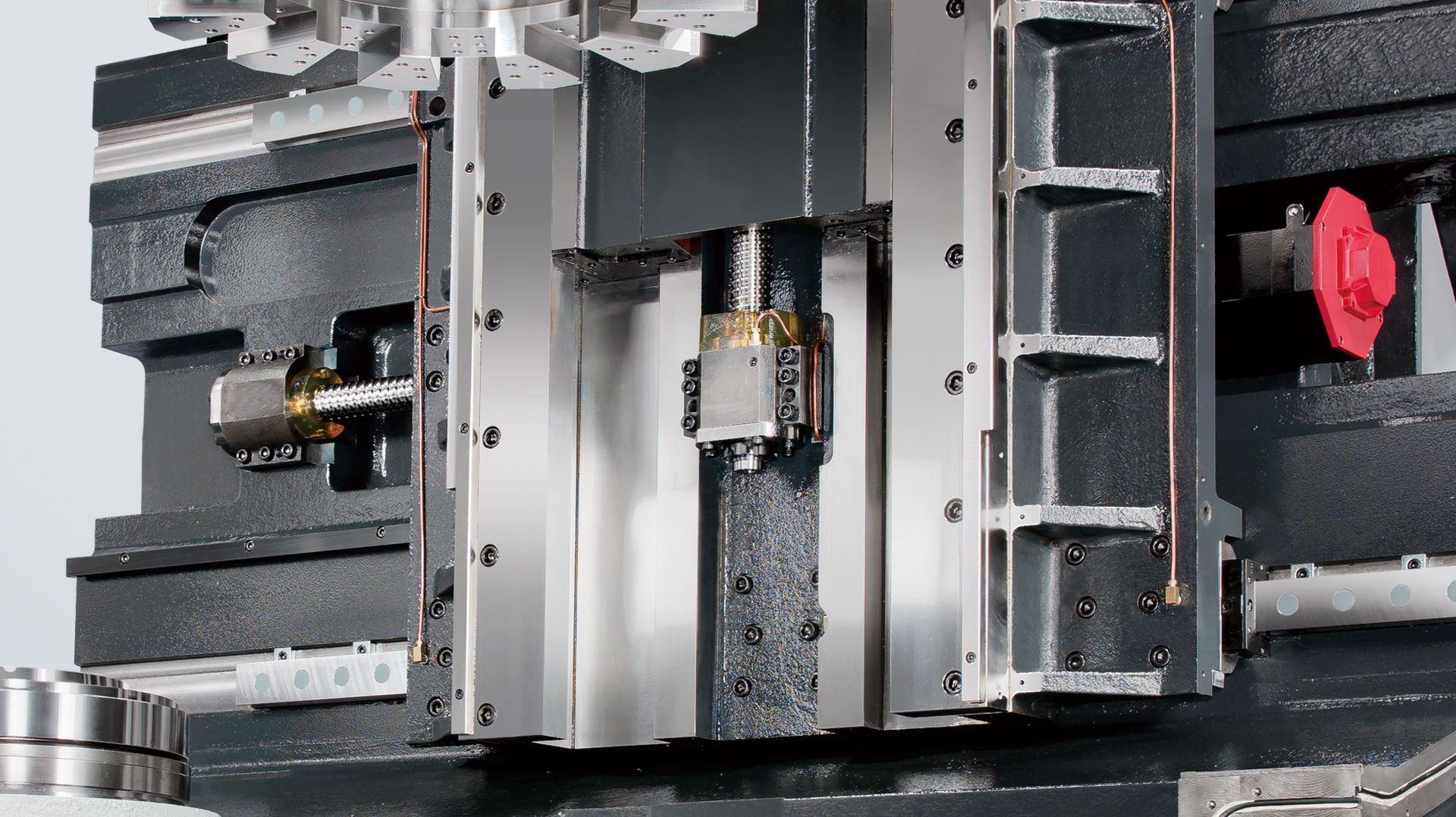

- The X-axis features a roller-type linear guide design, offering excellent control and support rigidity.

- Z axes feature over-sized box ways combined with a wide-span design.

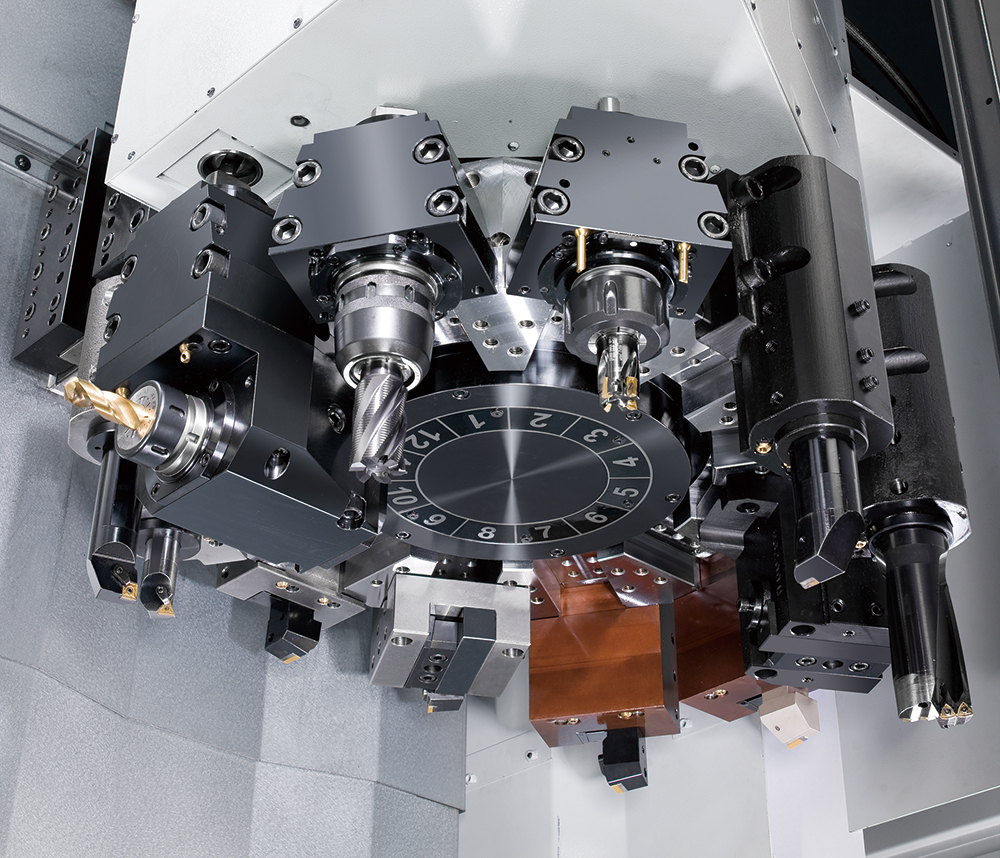

- 12-station servo-indexed turret with high rigidity and extra-large turret disk diameter.

- Optional ER50 12-tool live tooling turret provides exceptionally powerful milling and drilling performance.

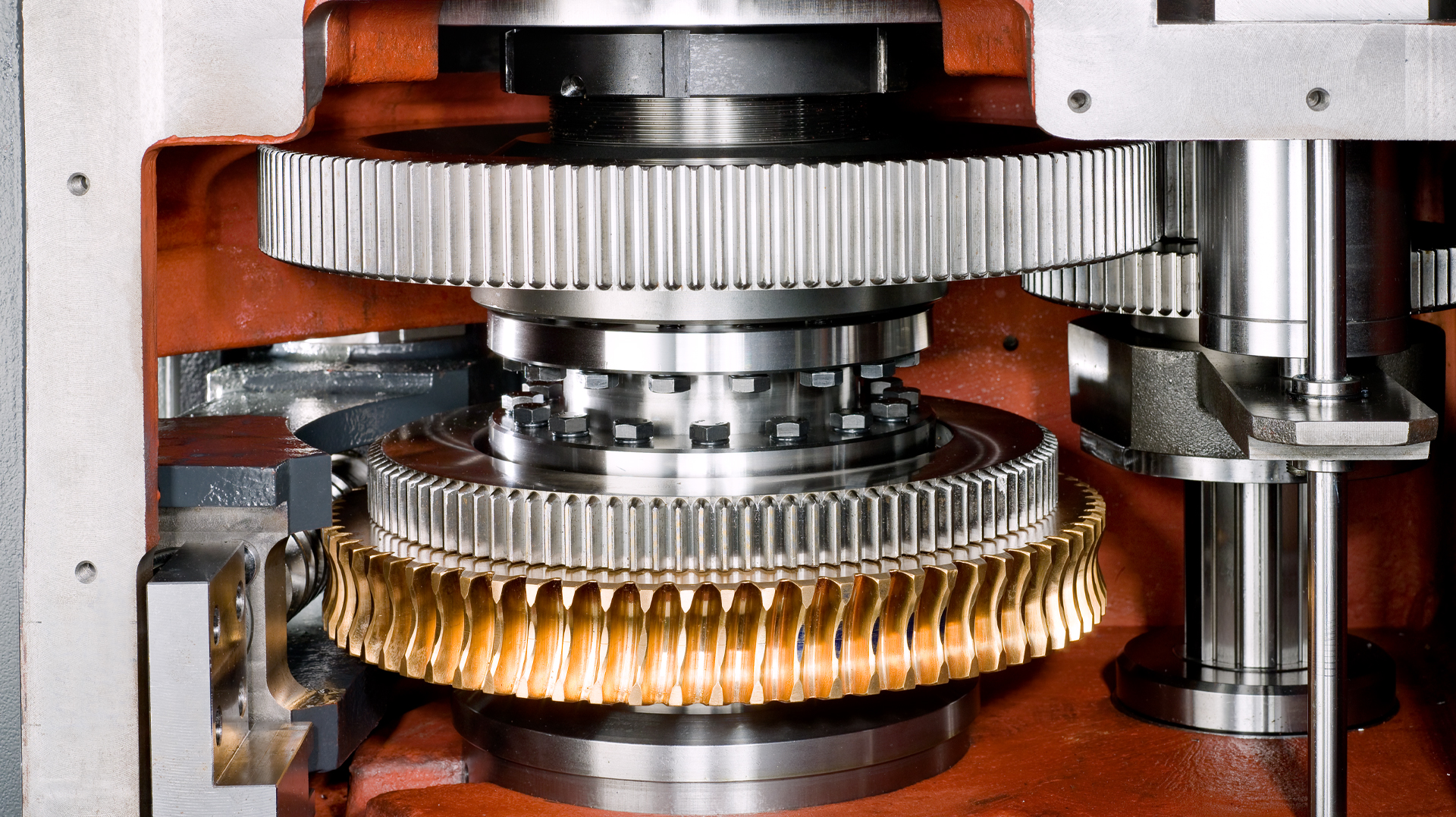

- Equipped with a 30 kW spindle motor and 2-speed gearbox for up to 3,700 Nm of torque output.

Features

High Rigidity Structure

The Ultimate Machining Power

High-performance Spindle

Model Variations

M

- Live tooling turret

- C-axis

12-station servo turret

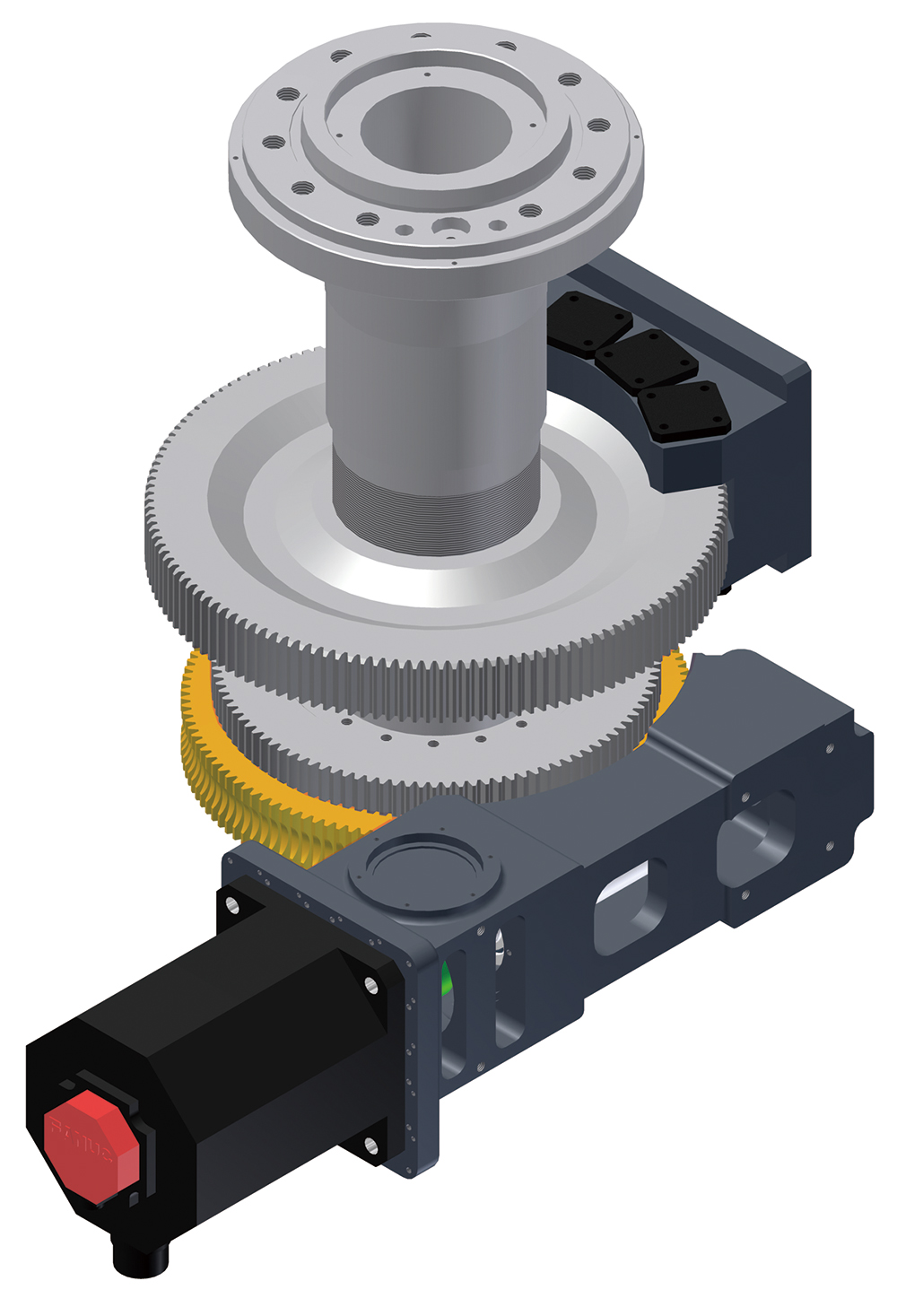

High torque 2-speed gear box

Heavy-duty roller type linear guideways with oversized blocks

High rigidity box ways (Z-axis)

Live tooling turret

C-axis

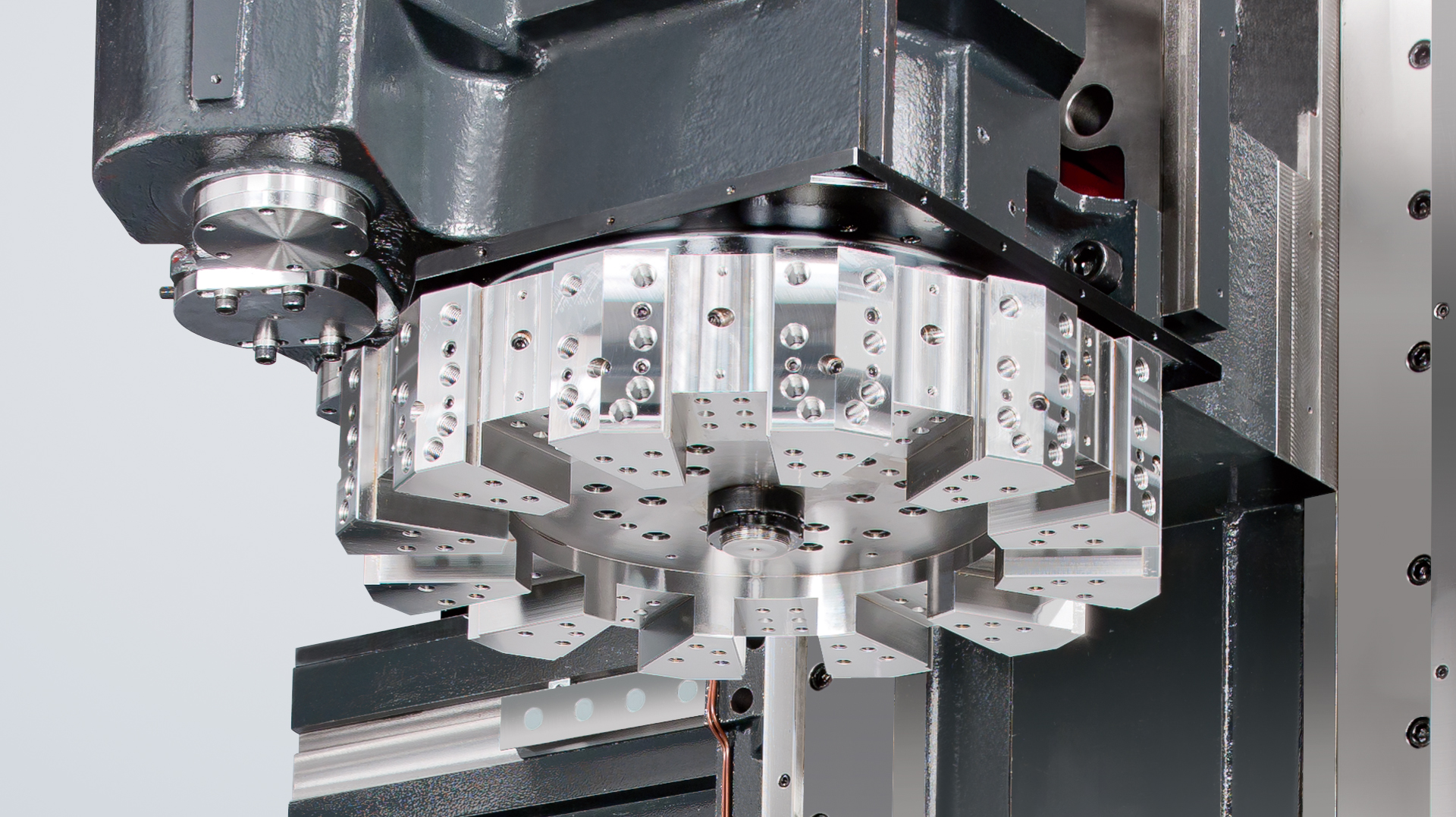

Live Tooling Turret

- High precision Ø320 mm turret disk with Japanese curvic coupling for superior tool indexing performance.

- The 12-station GOODWAY live tooling turret offers 12 stations available for live tooling ( live tooling tools rotate in working position only ) and features a non-lifting turret disk.

C-axis

- The Cf-axis and disk brake system available on the GV-1000 series provides the most rigid and powerful type of C-axis on the market today. The Cf-axis adopts a worm gear drive system, offering precise transmission, easy backlash adjustment, and a minimum indexing accuracy of 0.001°.

- Working with the live tooling turret, Cf-axis and disk brake system enables the machine to perform multiple tasks, such as drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations.