GV-1

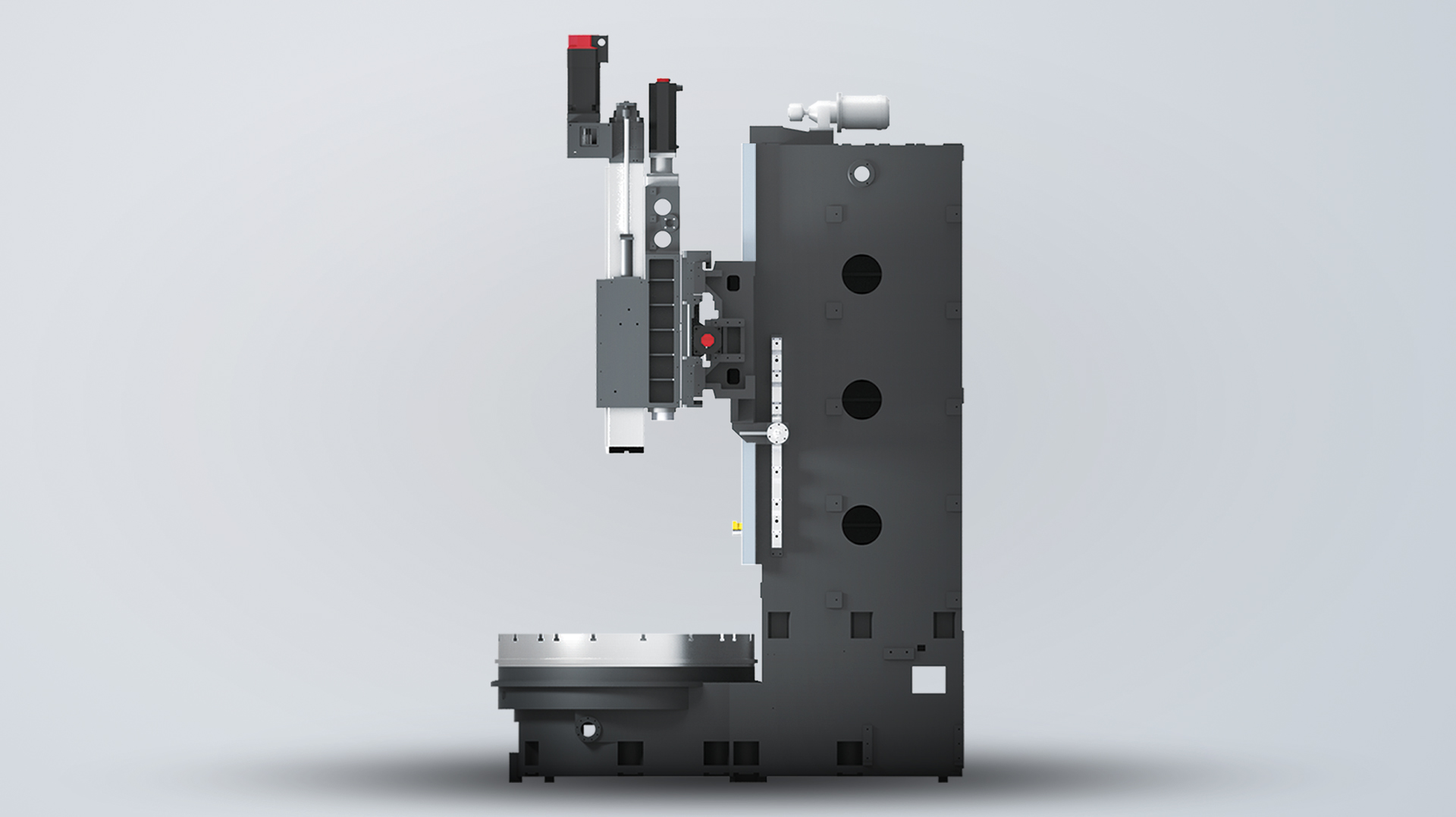

With a combination of ample machining range, exceptional load capacity, and a flexible moving cross rail structure, this series offers superior mechanical rigidity and heavy cutting capability compared to other machines in the same class. The GV-1 series easily handles the machining demands of heavy workpieces or difficult-to-cut materials.

- The preferred machine for industries such as shipbuilding, wind turbines, construction equipment, and aerospace.

- The W-axis moving cross rail structure allows the series to perform machining with the shortest ram overhang, ensuring the highest cutting rigidity.

- X and Z axes feature over-sized box ways combined with a wide-span design.

- The base and column are integrally cast using high-rigidity Meehanite casting structure.

- The robust column, combined with optimized reinforcement rib design, provides ample support rigidity for the headstock.

- The live tooling spindle features a 2-speed gear box design, delivering high torque output. Tool spindle speed reaches up to 2,400 rpm (milling function optional).

- Optional 12T / 16T / 24T umbrella-type tool magazine available based on requirements.

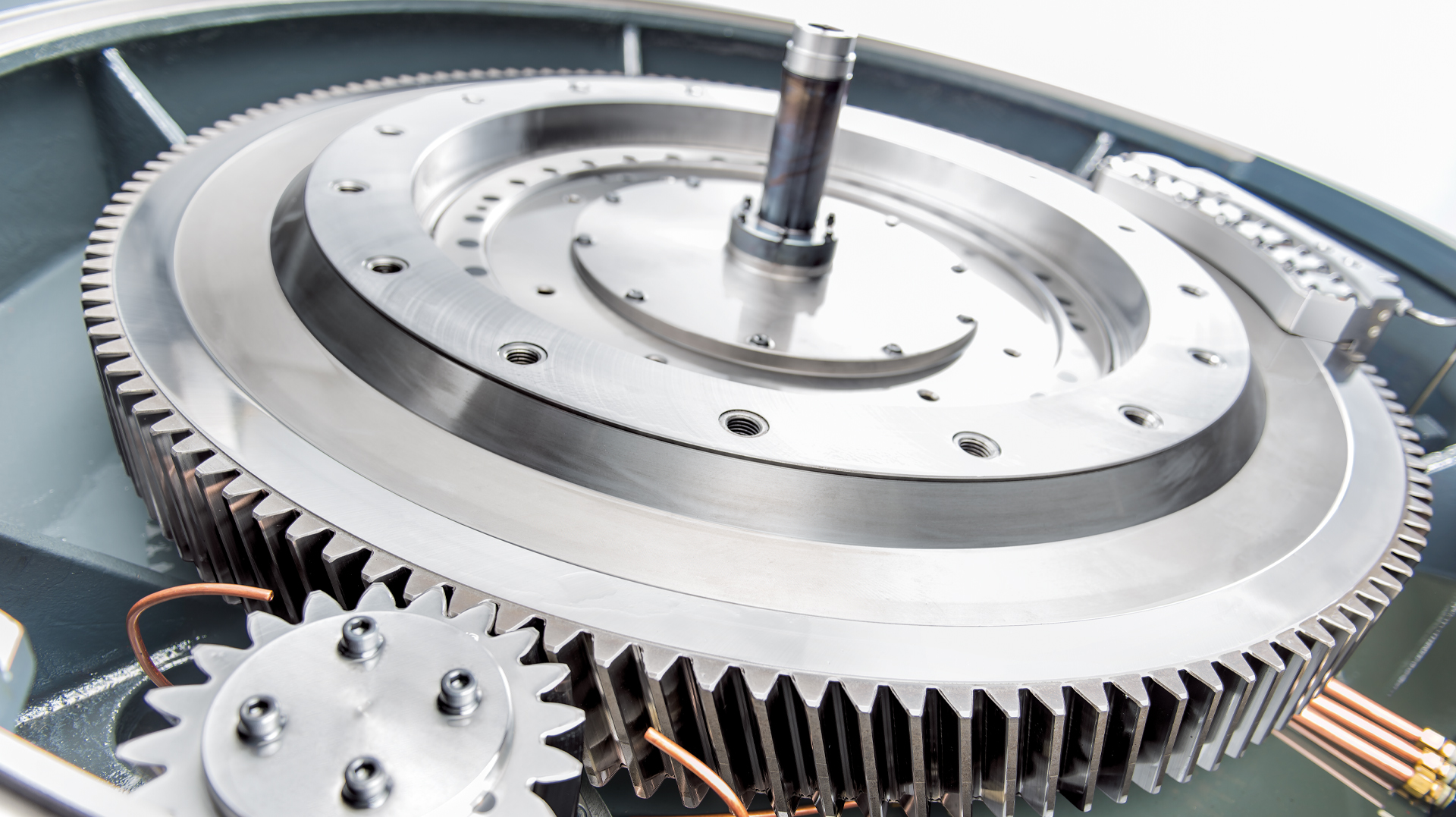

- A 45 kW spindle motor drives a two-speed gearbox, delivering spindle torque output of up to 23,900 Nm.

- The spindle bearings use a high-rigidity, high-precision crossed roller bearing design.

Features

High Rigidity Structure

The Ultimate Machining Power

High-performance Spindle

Model Variations

M

- Tooling spindle

- C-axis

Robust column structure

Work-piece spindle structure

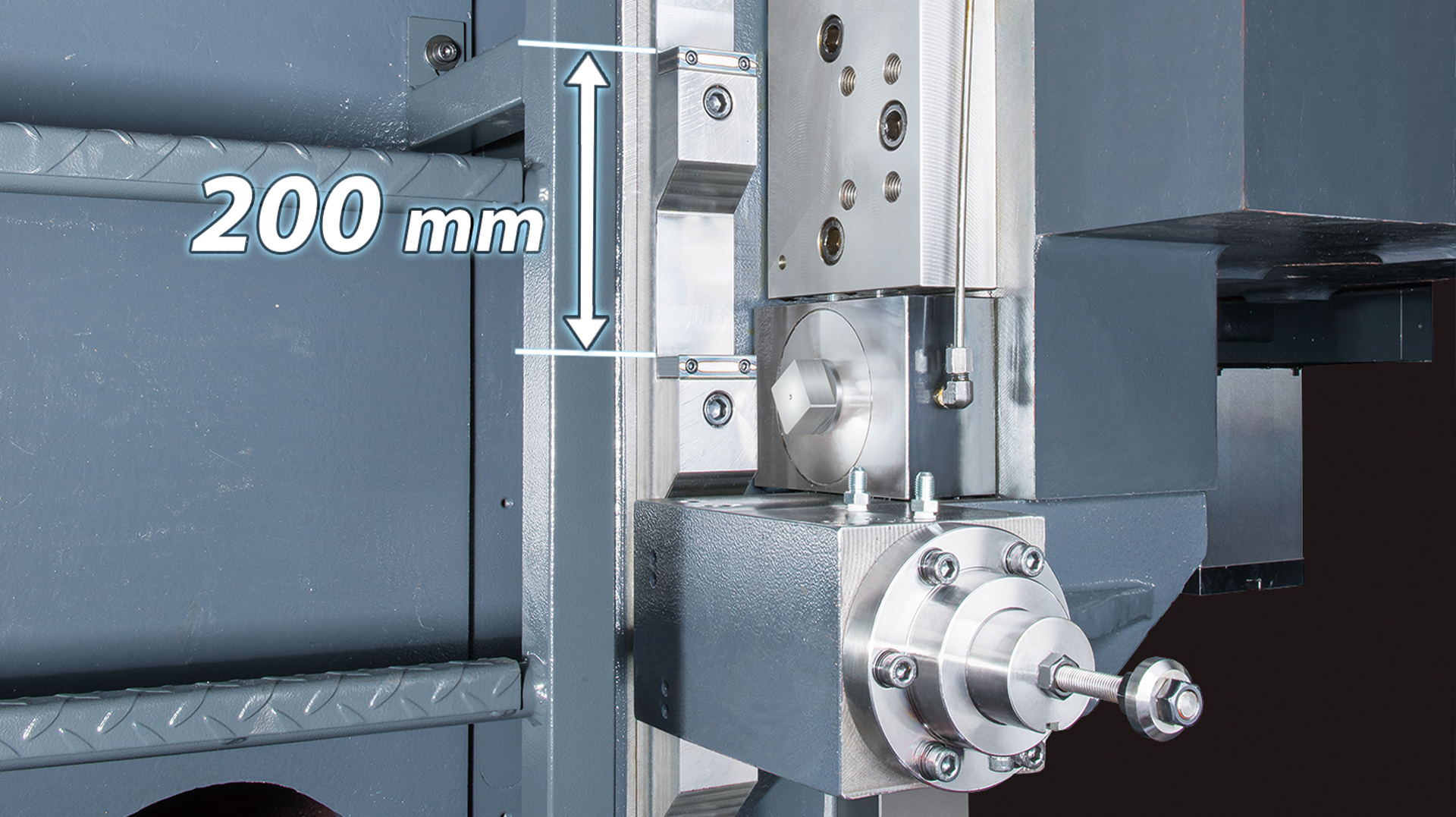

The W-axis features a stepped guideway design

W-axis positioning & clamping mechanism

Tooling spindle

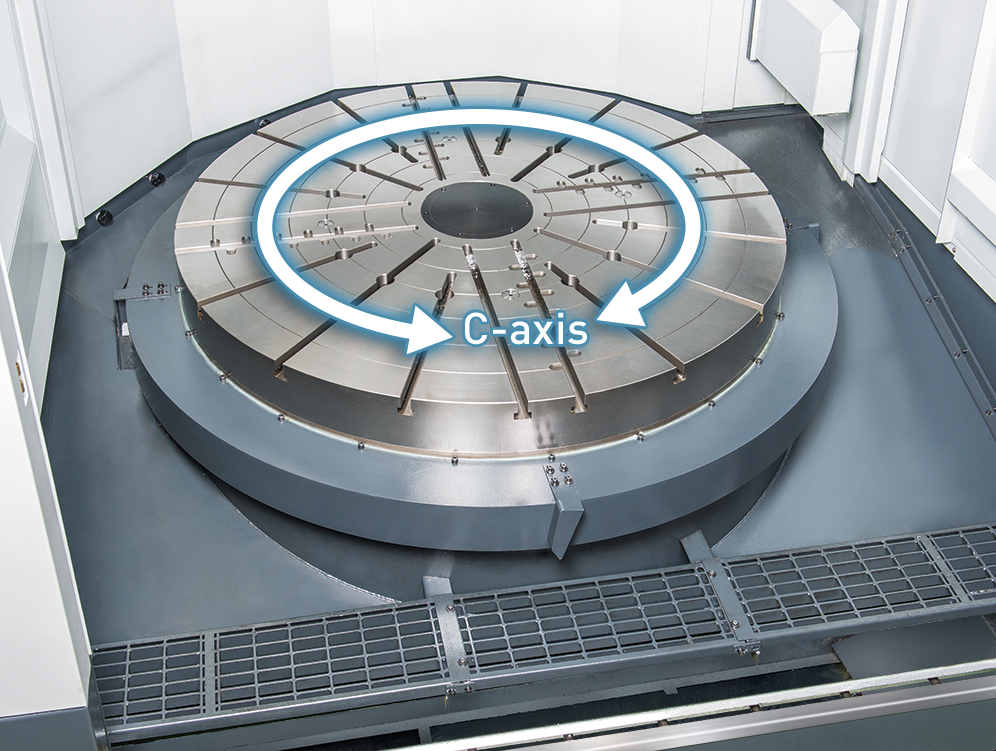

C-axis

Tooling Spindle

- Equipped with NN-type Japanese roller bearings to provide outstanding characteristics such as high rigidity, high precision, and long service life.

- The high reduction ratio 2-speed gear box uses high hardness alloy with forced oil-feed for lubrication and coolant; the gear box can maintain normal operation and low wear even under long hours of low-speed, high-torque working conditions.

C-axis

- The Cf-axis features a high-resolution servo-driven worm gear system that ensures exceptional positioning precision, simplified backlash adjustment, and ultra-fine indexing accuracy of 0.001°.