SW-Ⅱ

On the basis of innovative mechanical structure, plentiful tooling system and flexible hybrid guide bush design, SW-Ⅱ serial can achieve unprecedented rigidity and productivity. SW-Ⅱ with 6 axes ( X / Y / Z / XB / ZB / Y2 ) control ability. Not only complicated work piece can be overcome but also with short cycle time that can satisfy your different processing requirement nowadays and future.

- Structural rigidity increased by 20% compared to the previous generation.

- Optimal production solution for small and medium-diameter workpieces.

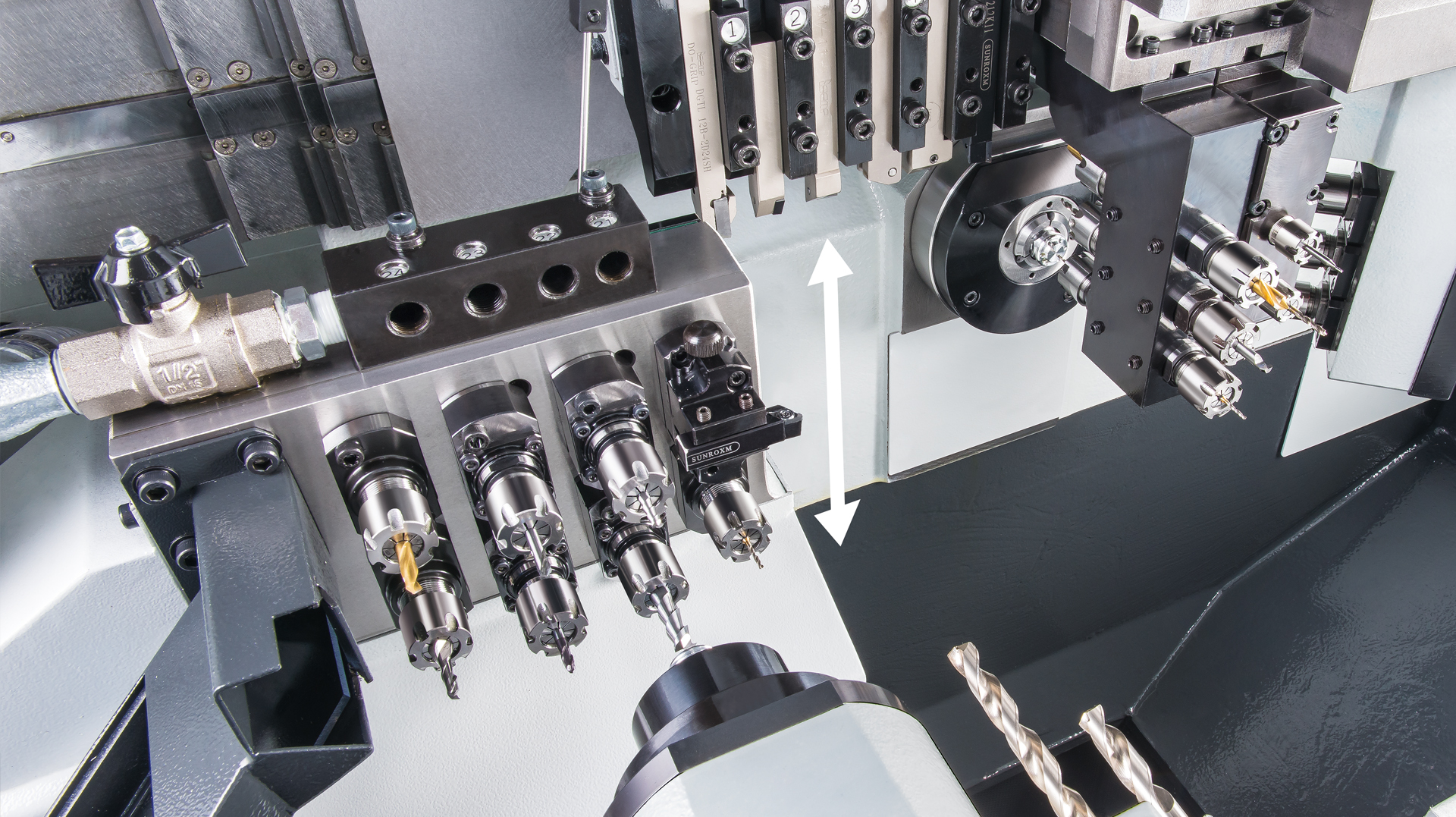

- Designated positions on the side milling live tooling holder can be equipped with 90° live tooling, supporting up to 5 front and 2 back live tools.

- Various live tooling holders such as hobbing, slotting, and thread whirling can be installed as needed.

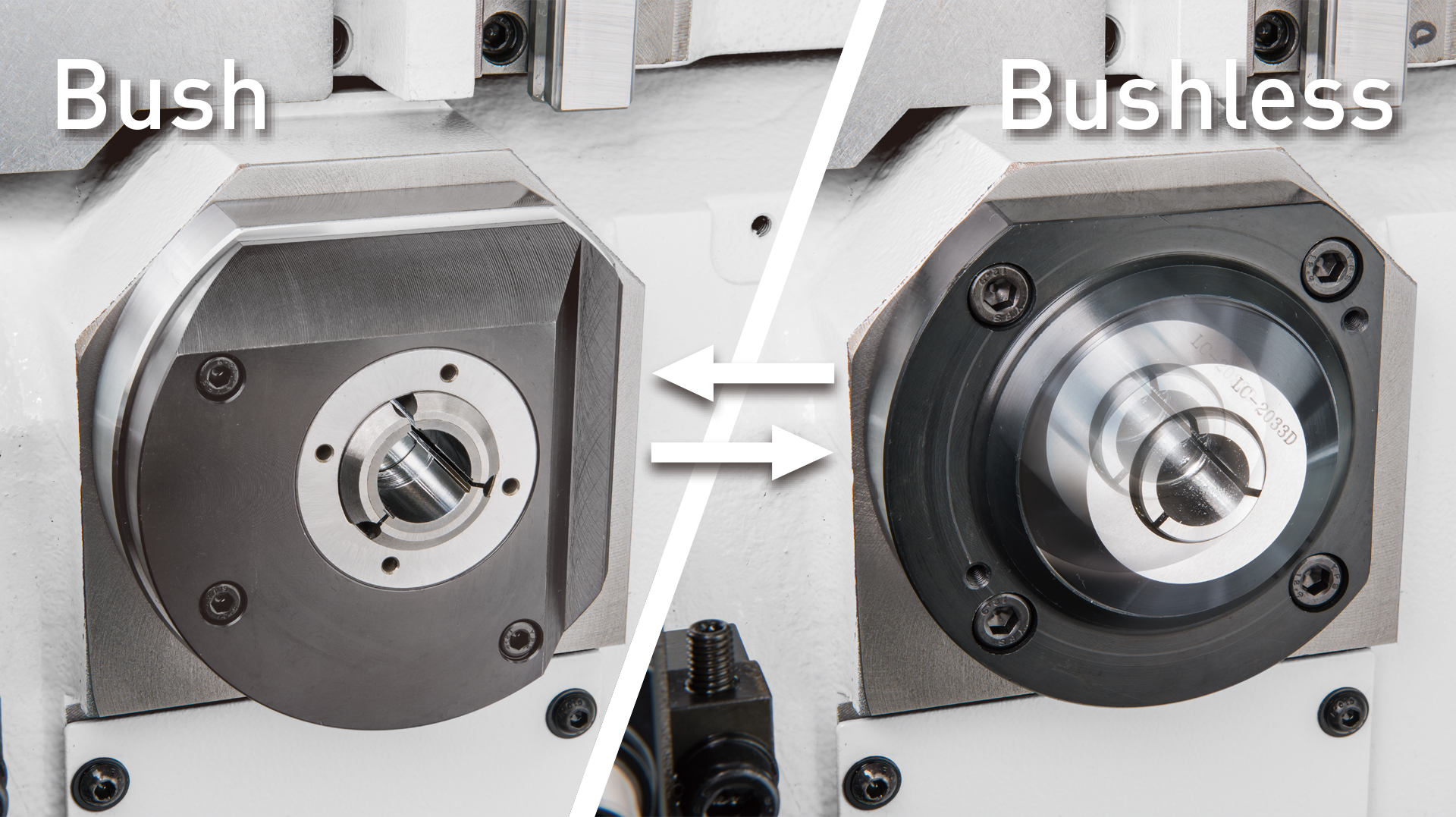

- The hybrid guide bushing design allows switching between guide bush and bushless bushing modes based on production needs.

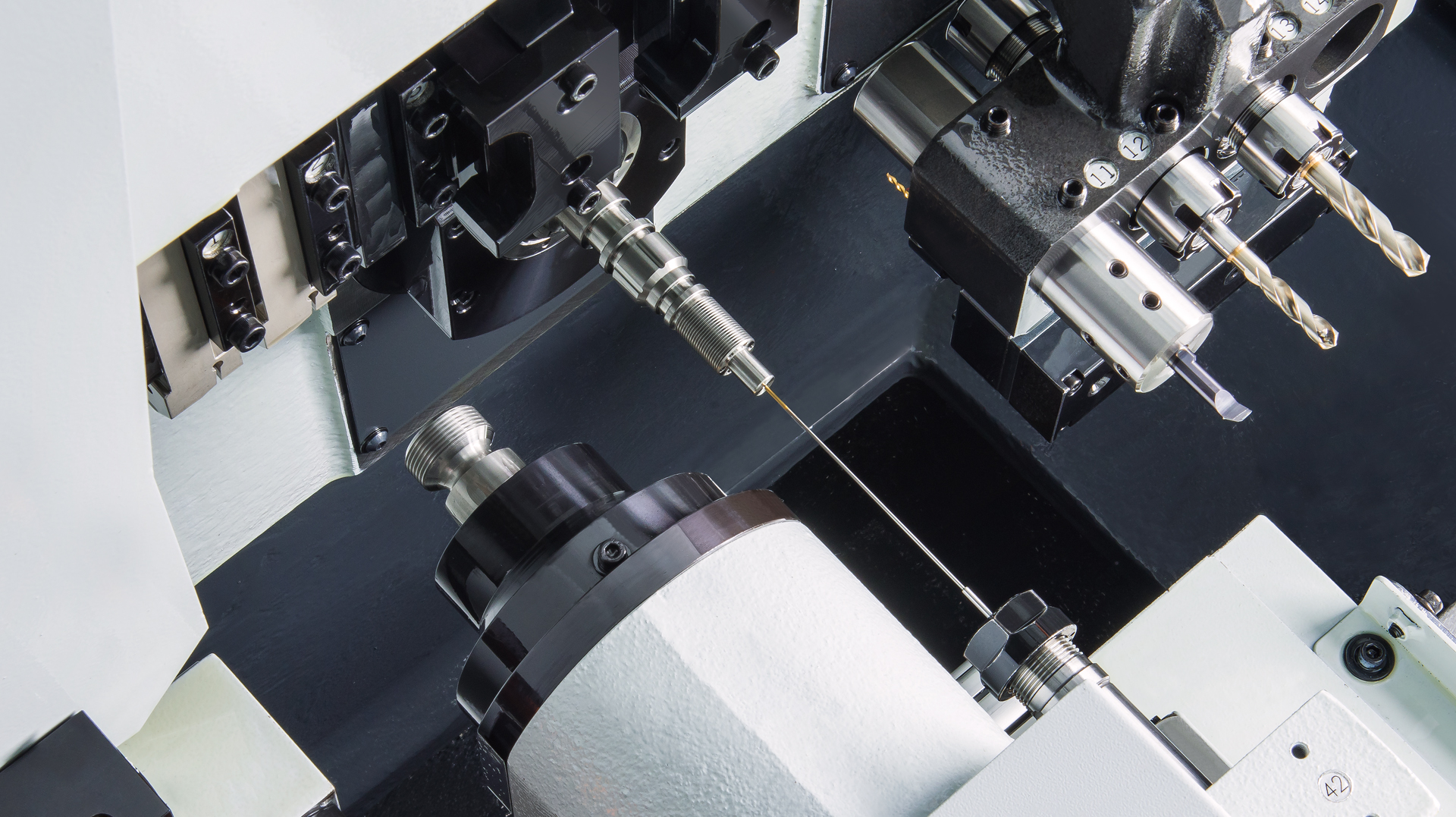

- Y2-axis control function enables off-center drilling, tapping, and milling on the rear-end of workpieces.

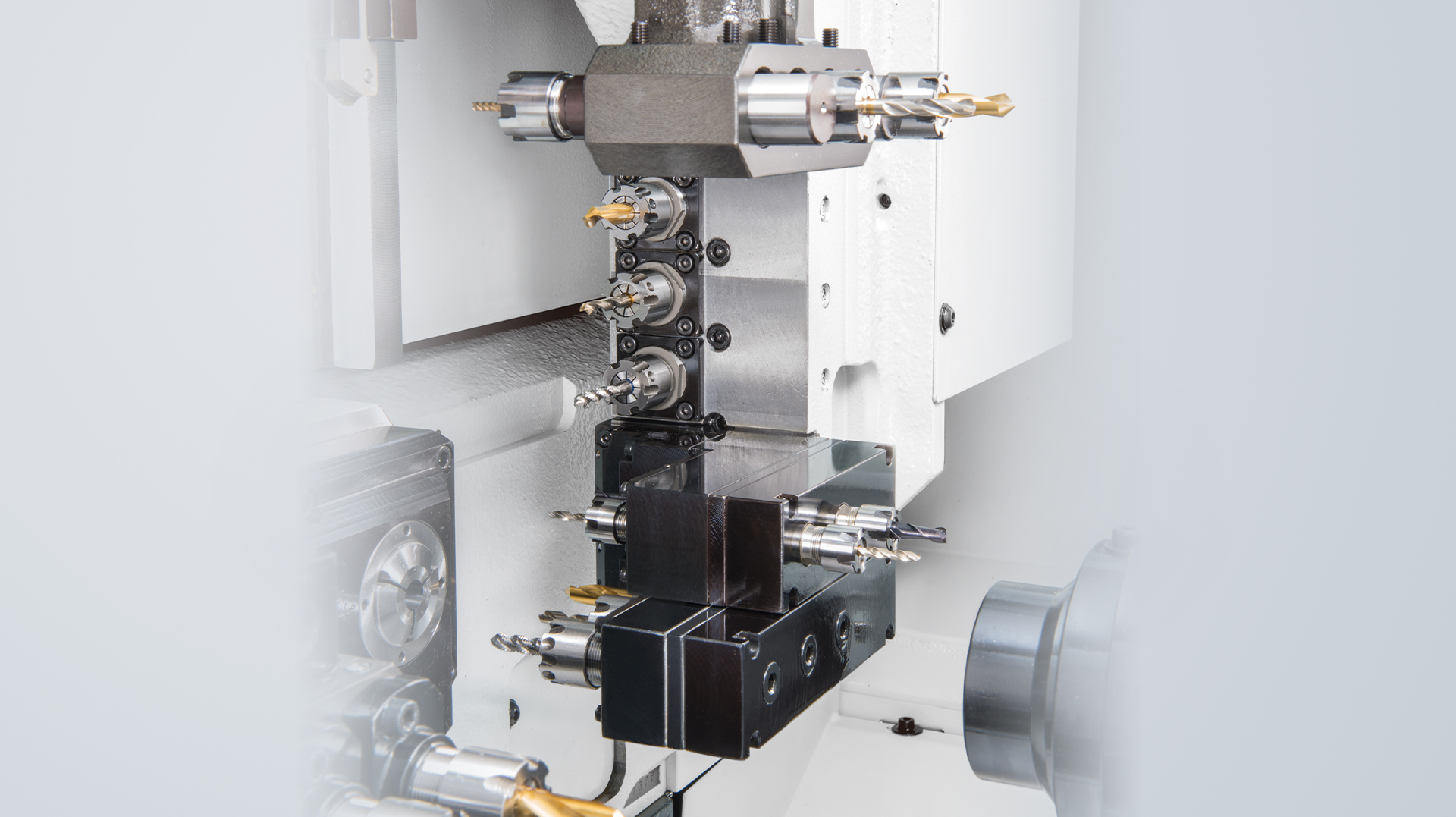

- The sub-spindle body can be equipped with two deep hole drills for deep drilling and tapping operations.

- Standard “Air Bag” function to prevent significant cost losses in case of accidental collisions.

- Optional “OCR Oscillation Cutting” function effectively prevents chip entanglement and improves machine utilization.

Features

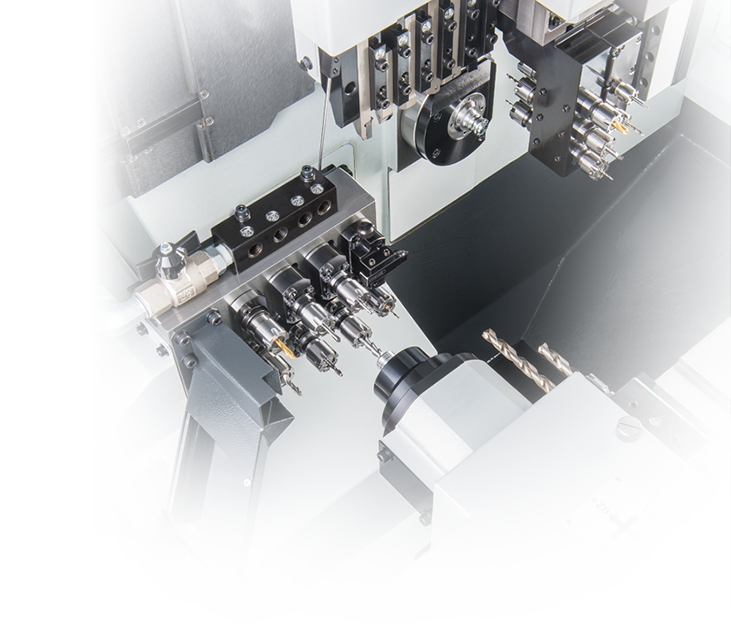

Flexible Tooling System

Comprehensive Machining Capability

Control Functions

Model Variations

A

- Sub-spindle

- Backworking

tooling system - Y2-axis

C

- Sub-spindle

- Backworking

tooling system - Y2-axis

D

- Sub-spindle

- Backworking

tooling system - Y2-axis

Y

- Sub-spindle

- Backworking

tooling system - Y2-axis

Hybrid guide bush

Deep hole drilling

Expansion live tooling

Y2-axis function

Rear-end Machining

- The sub-spindle of the SW-32Ⅱ features a built-in motor design (optional for SW-20Ⅱ), offering high speed and low vibration to meet precision machining requirements. Additionally, the sub-spindle is equipped with air blow and part ejector systems for automatic unloading after machining.

C-axis Control

- Working with the live tooling and 0.001˚ high resolution C-axis enables the machine to perform multiple tasks, such as drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations.

Y2-axis Control Function

- With optional Y2-axis function can proceed eccentric drilling / tapping on back of part and drilling / tapping on radial direction.

- The Y2-axis back working tool post can be equipped with eight live tools, enabling it to handle back-side machining previously done by the bi-directional live tool post. This optimizes process allocation and shortens the machining cycle time.