SW-42

Equipped with the latest machine tool technology and high-quality components, GOODWAY's SW-42 series SWISS type turning centers feature a comprehensive tooling system, high-power spindle motors, hybrid guide bushing design, and full automation interfaces—delivering efficient production for medium-sized workpieces. Widely adopted in automotive, industrial machinery, and medical device industries.

- Preferred equipment of leading European watch manufacturers.

- Optimal production solution for small and medium-diameter workpieces.

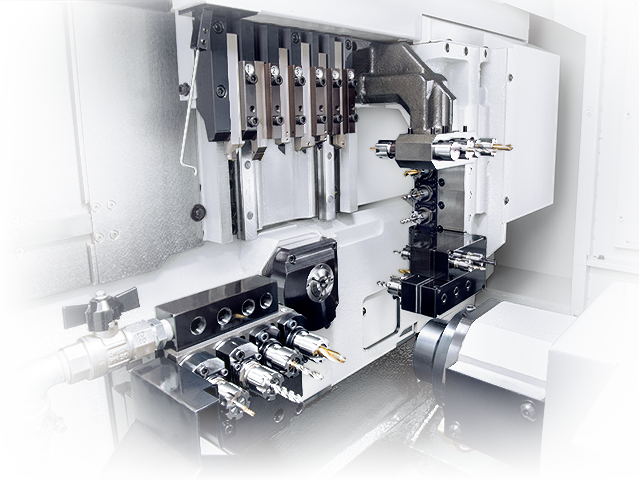

- The complete tooling system enables turning, milling, drilling, and tapping on the front, side, and rear in a single setup.

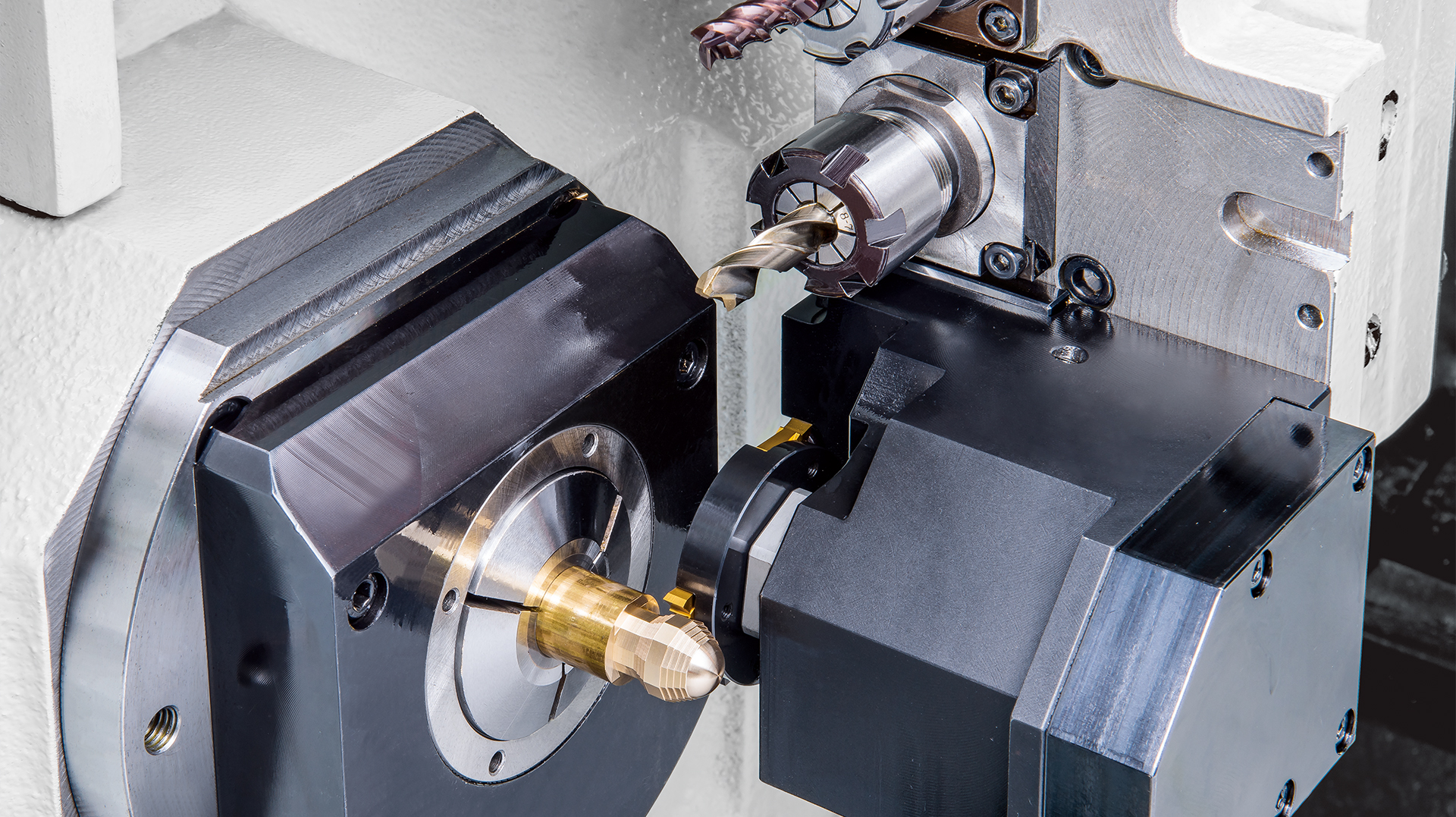

- Various live tooling holders such as hobbing, slotting, and thread whirling can be installed as needed.

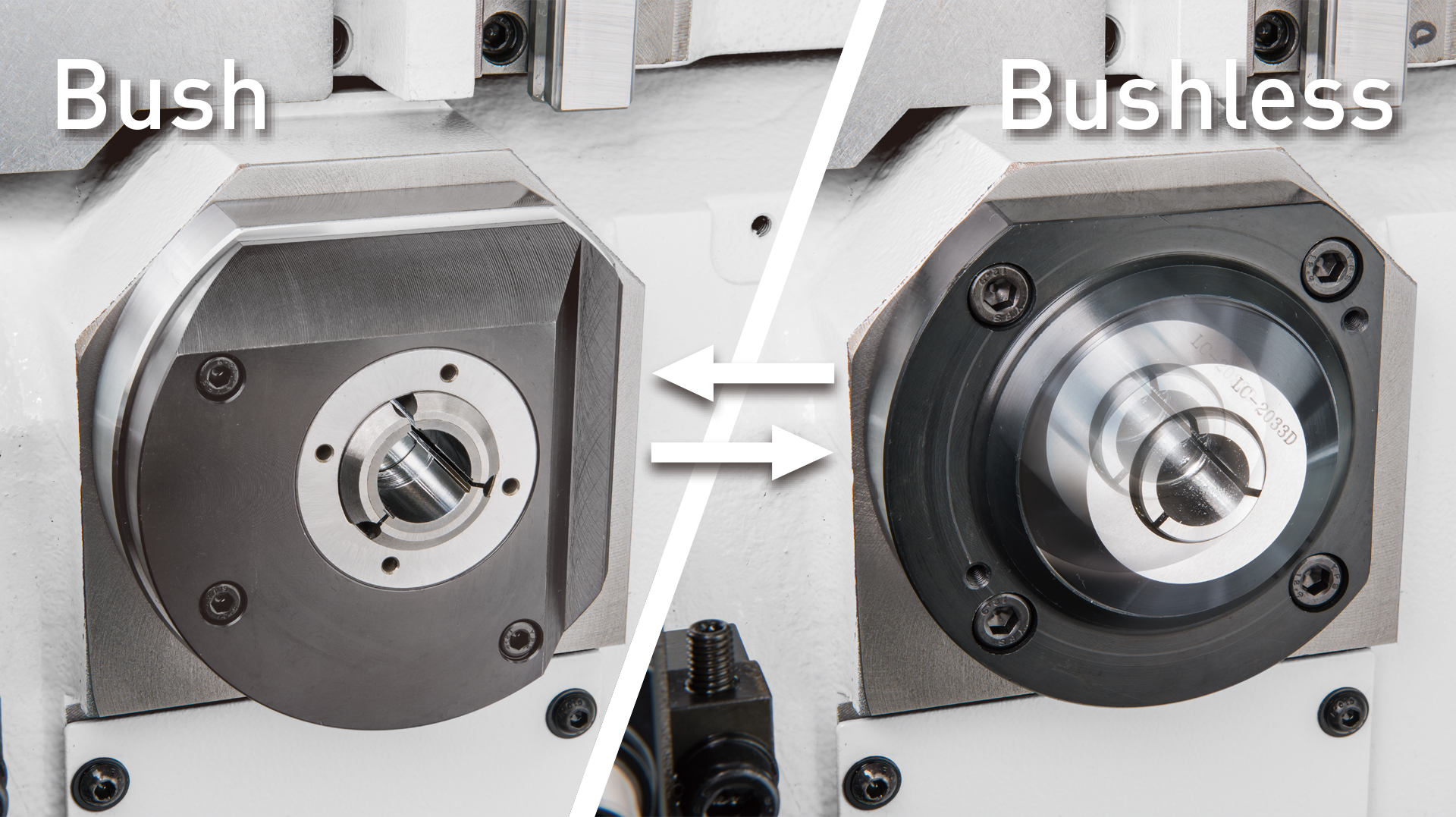

- The hybrid guide bushing design allows switching between guide bush and bushless bushing modes based on production needs.

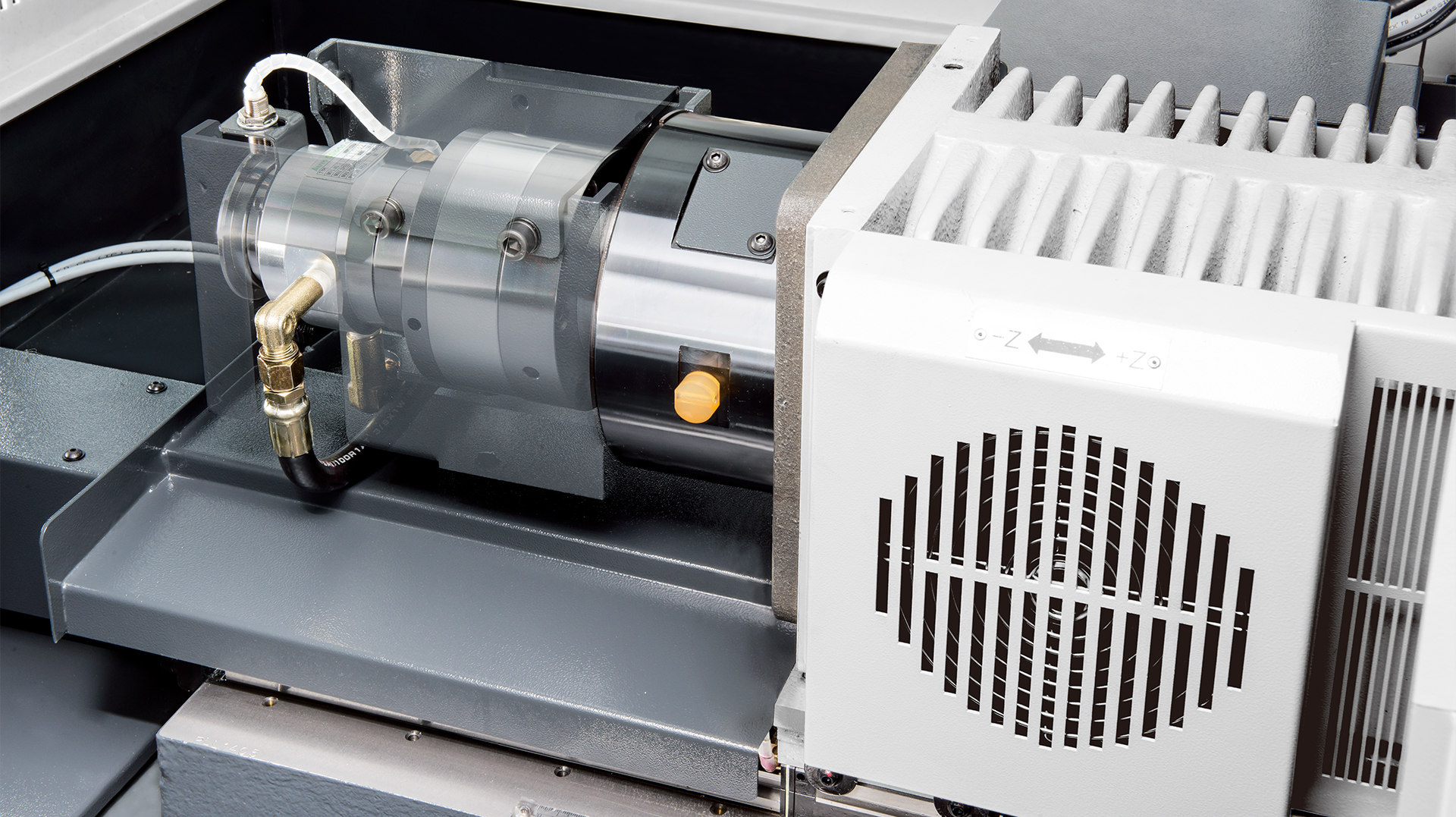

- The clamping mechanism uses rotary hydraulic cylinder drive design, providing ample clamping force to meet the demands of heavy cutting.

- Standard “Air Bag” function to prevent significant cost losses in case of accidental collisions.

- Optional “OCR Oscillation Cutting” function effectively prevents chip entanglement and improves machine utilization.

Features

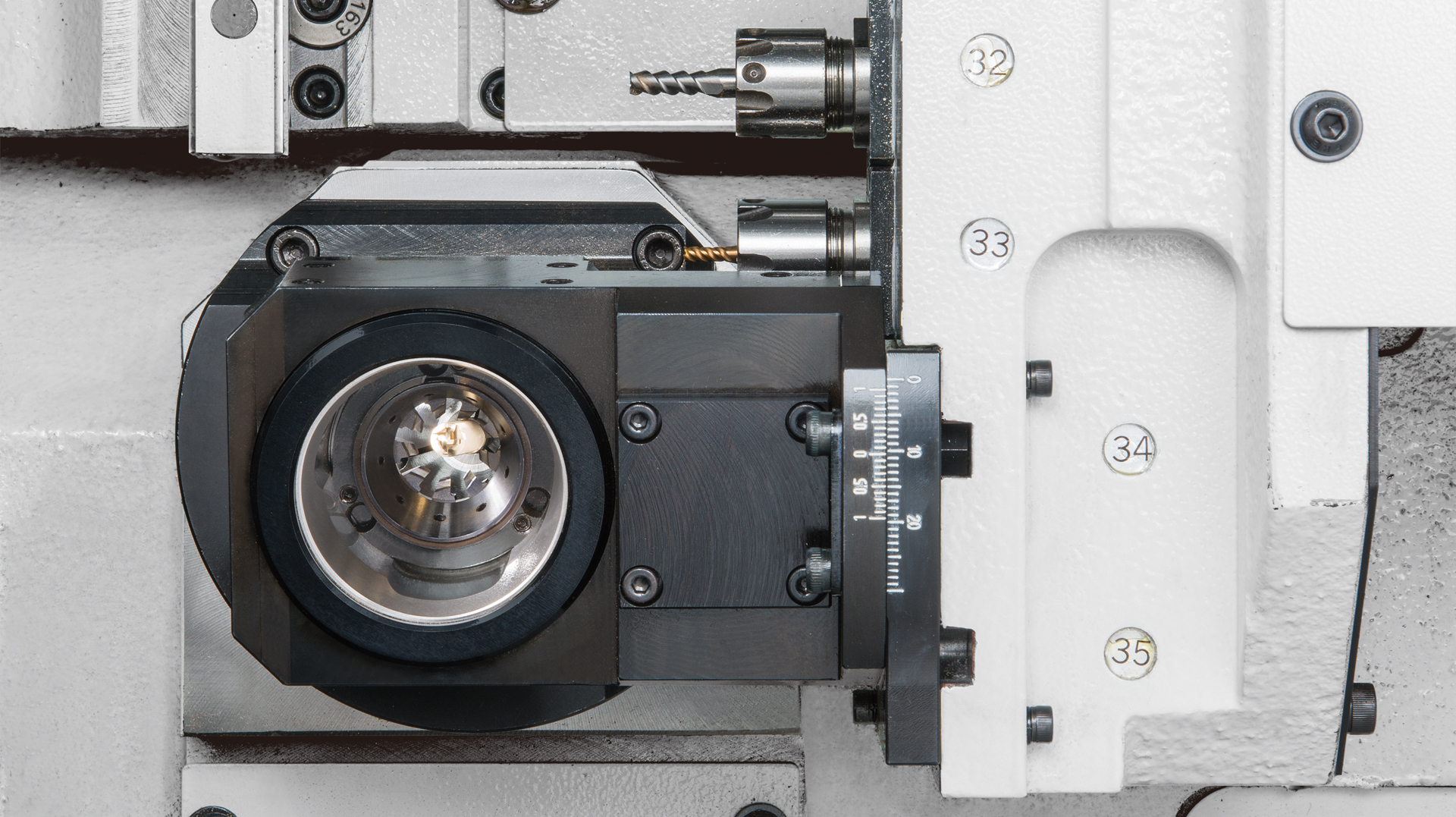

Flexible Tooling System

Comprehensive Machining Capability

Control Functions

Model Variations

A

- Sub-spindle

- Backworking

tooling system

C

- Sub-spindle

- Backworking

tooling system

D

- Sub-spindle

- Backworking

tooling system

Hybrid guide bush

Spindle hydraulic cylinder

Polygon turning

Thread whirling

Rear-end Machining

- The sub-spindle is driven by a high-power 5.5 kW spindle motor, providing sufficient torque for heavy-duty cutting operations. The ZB-axis of the sub-spindle features a high-speed linear guideway design, supporting rapid feed rates of up to 30 m/min.

C-axis Control

- Working with the live tooling and 0.001˚ high resolution C-axis enables the machine to perform multiple tasks, such as drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations.