SW-12

On account of accuracy micro parts processing request, GOODWAY SW-12 ultra-performance SWISS turning center designed concept is based on compact machine size and combine with complete tooling system, hybrid guide bush and rapid feed rate, to provide high speed, high accuracy, complicated processing capability. Bring the best production solution for clock, medical industry.

- Ultra-compact 2.5 m² footprint.

- Specifically developed for precision micro parts.

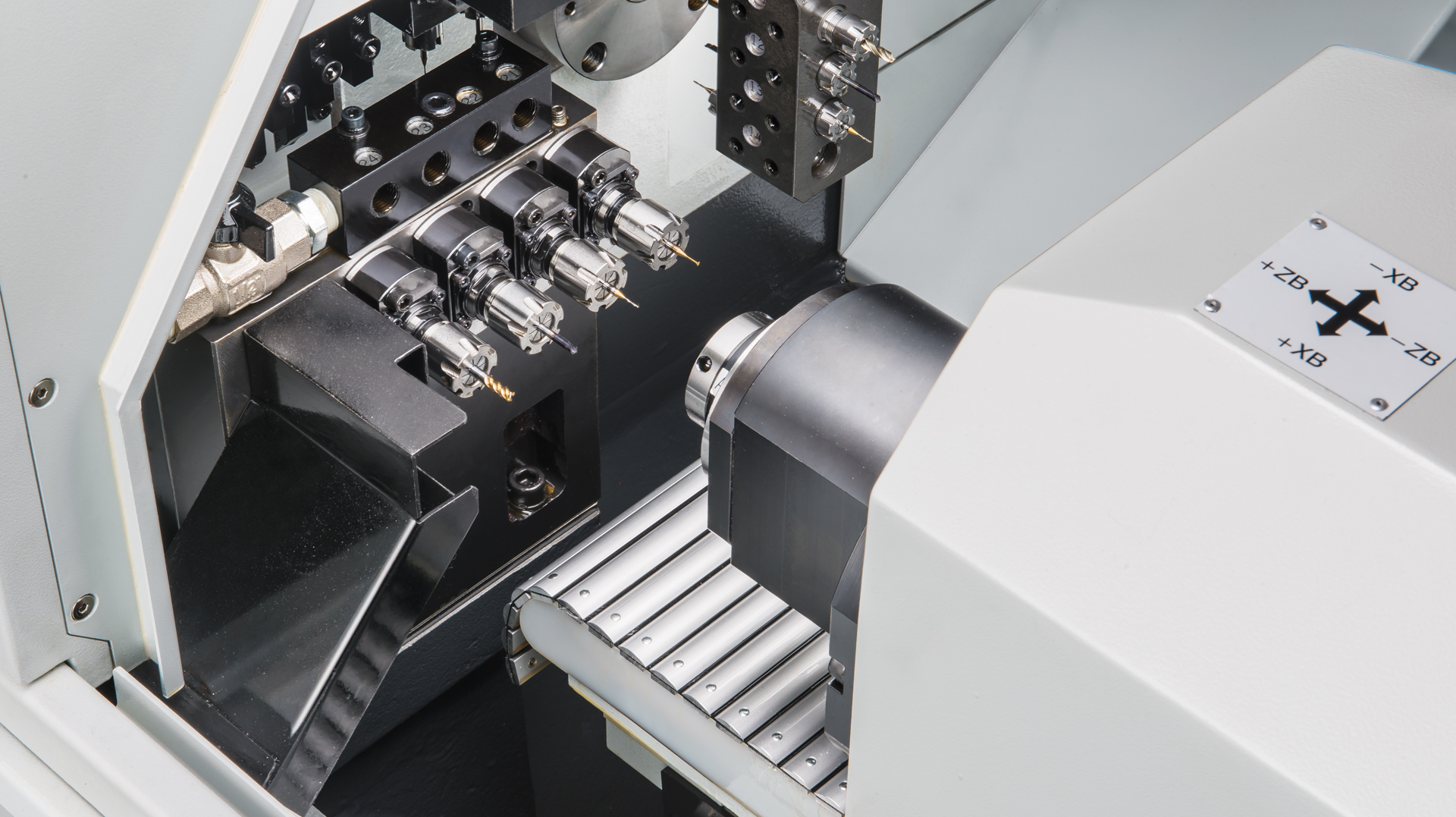

- The live tooling system offers two configurations: standard and expandable (optional).

- The expandable type can be equipped with various interchangeable or special live tool holders as needed.

- Axial rapid feed rate of 32 m/min. enhances tool change efficiency.

- Built-in spindle with a maximum speed of 10,000 rpm.

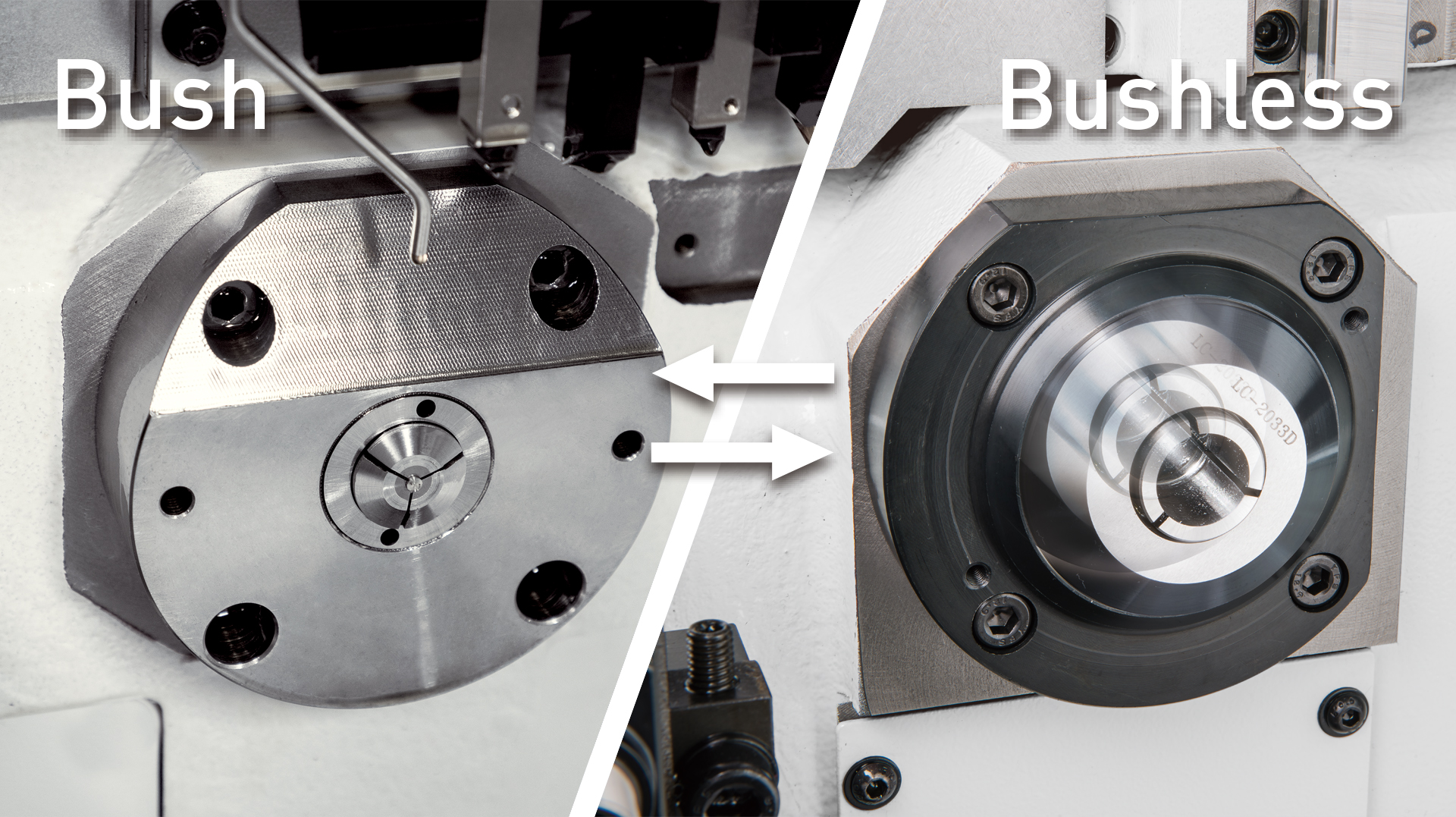

- The hybrid guide bushing design allows switching between guide bush and bushless bushing modes based on production needs.

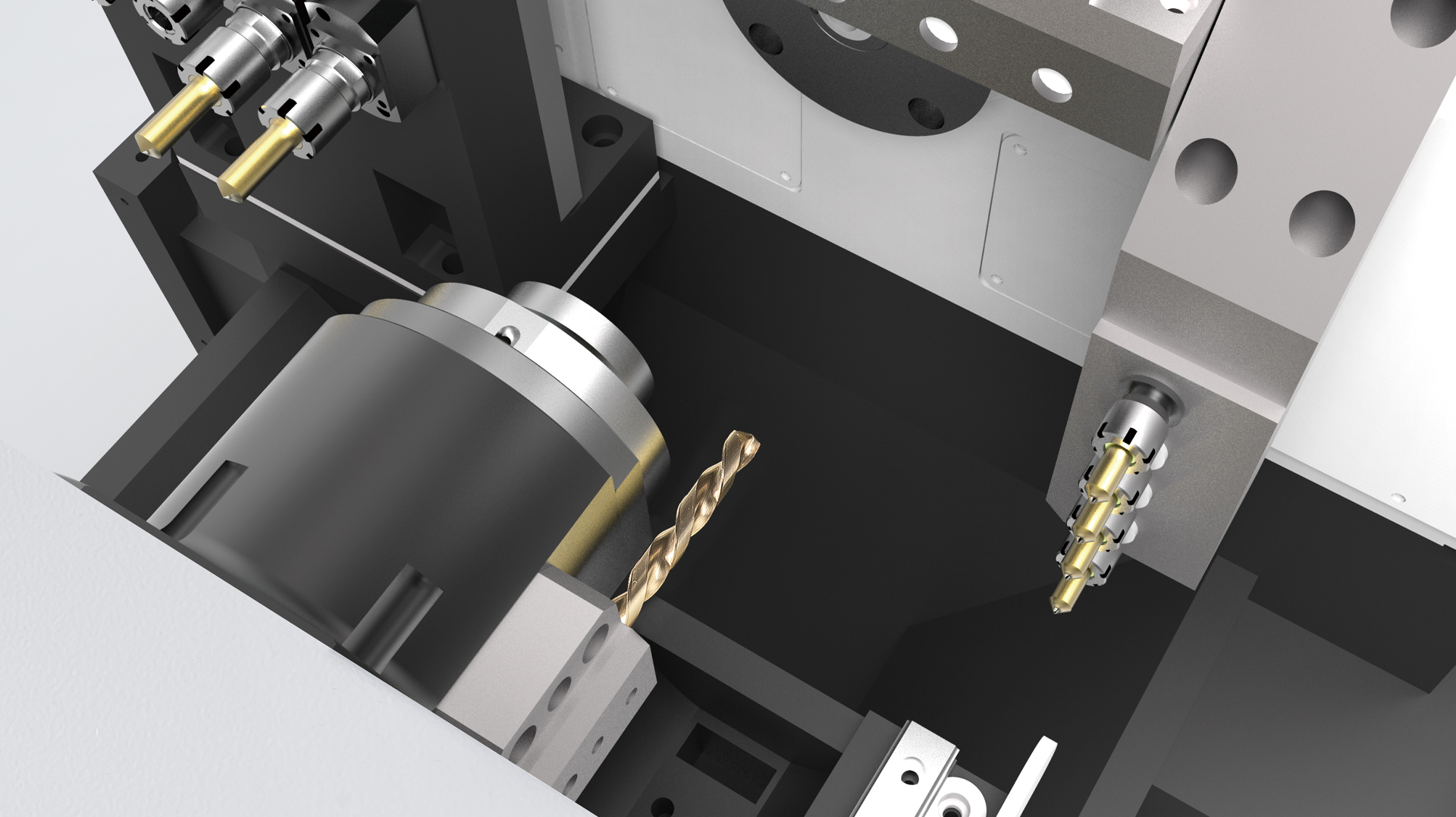

- The sub-spindle body can be equipped with a deep hole drill for deep drilling and tapping operations.

- Standard “Air Bag” function to prevent significant cost losses in case of accidental collisions.

- Optional “OCR Oscillation Cutting” function effectively prevents chip entanglement and improves machine utilization.

Features

Flexible Tooling System

Comprehensive Machining Capability

Control Functions

Model Variations

A

- Sub-spindle

- Backworking

tooling system

C

- Sub-spindle

- Backworking

tooling system

D

- Sub-spindle

- Backworking

tooling system

Hybrid guide bush

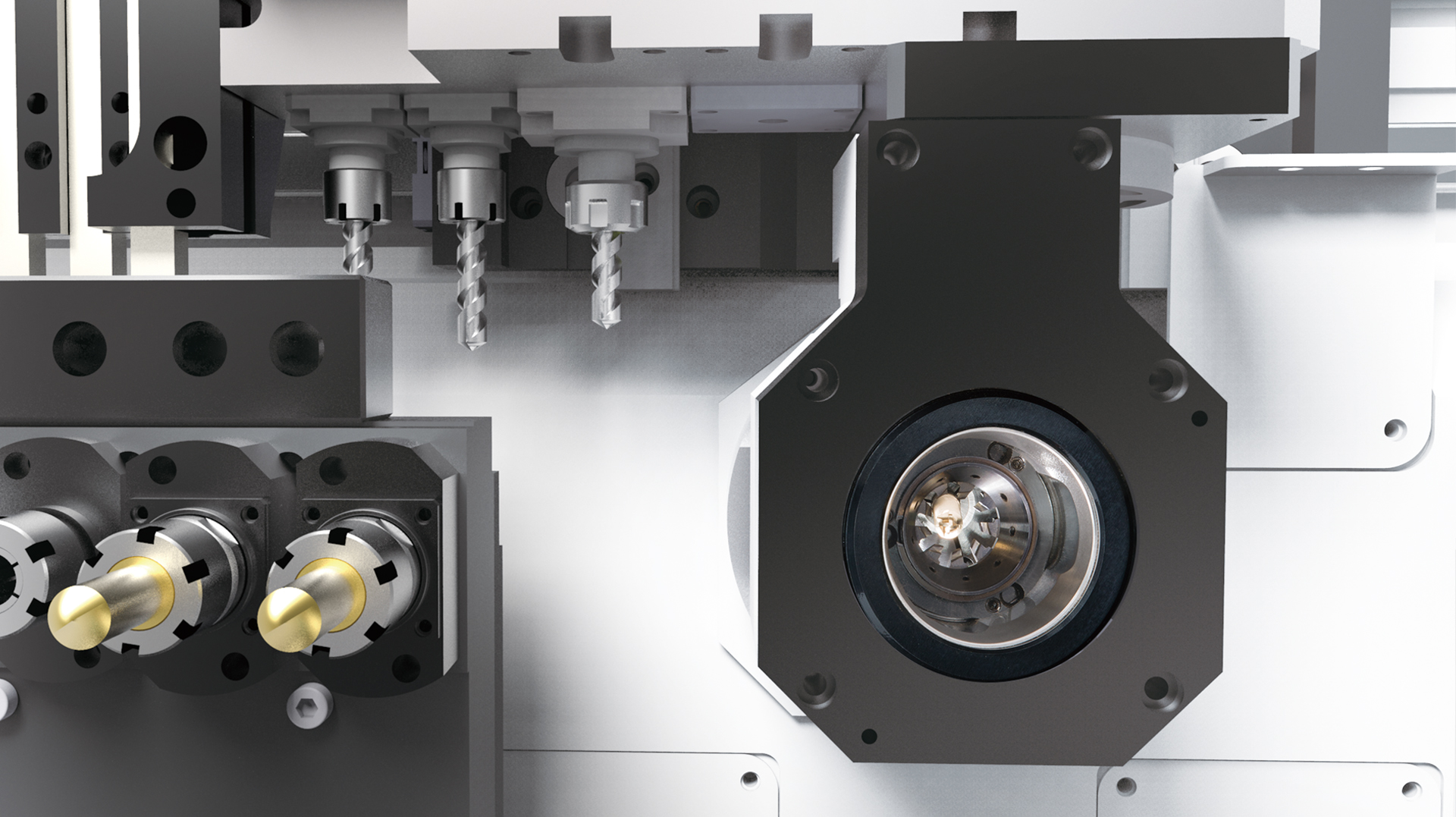

High speed built-in sub-spindle

Deep hole drilling

Thread whirling

Rear-end Machining

- The sub-spindle features a 3.7 kW (15 min.) built-in motor design with a maximum speed of 10,000 rpm, meeting the demands of high-speed, precision cutting.

- Parts clamping by pneumatic system, not only with abundant clamping force, quick movement but also equip with energy saving and many advantages.

C-axis Control

- Working with the live tooling and 0.001˚ high resolution C-axis enables the machine to perform multiple tasks, such as drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations.