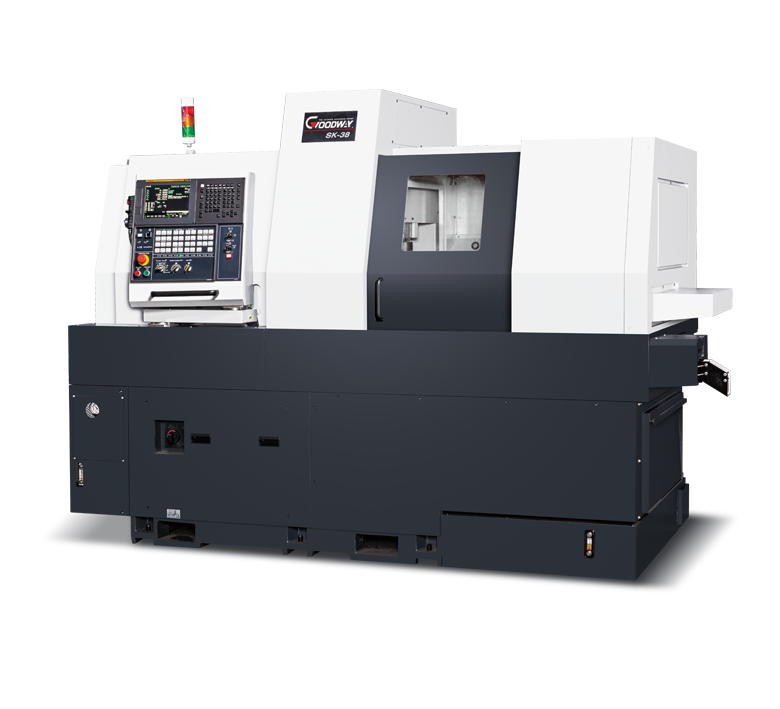

SK-38

Packed with a high-rigidity gantry type tool system structure and powerful Integrated machining functions, GOODWAY SK-38 series offers unprecedented machining capabilities, assisting you in overcoming any mass production demands for large diameters and intricate workpiece patterns.

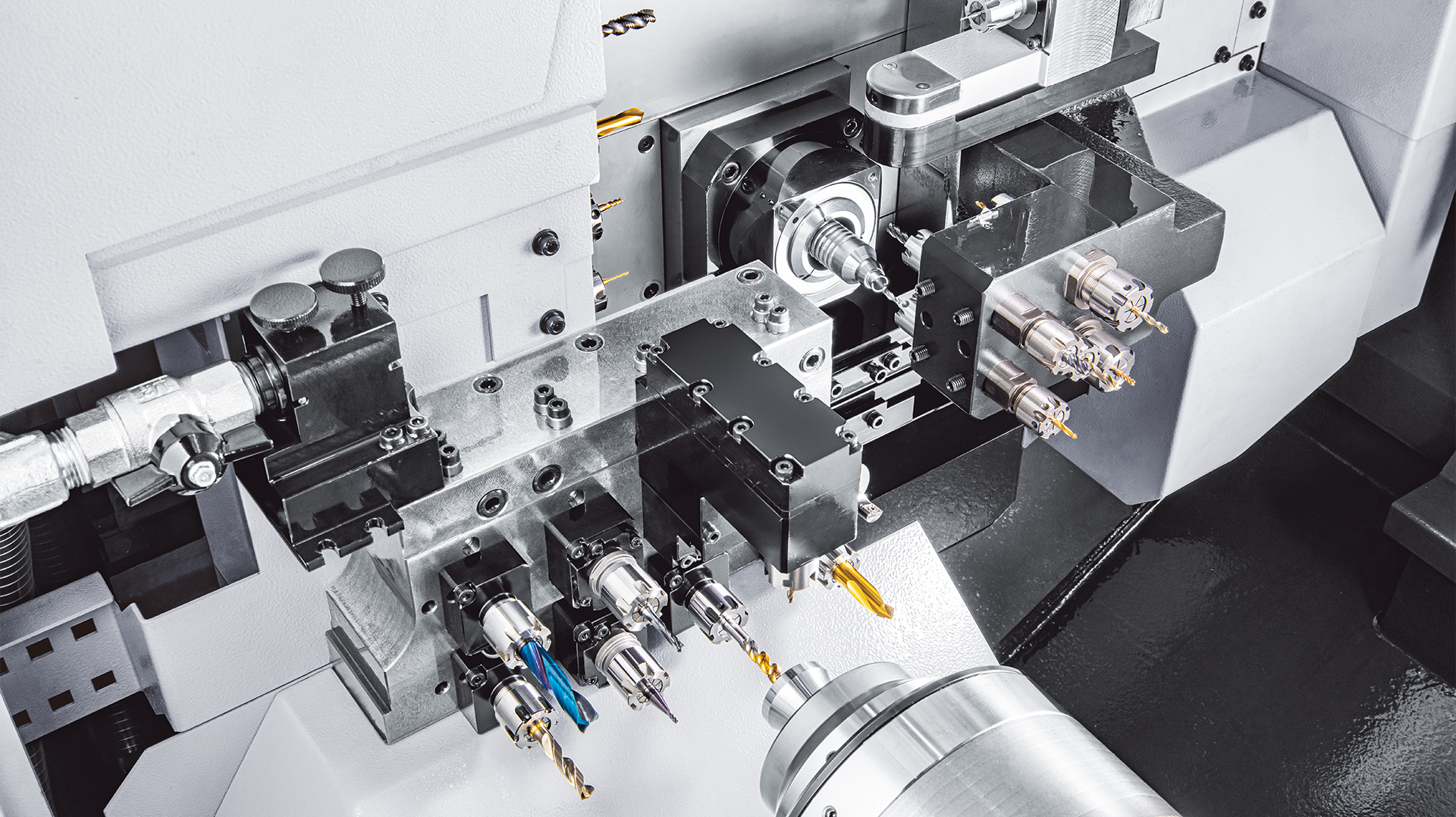

- Ultra high-rigidity gantry type tool system structure.

- Comprehensive machining functions that can easily handle even the most complex workpieces.

- Featuring up to 9 axes control, enabling simultaneous 4 axes machining.

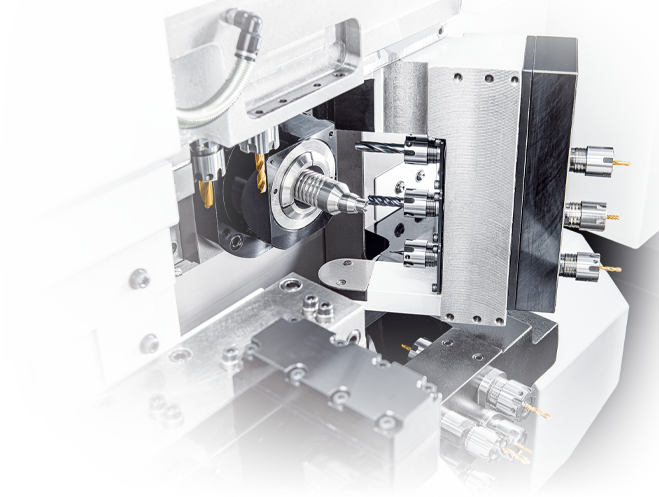

- Designated positions on the side milling live tooling holder can be equipped with 90° live tooling, special live tools, or deep hole drilling.

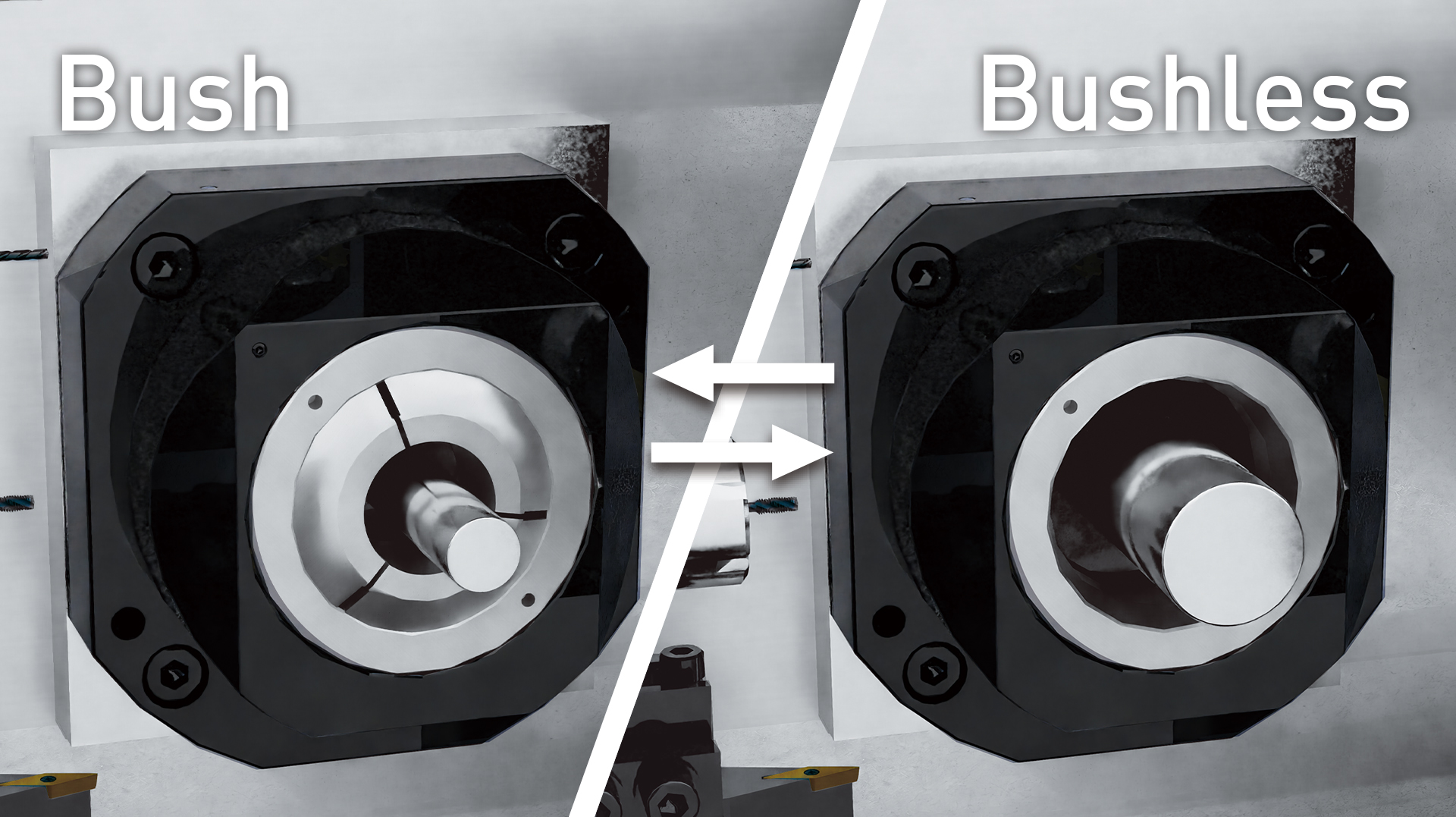

- The hybrid guide bushing design allows switching between guide bush and bushless bushing modes based on production needs.

- The B-axis control enables efficient angled hole machining and 4 axes simultaneous contour milling.

- Y2-axis control function enables off-center drilling, tapping, and milling on the rear-end of workpieces.

- Standard “Air Bag” function to prevent significant cost losses in case of accidental collisions.

- Optional “OCR Oscillation Cutting” function effectively prevents chip entanglement and improves machine utilization.

Features

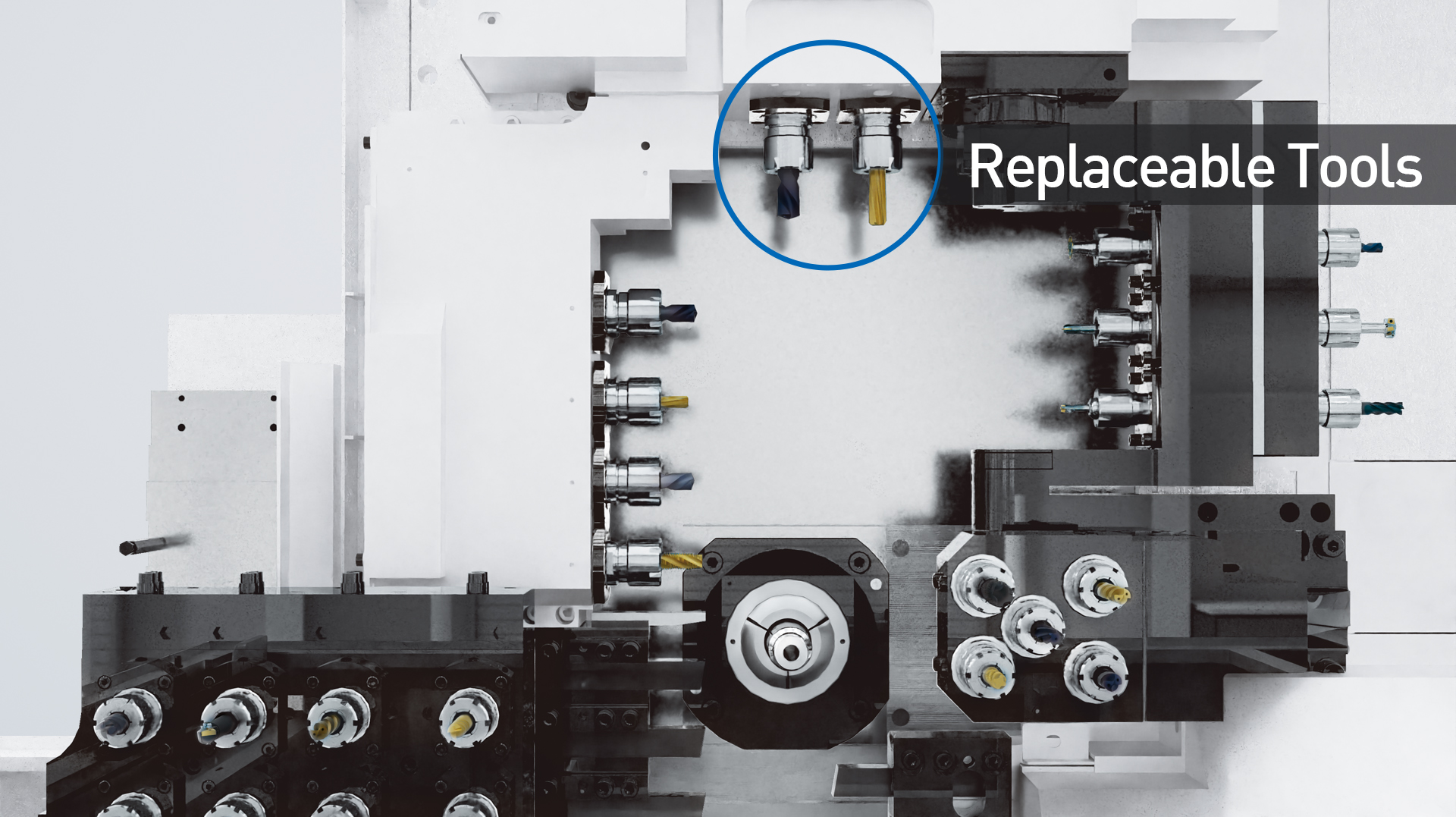

Flexible Tooling System

Comprehensive Machining Capability

Control Functions

Model Variations

A

- Sub-spindle

- Backworking

tooling system - Y2-axis

- B-axis

C

- Sub-spindle

- Backworking

tooling system - Y2-axis

- B-axis

D

- Sub-spindle

- Backworking

tooling system - Y2-axis

- B-axis

Y

- Sub-spindle

- Backworking

tooling system - Y2-axis

- B-axis

B

- Sub-spindle

- Backworking

tooling system - Y2-axis

- B-axis

Flexible tool system

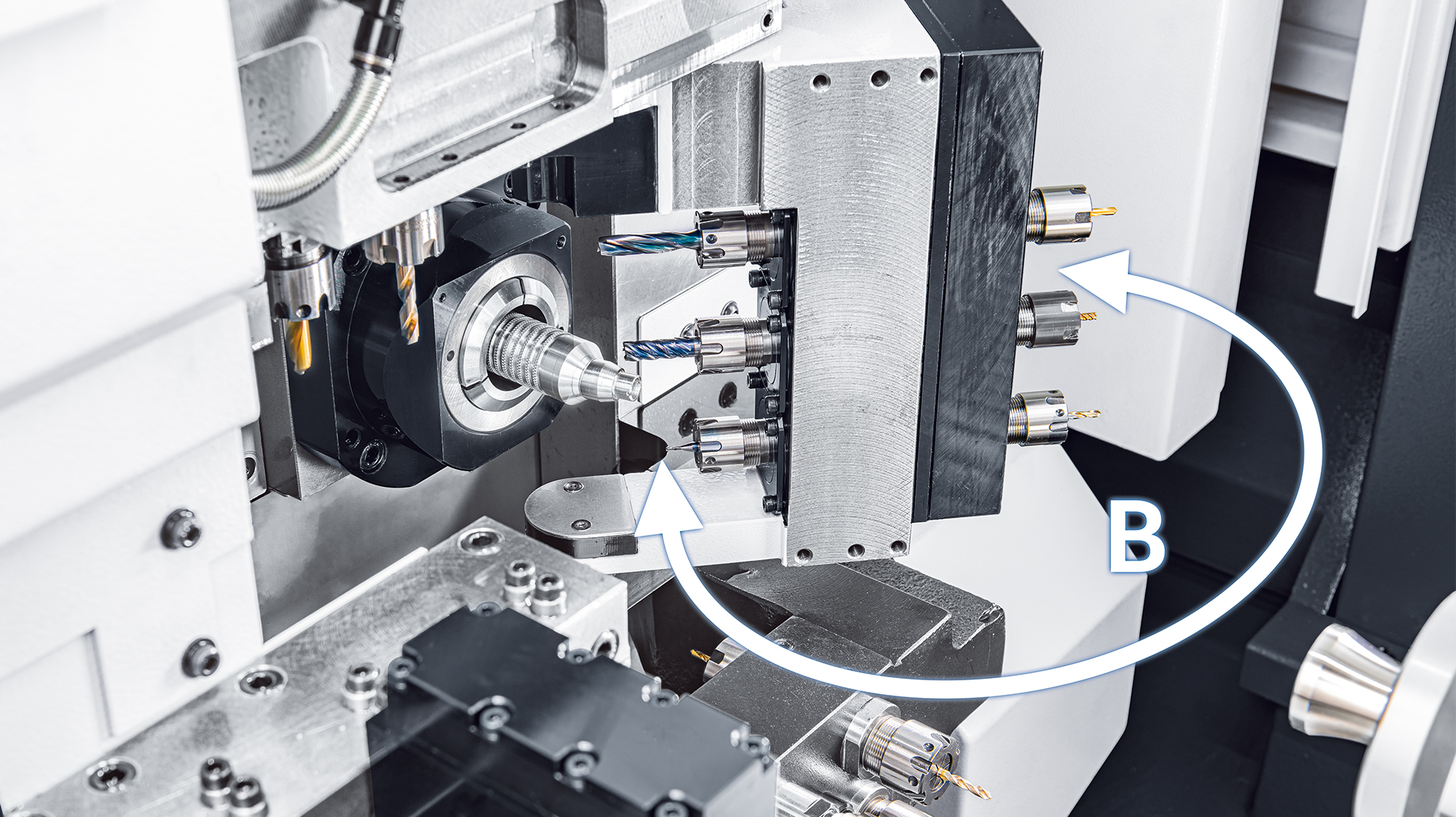

Ultimate B-axis control function

Spindle & sub-spindle simultaneous machining

Hybrid guide bush

B-axis Control Function

- B-axis control capability enables the tool holder to perform milling, drilling, and tapping at specific angles, as well as execute 4 axes simultaneous contour milling.

- The high-resolution angle encoder ensures precise indexing of the B-axis within a range of 135° ( min. indexing increment: 0.001° ).

- Live tooling capacity: 3 (front) / 3 (back)

Y2-axis Control Function

- Y2-axis control function enables off-center drilling, tapping, and milling on the rear-end of workpieces, meeting the machining requirements of various complex-shaped workpieces.

- 69 mm Y2-axis travel design, the back working tool holder can accommodate up to 8 ER16 living tools or be equipped with a 90° live tool holder as needed.

- The live tools are driven by AC servo motor, capable of delivering ample power output with high torque.

C-axis Control

- Working with the live tooling and 0.001˚ high resolution C-axis enables the machine to perform multiple tasks, such as drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations.