GTZ-1500

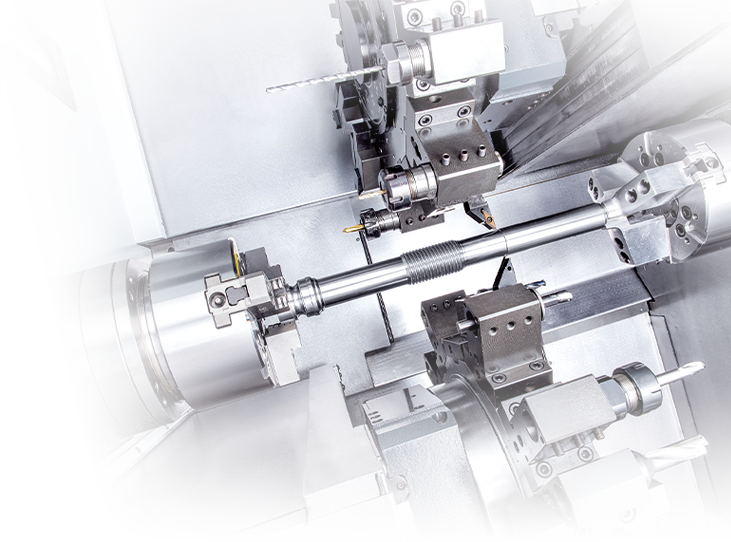

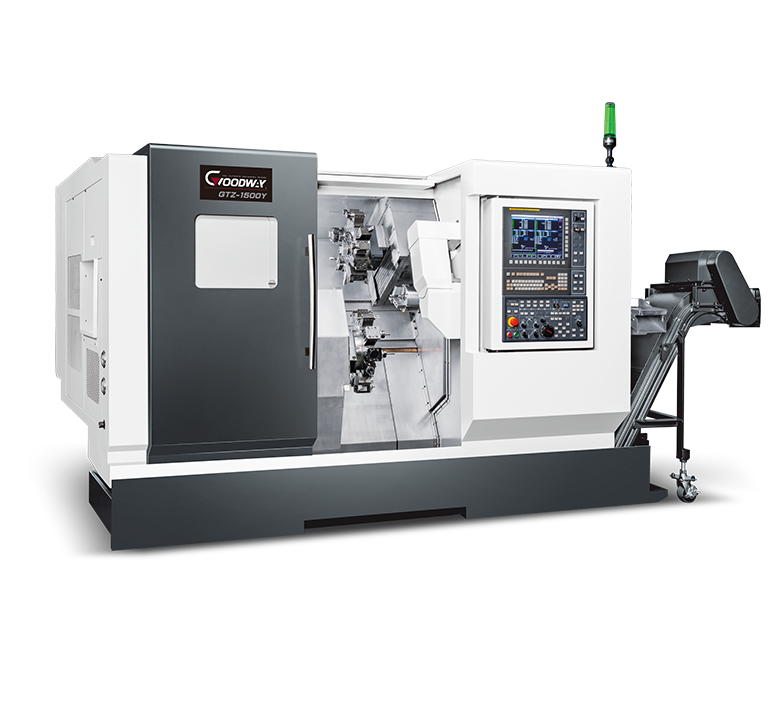

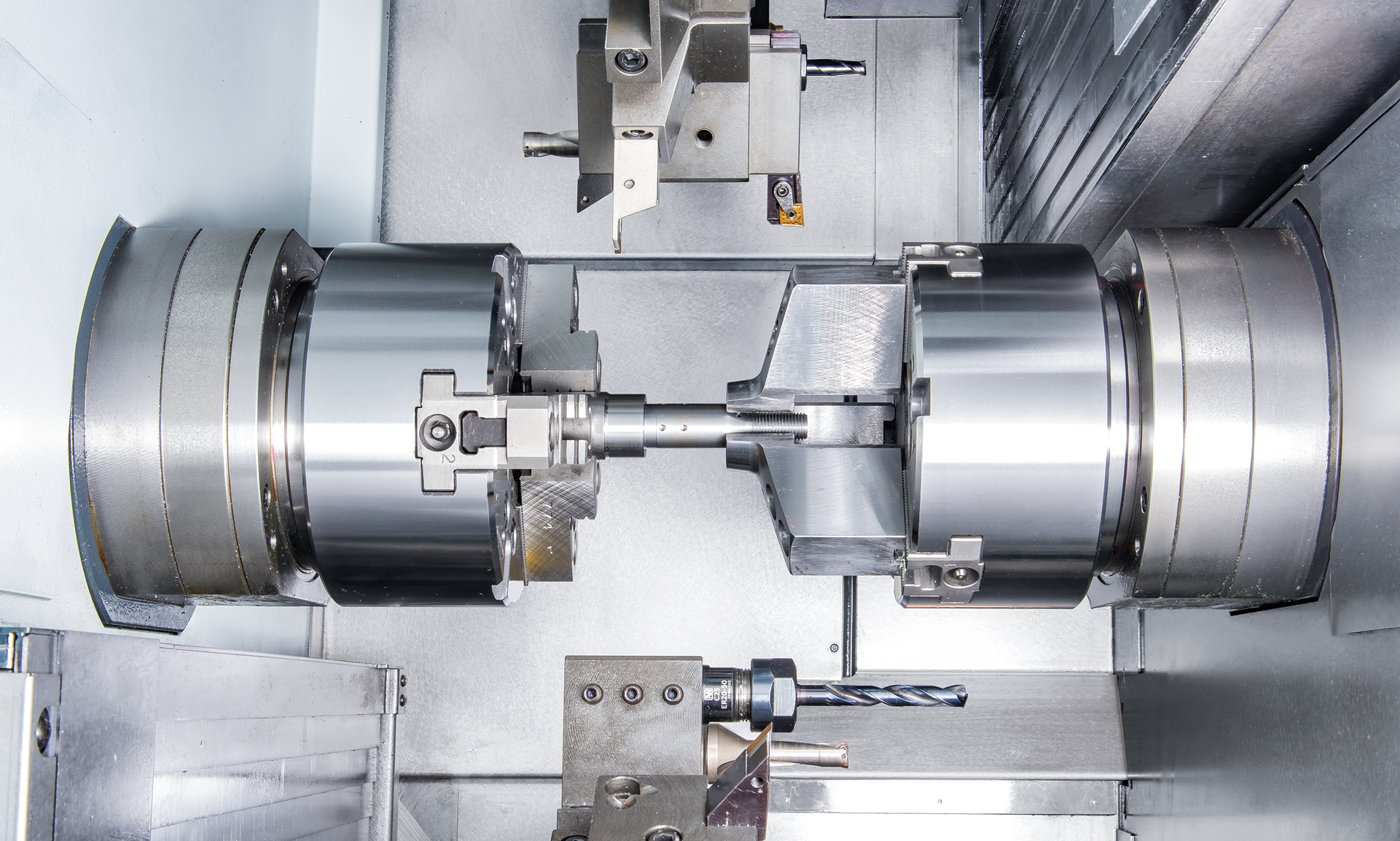

When facing a dilemma of maintaining a highly efficient production while processing extremely complicated machining parts, GOODWAY GTZ-1500 series is your best solution. This model is based on an high rigidity 60° true slant bed, with the advanced structural design of twin spindles, twin Y axes and twin live tooling turrets. Any complex parts can be completed by a GTZ-1500 in a single setup. In addition, this series provides three bar diameters of Ø45 / Ø51 / Ø65 mm, satisfying your processing needs for various workpiece sizes.

- Twin spindles with upper and lower turret design; both turrets can be optionally equipped with Y-axis control function.

- Compact 6.5 m2 footprint with high-efficiency mass production capability.

- Super high rigidity one-piece 60° slant bed structure.

- The axial guideways adopt a high-precision linear guide design, providing excellent controllability and support rigidity.

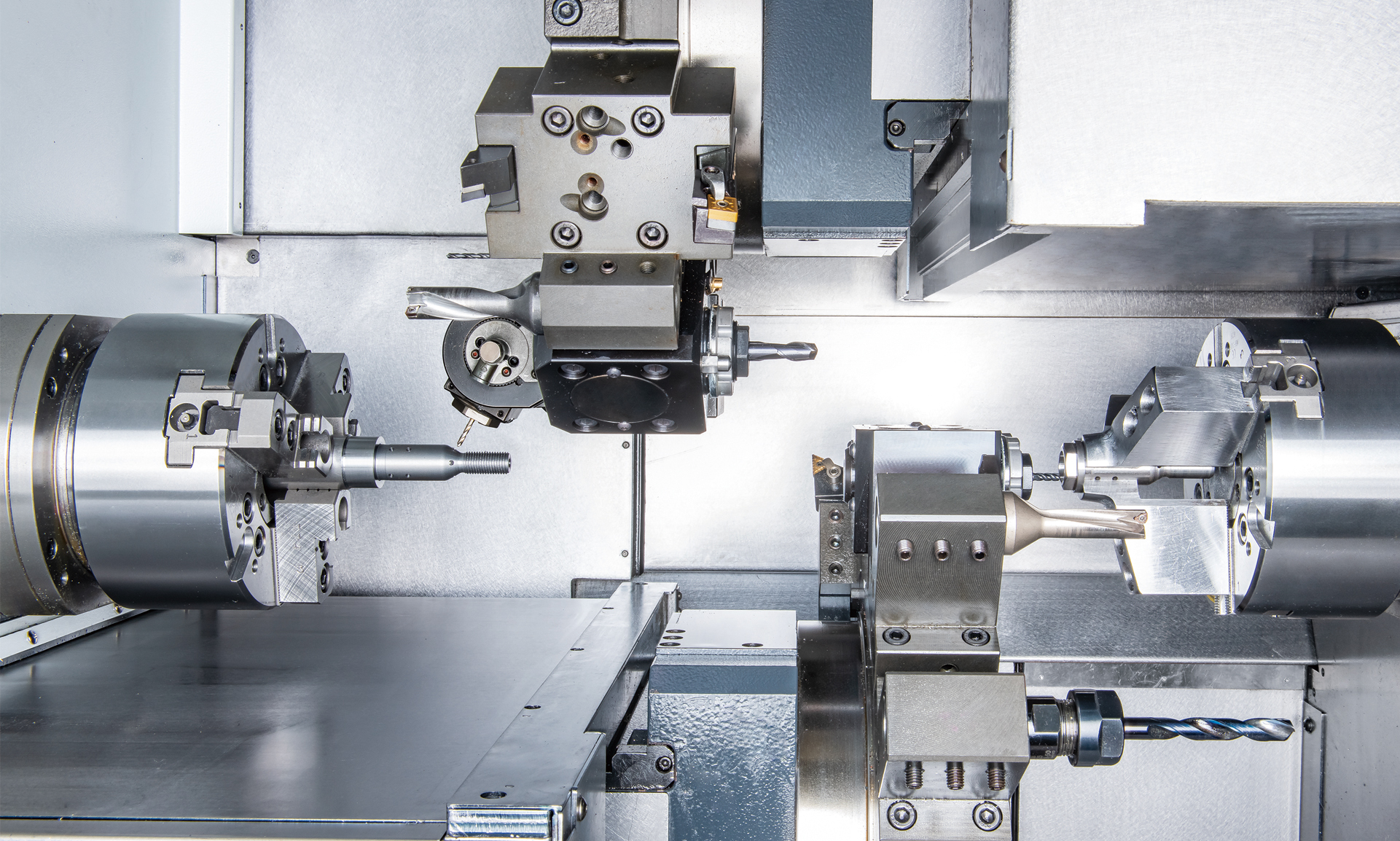

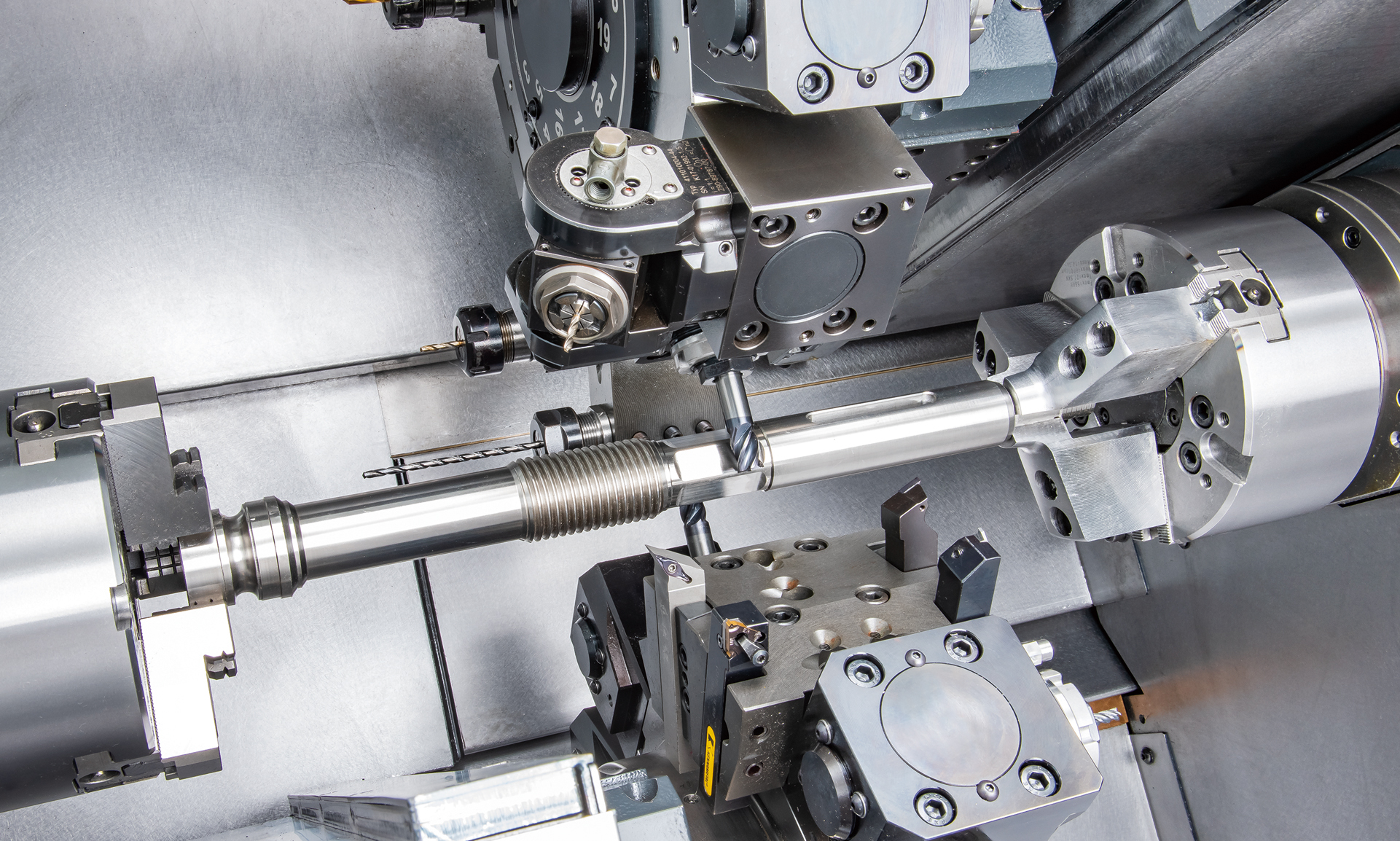

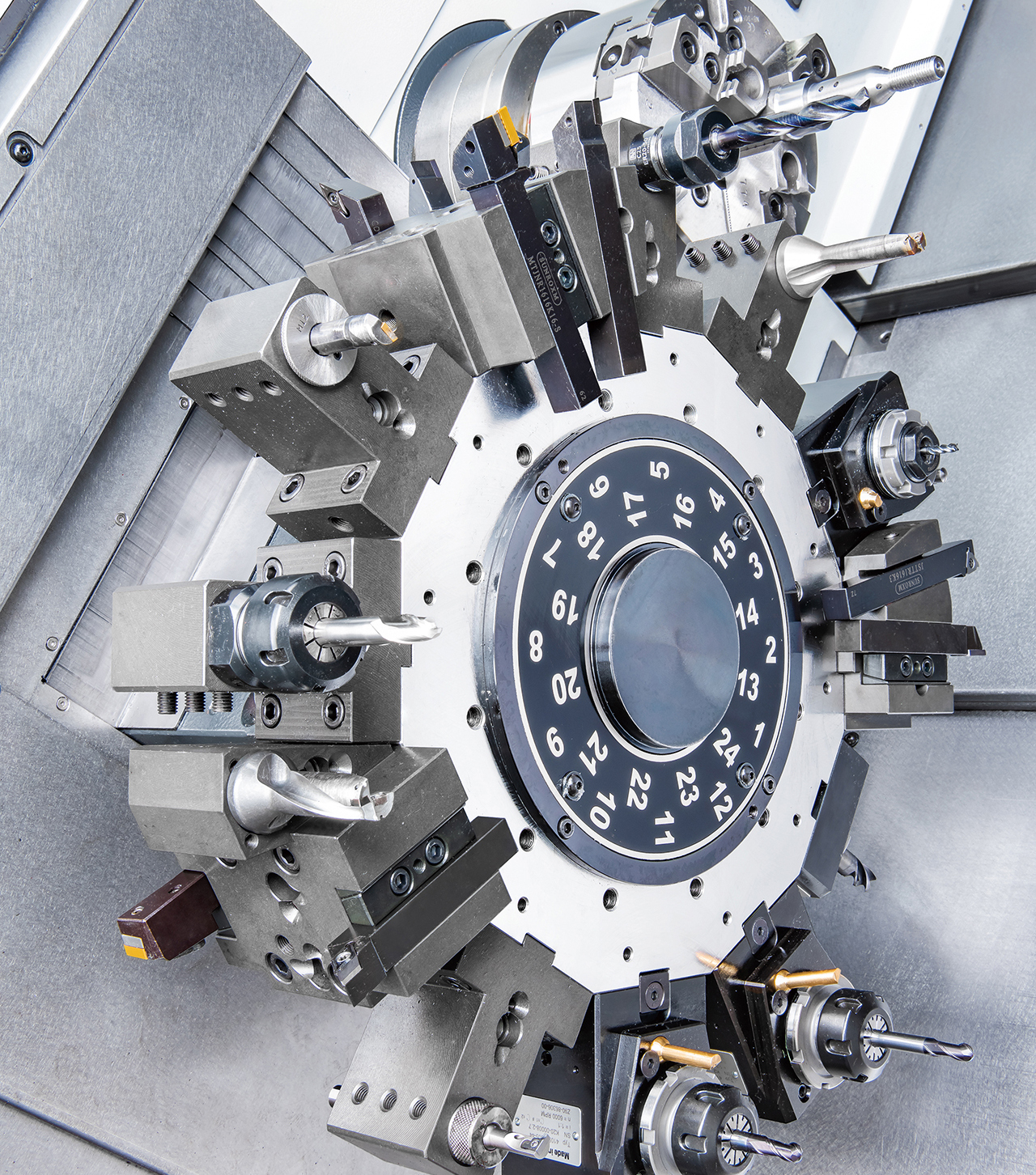

- Turret capacities of 12 or 24 stations allow a single machine to be equipped with up to 48 tools.

- Upper and lower turrets can independently support either the spindle 1 or 2 and are capable of synchronized balanced cutting.

- Spindle 1 & 2 are designed with identical specifications, allowing both front and back machining of the workpiece to be completed on a single GTZ-1500 series.

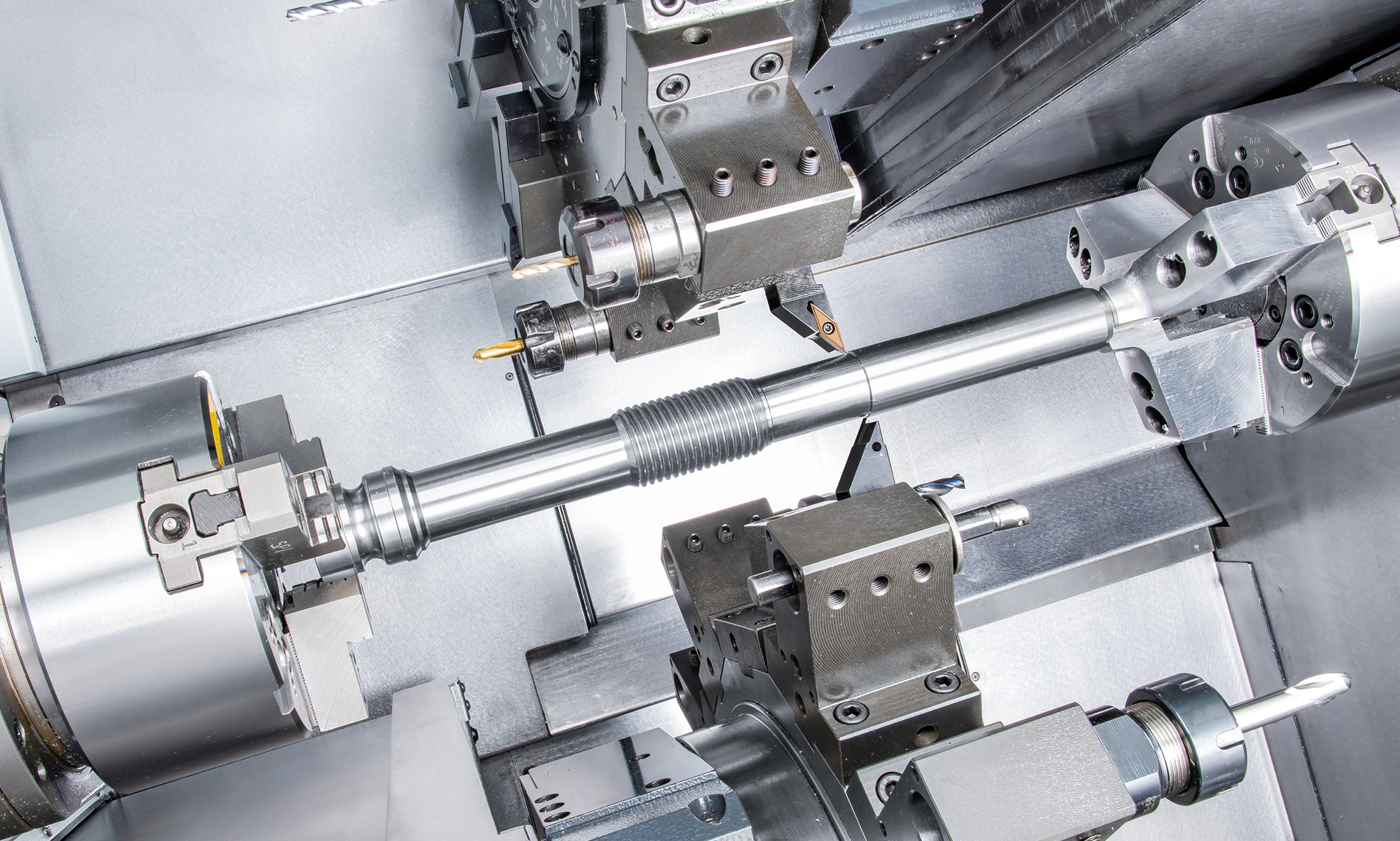

- The spindle offers three specifications for bar capacity, paired with different speed options, with a maximum spindle speed of up to 6,000 rpm ( Ø45 mm ).

- Optional 12- or 24-station live tooling turret (each equipped with 12 live tools), with live tool speeds up to 6,000 / 8,000 rpm.

- Optional Y-axis control enables machining of complex workpieces, with Y1 / Y2-axis stroke of ±42 mm / ±33 mm.

Features

High Rigidity Structure

Tooling System

Powerful Cutting Capability

Integrated Machining Functions

Model Variations

Y

- Live tooling turret

- C-axis

- Y-axis

Upper turret works on spindle 1

Lower turret works on spindle 2

Lower turret works on spindle 2

Synchronic balanced cutting on the work piece from upper and lower turrets

Twin spindles simultaneous part catching

Y-axis simultaneous processing

Live tooling turret

C-axis

Live Tooling Turret

- All series live tooling turret are designed and manufactured by GOODWAY.

- 12 or 24 stations turret are available to meet any needs.

- High speed servo indexing turret technology, achieving 0.2 second indexing for adjacent stations.

- Ultra-high precise curvic couplings accurately position the turret disk.

- Various GOODWAY live tooling holders are available to tackle any challenging machining tasks.

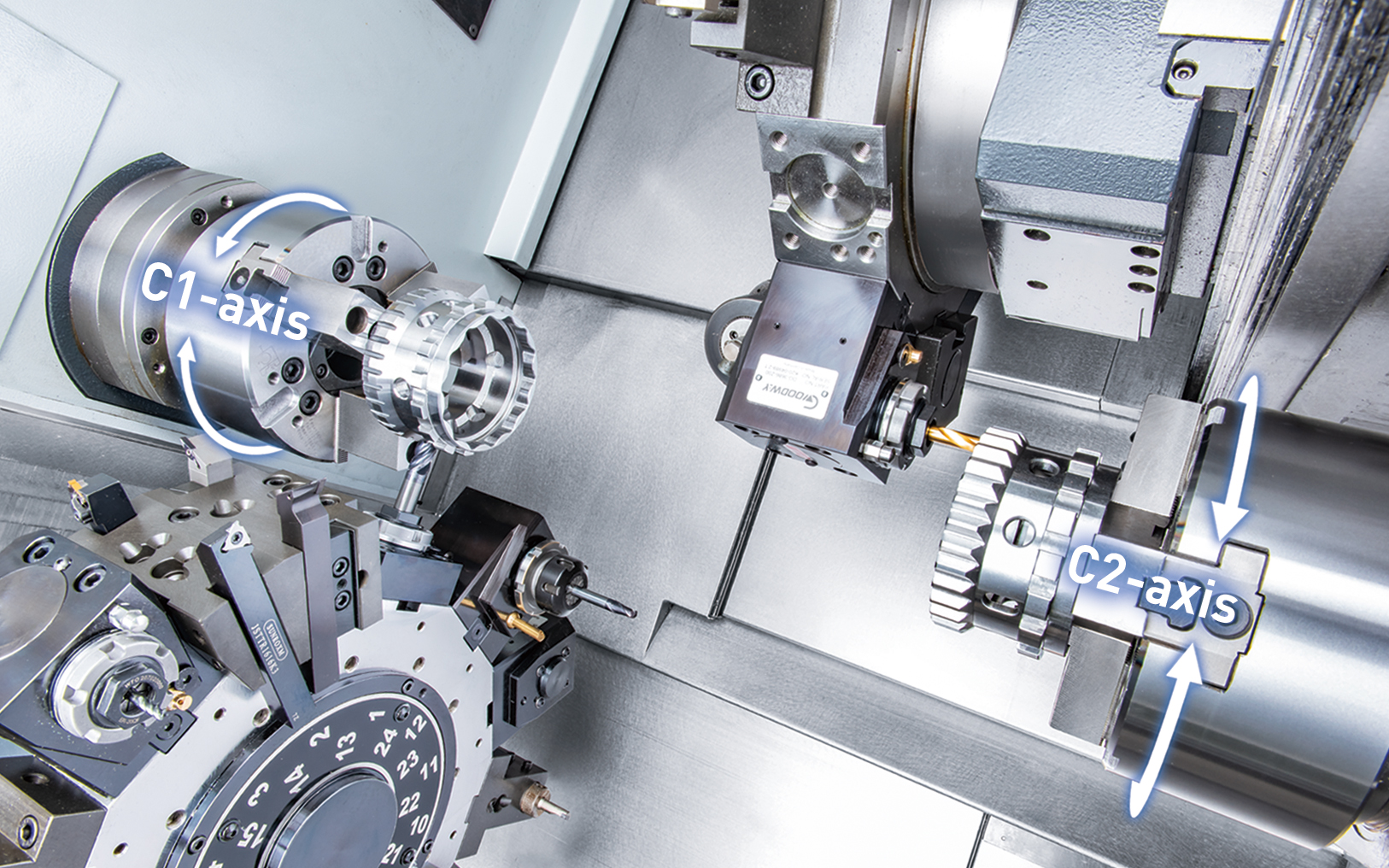

C-axis

- In our highly efficient Cs-axis design, spindle mode can be directly switched to C-axis servo mode. Fast indexing speed, along with a minimum spindle indexing angle of 0.001°, facilitates optimal performance.

- Optional C-axis function can greatly reduce the time required for twin-spindle synchronization, such as in twin spindles synchronic part catching. In average, the efficiency of C-axis synchronization is 5 times more than that of twin spindles synchronization mode.

Twin Y axes Control Function

- Y-axis control function can achieve simultaneous X, Y, Z and C axes machining, which is capable of working on Y-axis off center milling, drilling and tapping while improving the machining accuracy for multiple parts processing, such as high precision grooving and X-axis off center drilling.

- The upper and lower turrets that are equipped with Y-axis control not only allow the GTZ-1500 series to mill extremely complex parts, but also make the process arrangement more flexible than the conventional Y axes models, thereby achieving higher processing efficiency.

| Max. Y1-axis travel ( Upper turret ) | Max. Y2-axis travel ( Lower turret ) |

|---|---|

| ±42 mm | ±33 mm |