GTW-1500

With the latest technology and high quality components of the industry, GOODWAY GTW series multi-axis turning centers combined with multi-axis, high efficiency and high performance especially developed for medical & automobile industry. It can easily complete the complex front and rear side machining of work-piece with high efficiency and high precision machining performance. It's perfectly once again annotating a new standard of multi-axis turning center.

- Twin spindles, upper turret, lower gang type tooling design, twin Y-axis control as standard features.

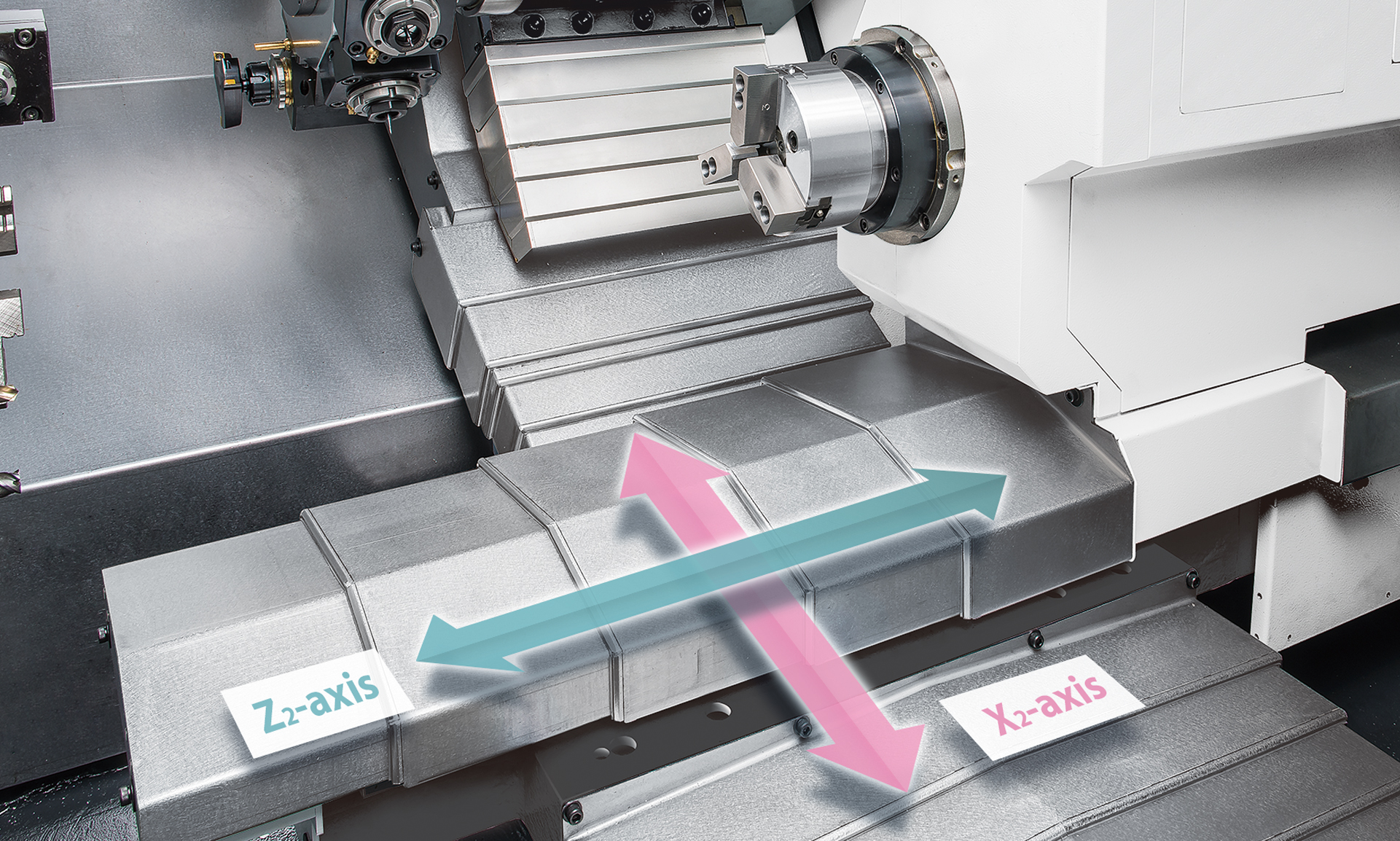

- Innovative X2-axis control significantly enhances machining flexibility.

- A single machine integrates the machining capabilities of both turret type and SWISS type turning centers.

- The low-center-of-gravity Meehanite cast-iron base provides an exceptionally stable foundation for the main spindle, sub-spindle, and turret.

- X1 / X2 / Y1 / Z1 axes feature high-precision, low-wear linear guideway design.

- Y2 / Z2 axes adopt a high-rigidity box way design, ensuring excellent heavy-duty cutting performance during rear-side machining.

- Both main and sub spindles feature a built-in motor design with forced external cooling circulation to suppress thermal displacement, ensuring exceptional machining accuracy.

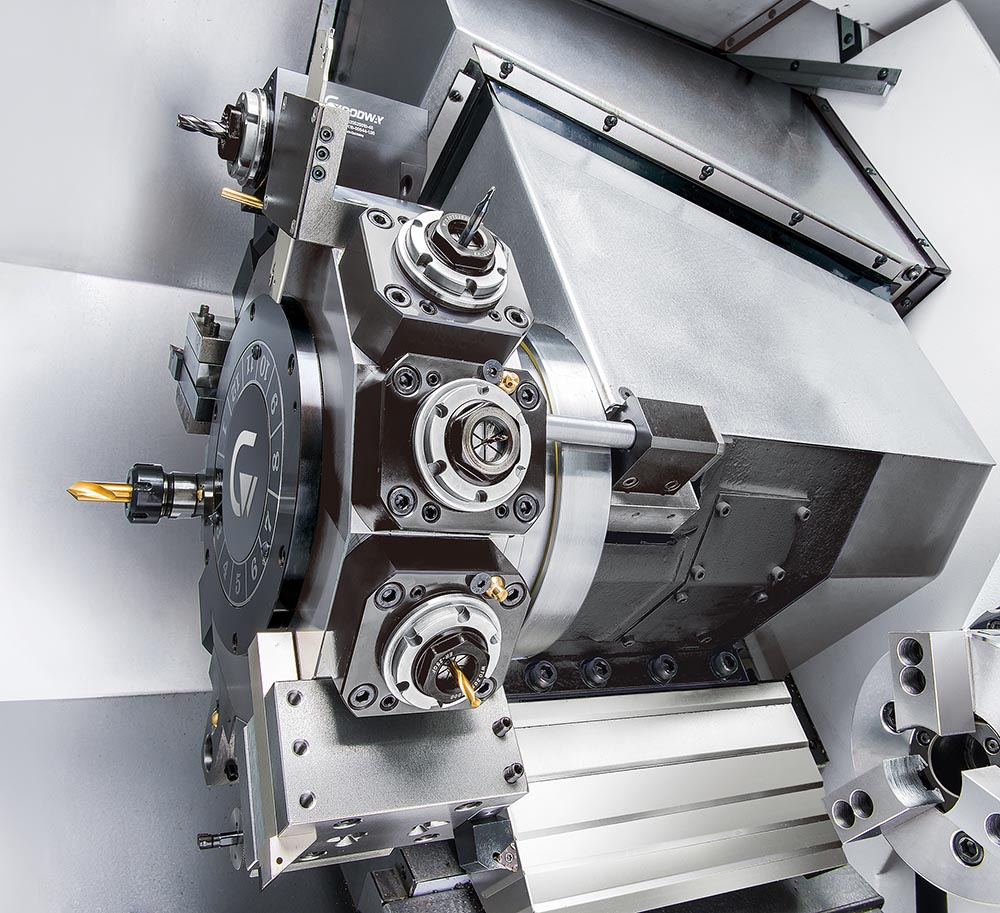

- The 12-station live tooling turret accommodates 12 live tools, with a maximum tool speed of 4,000 rpm.

- Standard Y-axis control provides machining capability for complex-shaped workpieces, with Y1-axis travel range of ±35 mm.

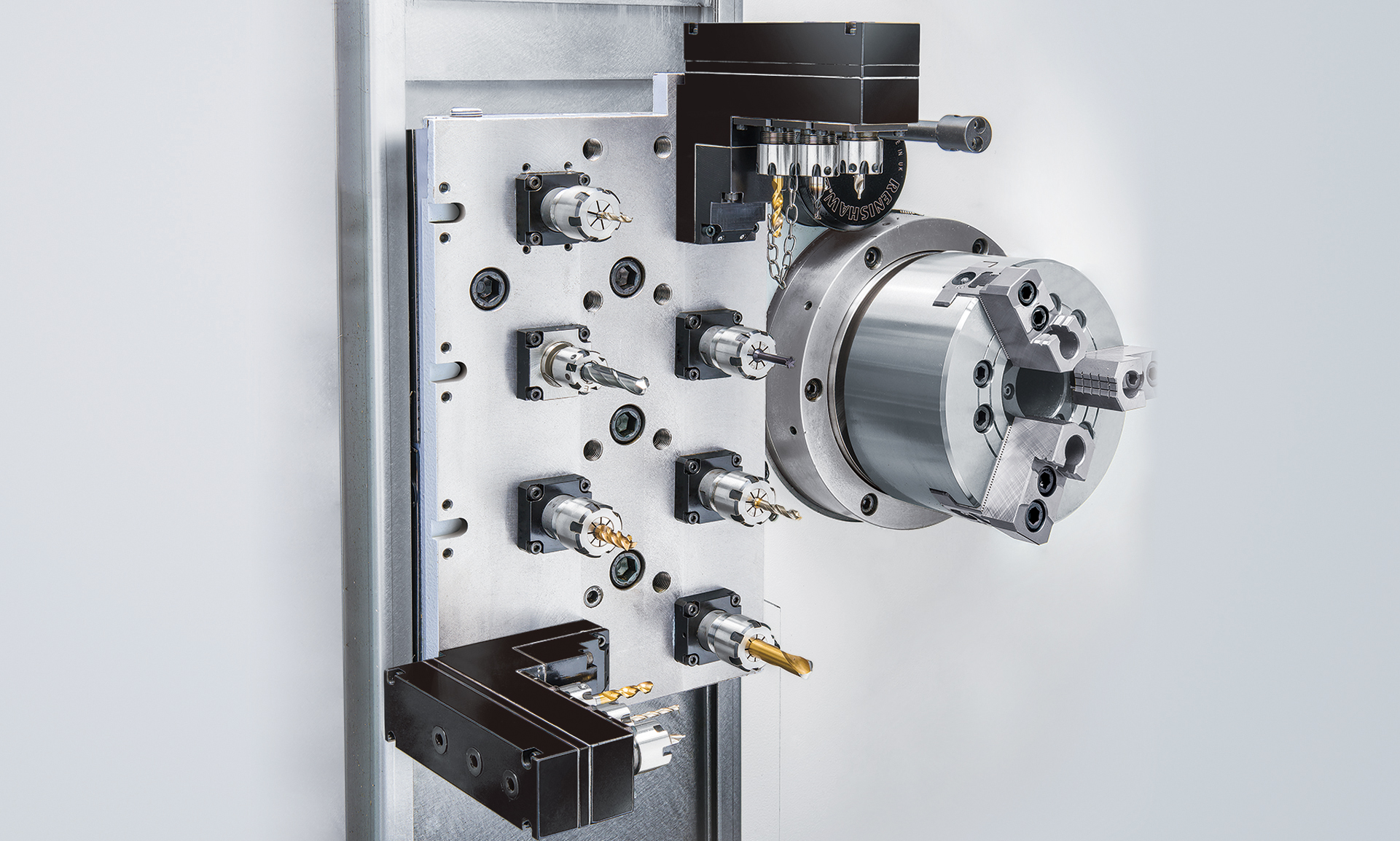

- The 8-station gang type tooling system design enables faster tool changes and more efficient rear-side machining.

- The Y2-axis travel range of 250 mm provides enhanced machining flexibility for this series.

Features

High Rigidity Structure

Powerful Cutting Capability

Machining Capability for Complex-shaped Workpieces

High-efficiency Rear-side Machining Capability

Model Variations

Y

- Live tooling turret

- Gang type tooling system

- C-axis

- Y-axis

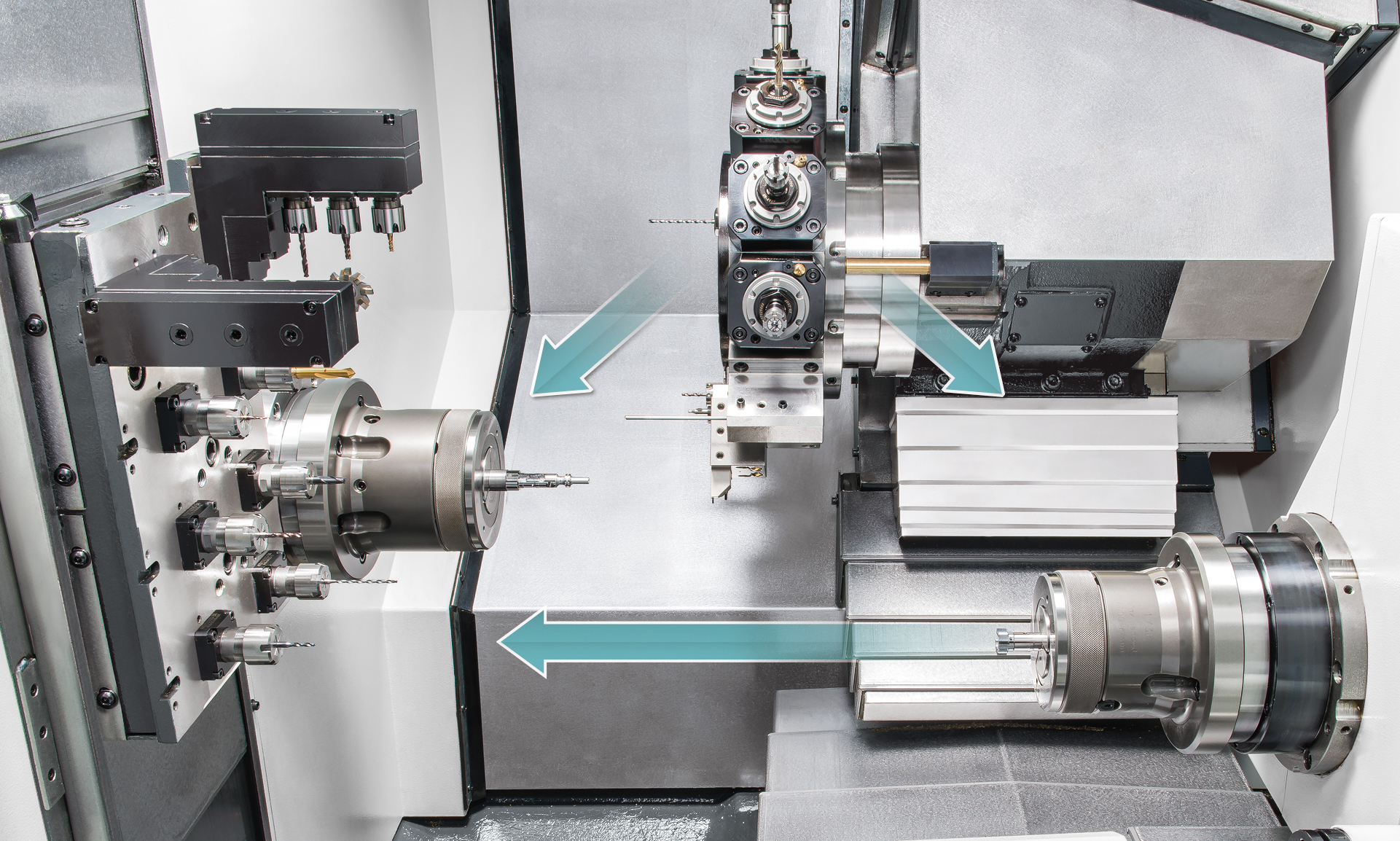

Flexible machining mode

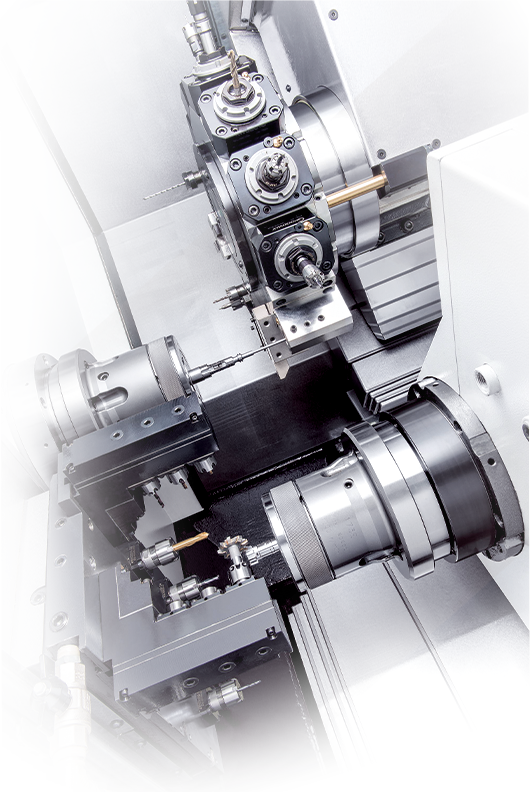

The Z1-axis features a high-rigidity 30° slant bed design

X2 & Z2 axes of the sub-spindle

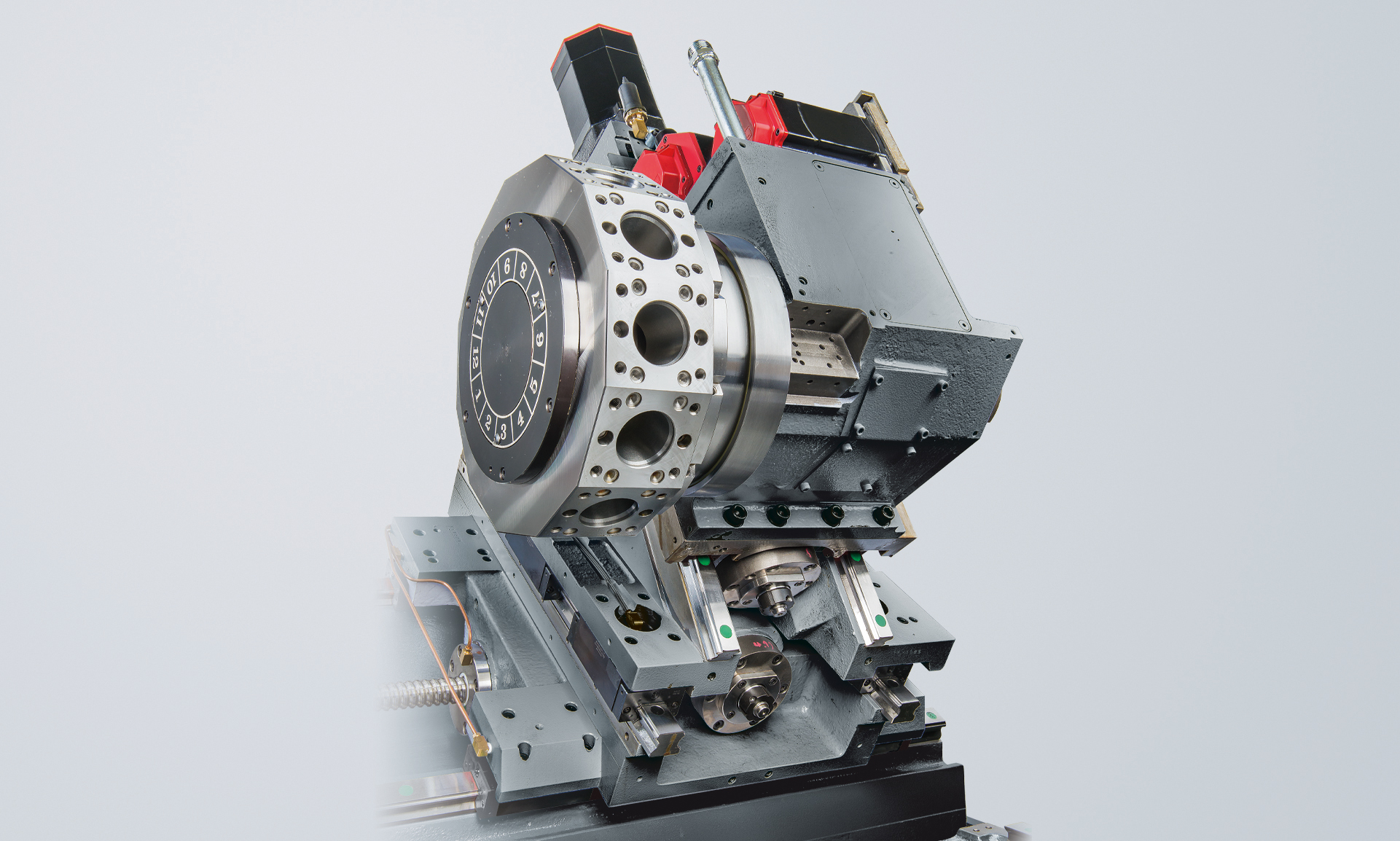

Rear gang type tooling system

Live Tooling Turret

- Heavy load servo indexing turret features the latest turret technology, achieving 0.2 second indexing for adjacent stations and 0.5 second for stations at the opposite end of the disk.

- The live tooling turret accommodates 12 live tools, and only the tool at the working position rotates. This design improves energy efficiency and reduces wear.

Y1-axis Control Function

- Y1-axis travel : 70 mm = ± 35 mm, Y1-axis and X1-axis direction included angle 30°, the gravity of turret is always located on the range of the saddle to ensure the rigidity of full travel.

Y2-axis & Gang Type Tooling System

- The gang-type tool post supports 8 live tools, driven by an AC servo motor. The high-torque output delivers ample power, enabling even the most demanding machining tasks with ease.

- The Y2-axis offers 250 mm of travel and a rapid feed rate of 24 m/min, enabling fast tool changes and precise contour milling capability.