GTS

Compact machine dimensions, exceptional cutting performance, and comprehensive automation

capabilities.

Refined through years of user feedback, the GTS series delivers unmatched performance and

reliability.

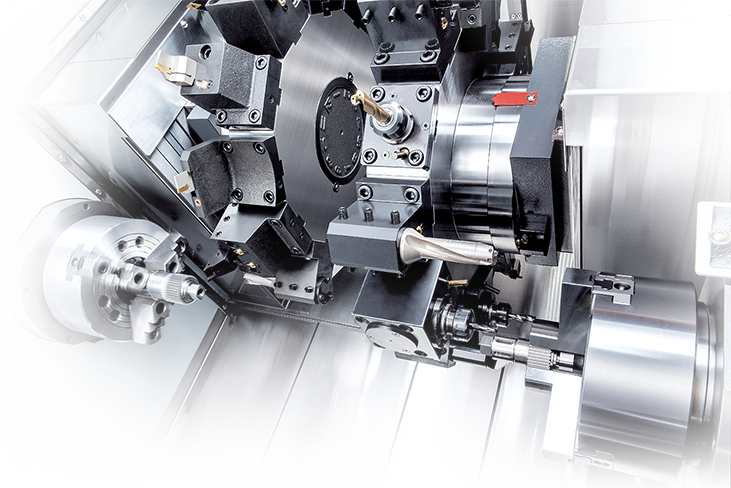

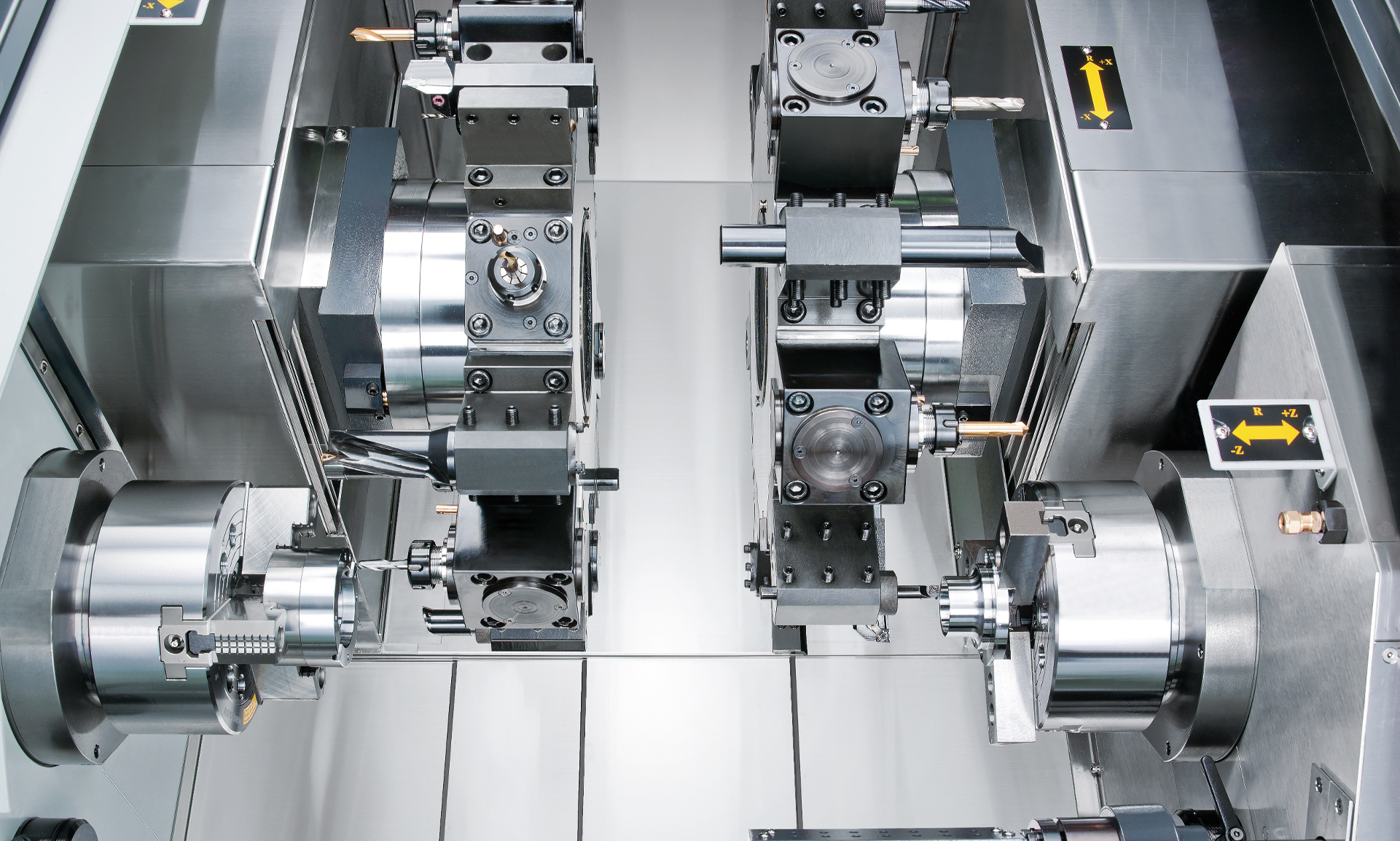

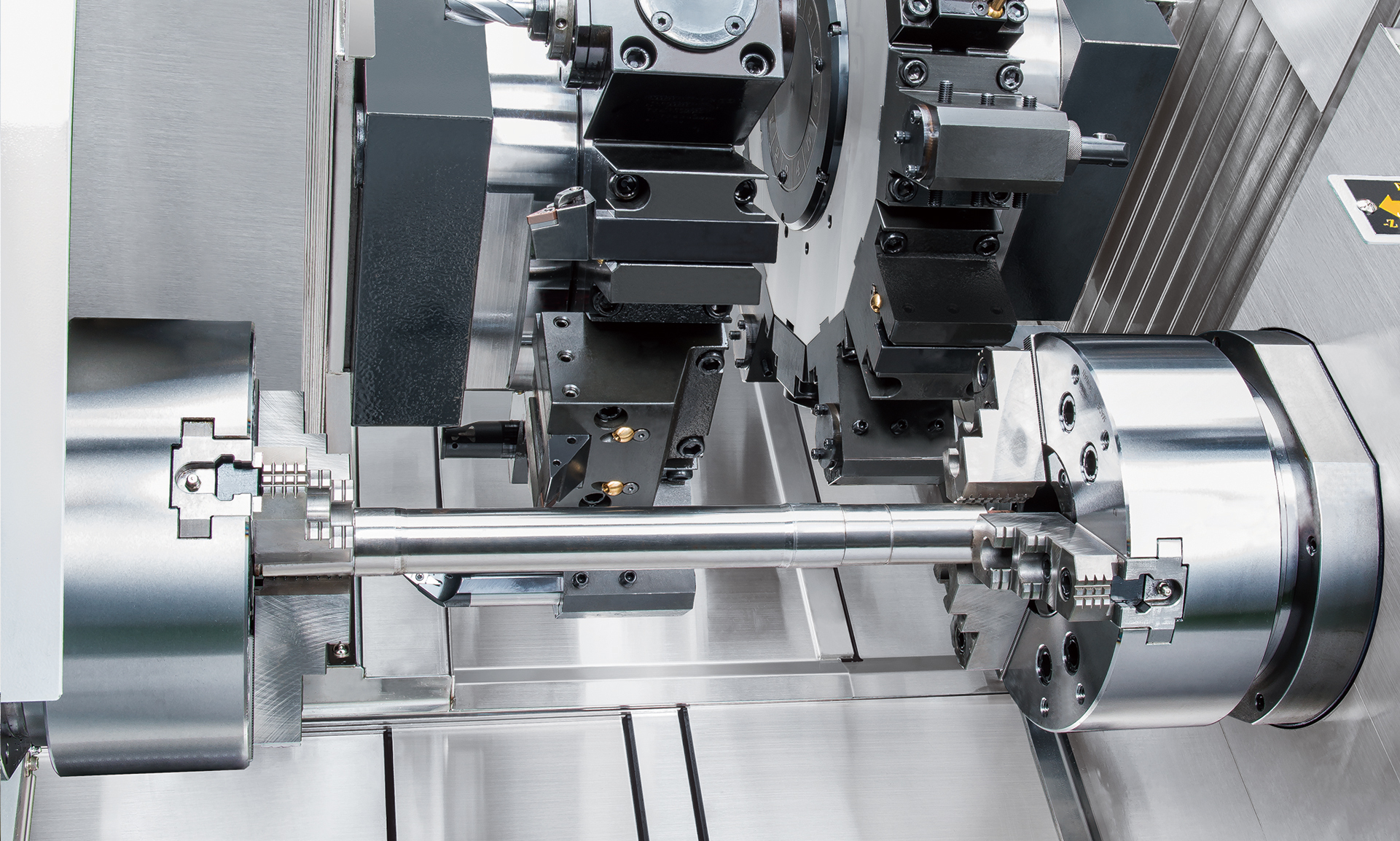

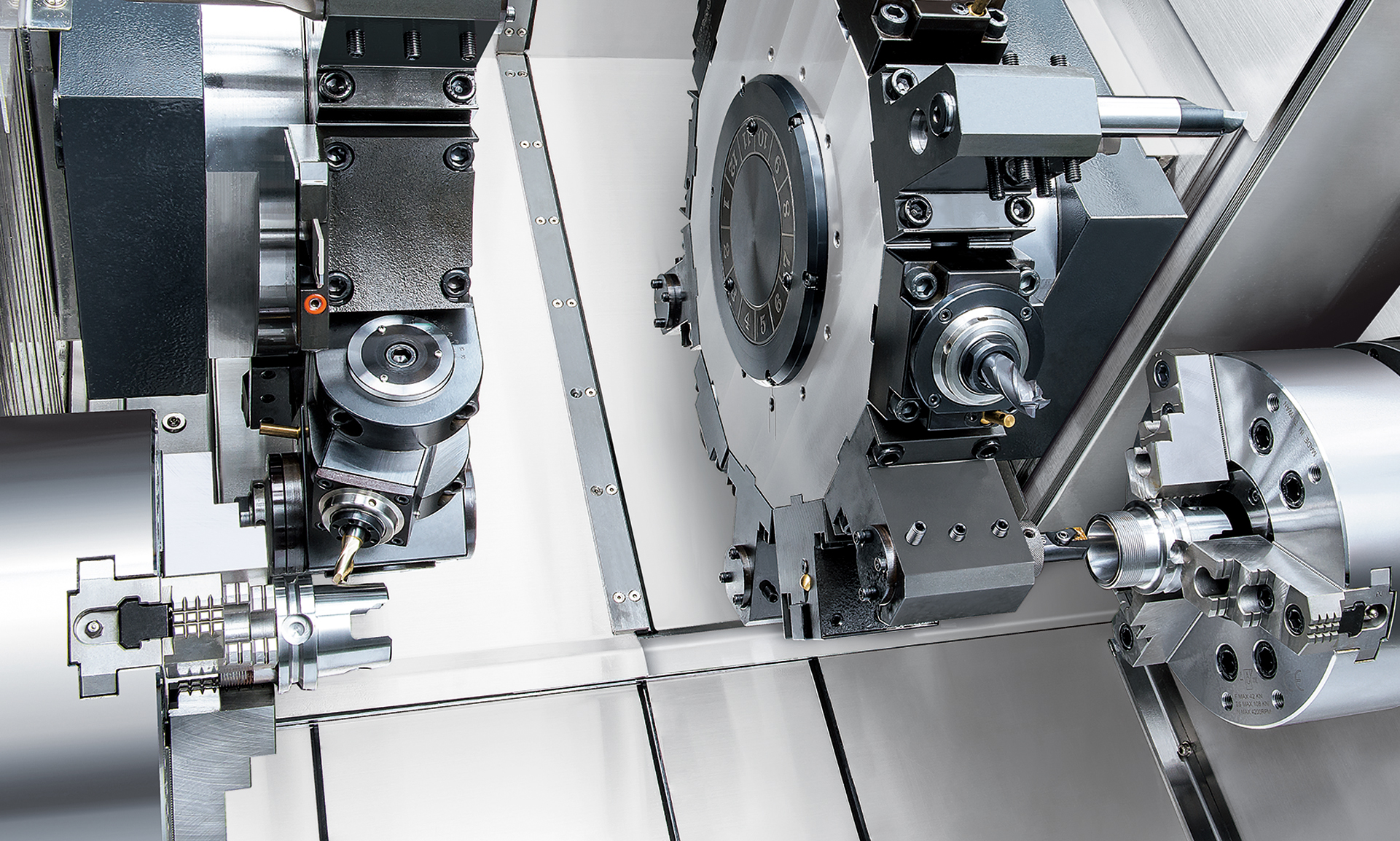

- The opposed twin spindles and twin turrets design allows for optional Y-axis control functionality on both turrets.

- Reliable performance and quality, selected by leading European automotive parts manufacturers for their equipment.

- Super rigidity one-piece 45° slant bed structure.

- The GTS-150 series X/Z axes feature a high-precision, low-wear linear guide rail design.

- The GTS-200 series features a high-rigidity box-way design.

- The 12-station servo turret enables rapid tool changes and delivers outstanding cutting rigidity for high-performance cutting.

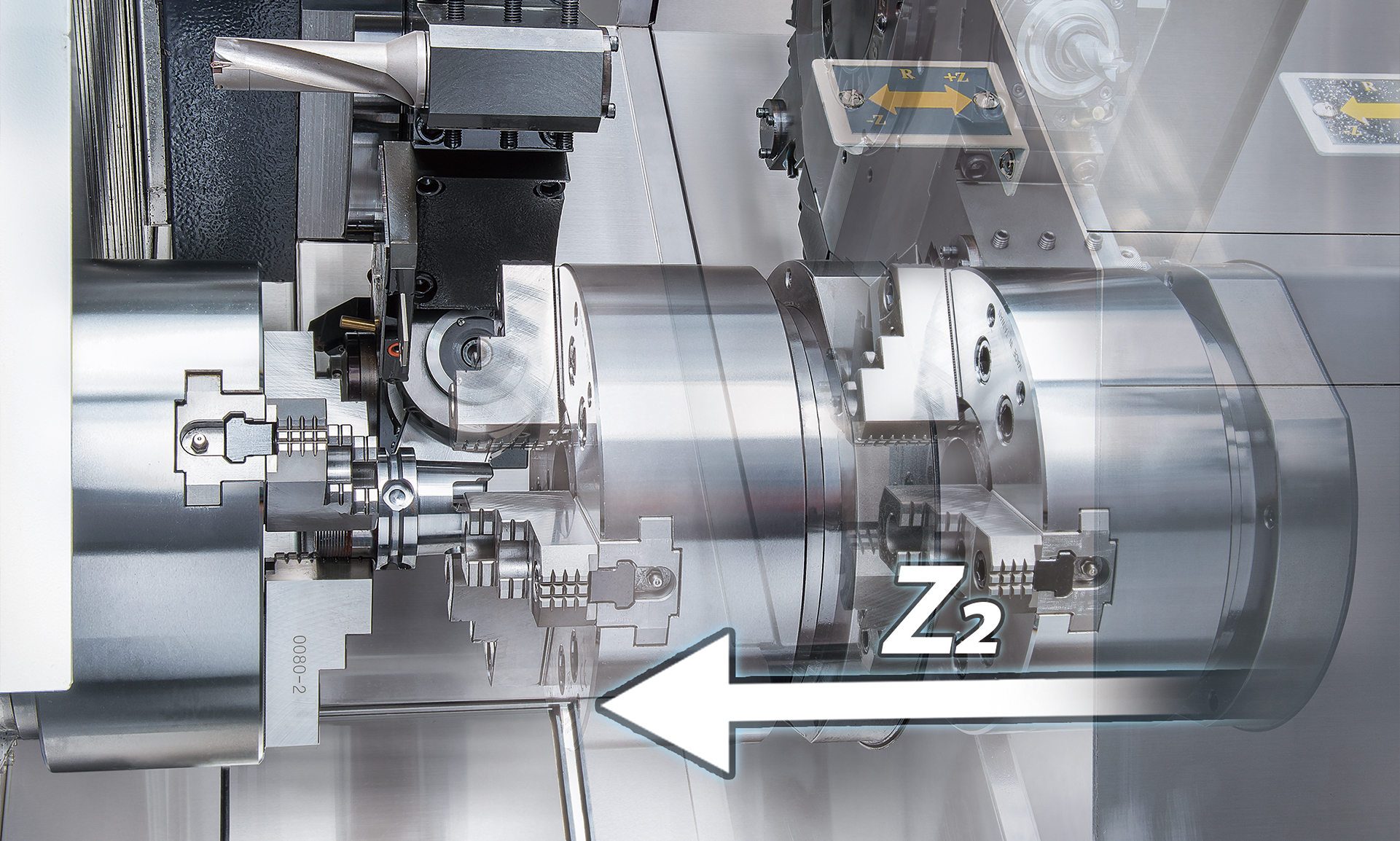

- Both the spindle 1 & 2 are designed with the same specifications, allowing for front and rear machining of workpieces to be completed directly on a single GTS series.

- The spindle offers three specifications for bar capacity, paired with different speed options, with a maximum spindle speed of up to 6,000 rpm ( Ø42 mm ).

- Optional 12-station live tooling turret is available, with a maximum live tooling speed of up to 4,000 rpm.

- Optional twin Y axes control function is available, with a travel range of ±30 mm (GTS-150) / ±60 mm (GTS-200).

Features

High Rigidity Structure

Tooling System

Powerful Cutting Capability

Integrated Machining Functions

Model Variations

X

- Turret

- Turret

- Live tooling turret

- Live tooling turret

- Y-axis

- Y-axis

MX

- Turret

- Turret

- Live tooling turret

- Live tooling turret

- Y-axis

- Y-axis

MMX

- Turret

- Turret

- Live tooling turret

- Live tooling turret

- Y-axis

- Y-axis

XY

- Turret

- Turret

- Live tooling turret

- Live tooling turret

- Y-axis

- Y-axis

Twin spindles, twin turrets

Spindle 2 catches parts automatically

Twin spindles simultaneous cutting

Front / rear side synchronous cutting

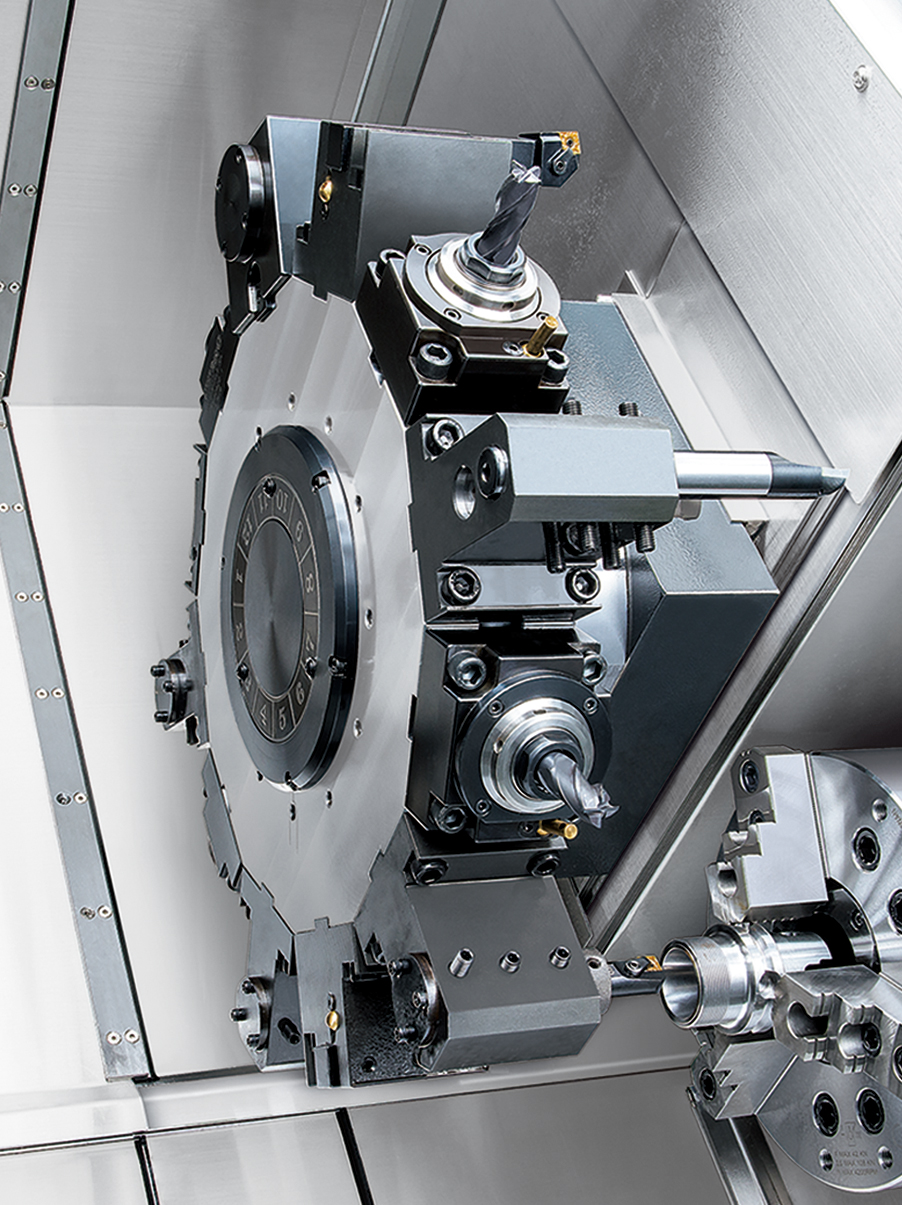

Live tooling turret

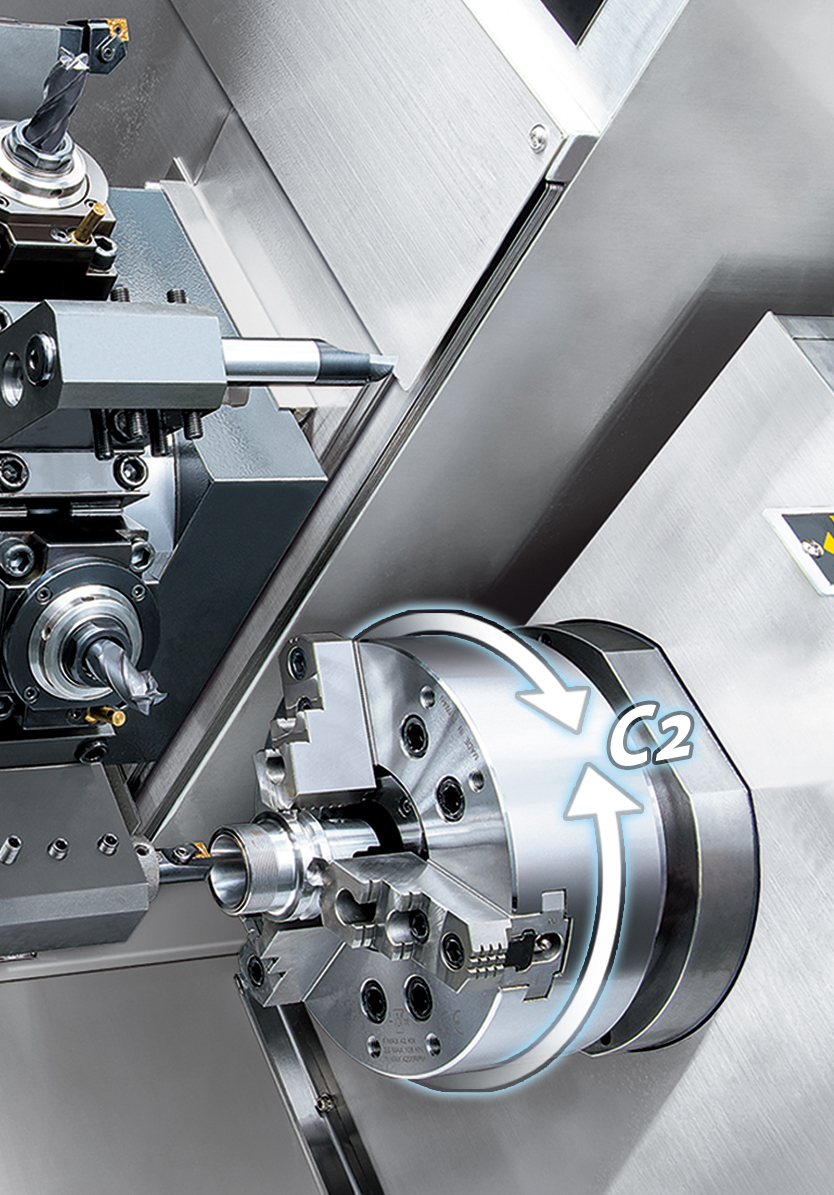

C-axis

Live Tooling Turret

- Live tooling turret is driven by a servo motor and uses a high-precision curvic coupling for accurate turret indexing, ensuring fast tool changes and excellent rigidity.

| Turret type | T12 | T6 |

|---|---|---|

| Stations | 12 | |

| Live tooling stations | 12 | 6 |

| Tool drive | Rotate in working position only | Rotate at the same time |

C-axis

- The C-axis features an ultra-high rigidity Cf-axis combined with a disc brake system, driven by a high-torque FANUC servo motor with 240 Nm (cont.) output. It ensures excellent surface machining accuracy and maintains dynamic precision within ±0.02°, even under heavy cutting conditions.

| Models | C-axis Torque Output |

|---|---|

| GTS-150 | 120 Nm |

| GTS-200 / 260 | 240 Nm |

Twin Y axes Control Function

- Optional Y-axis function can achieve X, Y, Z and C axes simultaneously machining, which allows the series can work on Y-axis off center milling, drilling and tapping as well as improving the machining accuracy from a regular 3 axes simultaneously machining processes under certain condition.

| Models | Max. Y-axis travel |

|---|---|

| GTS-150 | 60 ( ±30 ) mm |

| GTS-200 | 120 ( ±60 ) mm |

| GTS-260 | 120 ( ±60 ) mm |