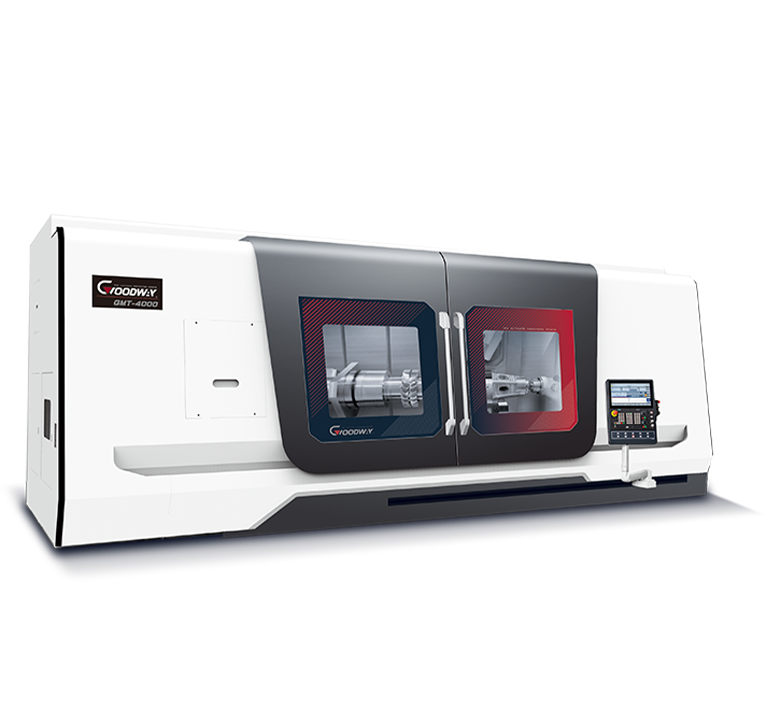

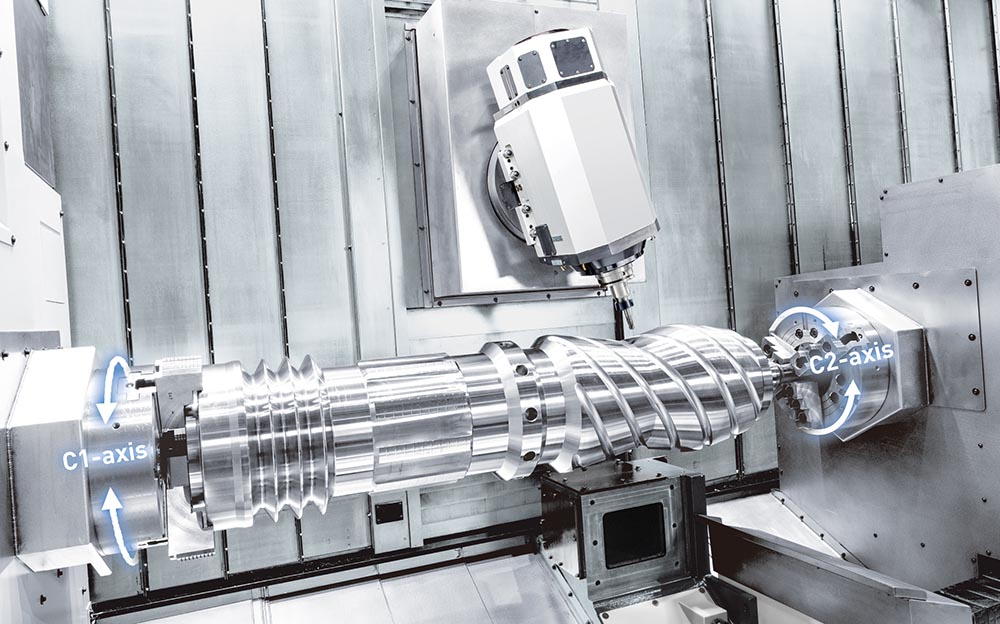

GMT-4000

To have a differentiated competitive edge and maximizing the reduction of labor costs in the rapidly changing market will be crucial elements for gaining profits. Undoubtedly the GOODWAY GMT-4000 series is the best choice to correspondence this challenge.

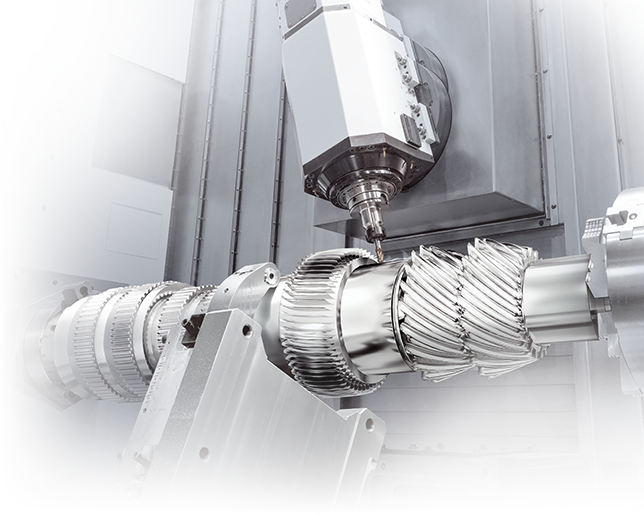

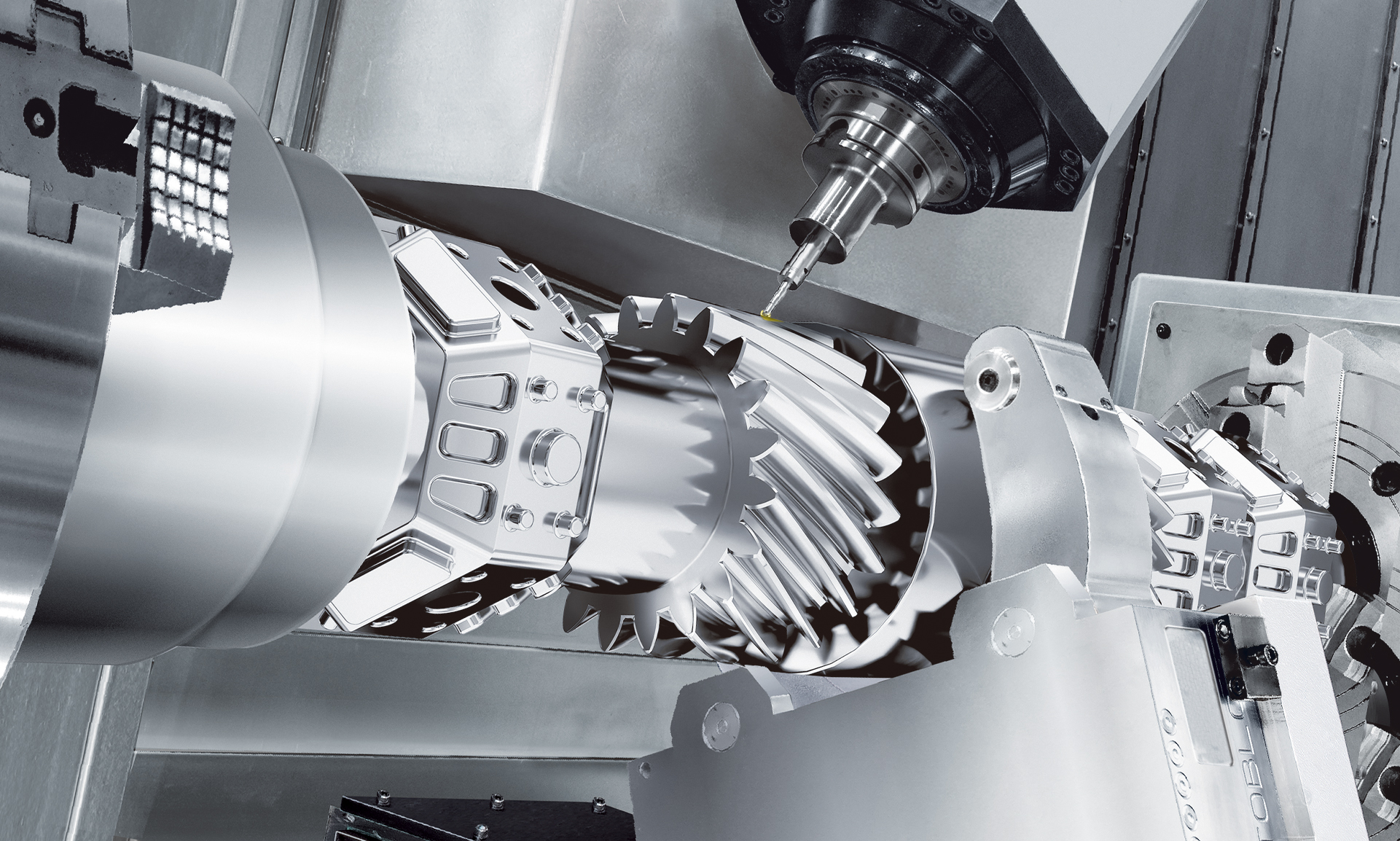

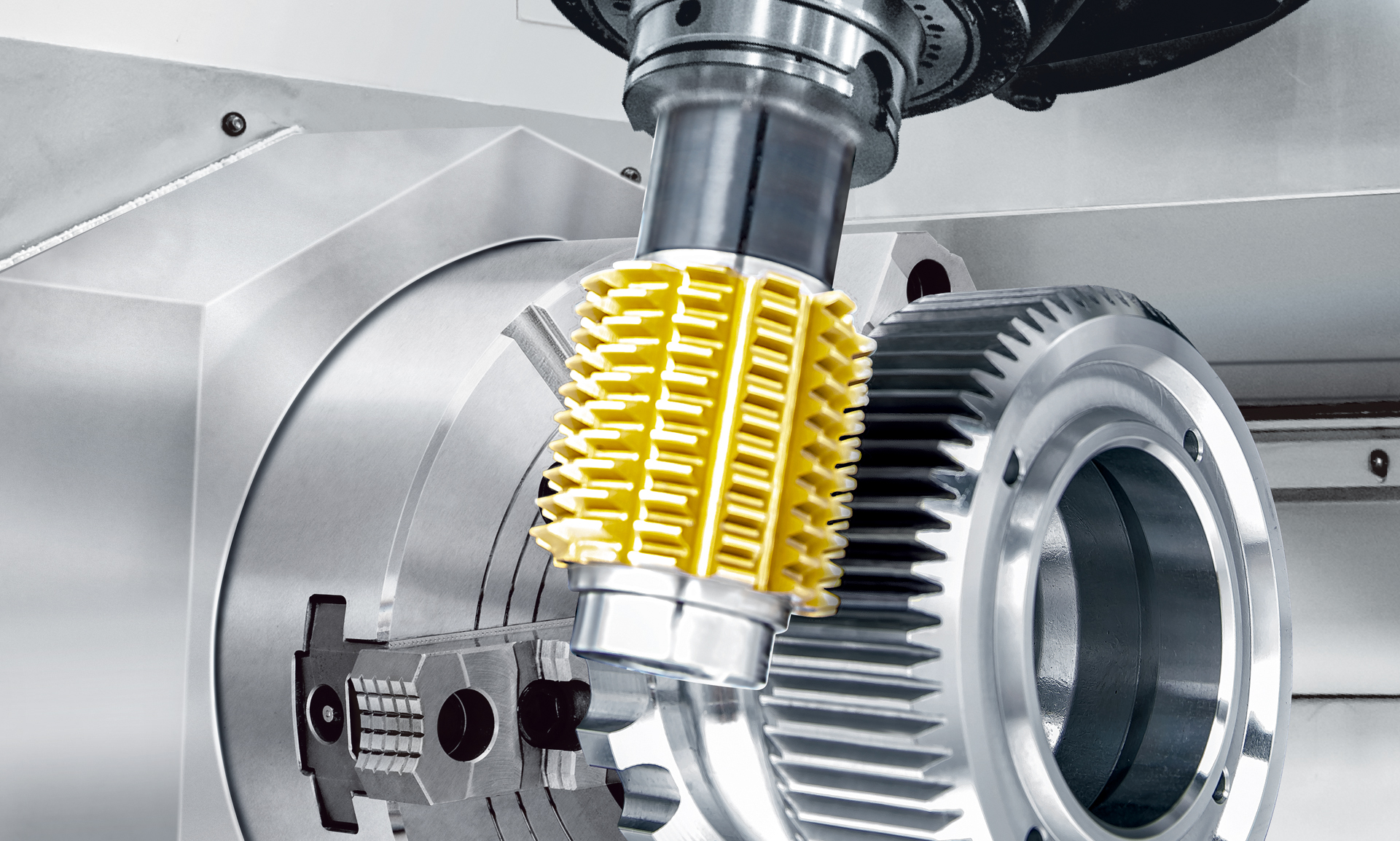

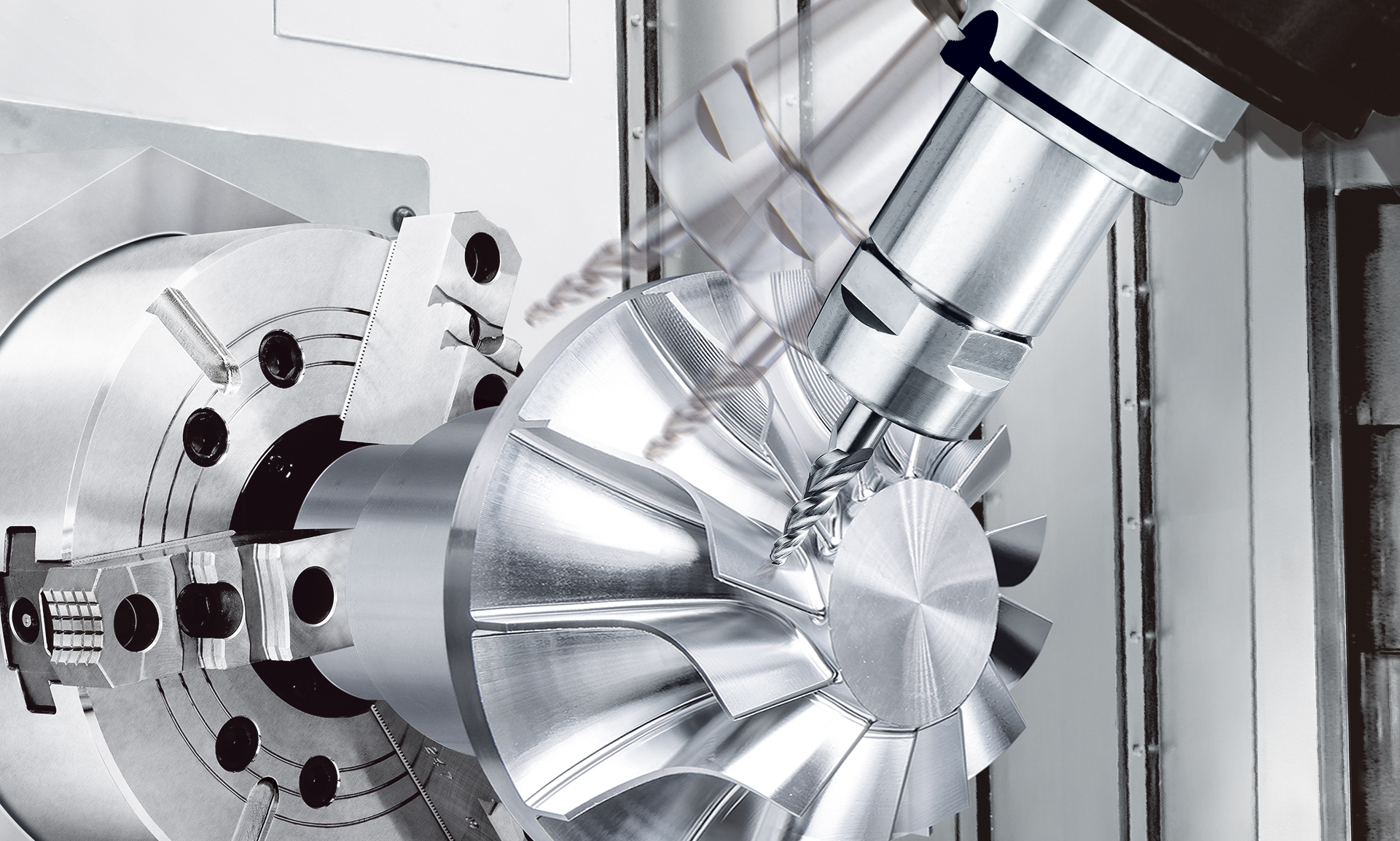

This series features 8 axes control and the ability for interpolation of B、C、X、Y、Z axes. It can achieve the comprehensive process such as turning, milling, drilling, gear hobbing and power skiving and auto workpiece measuring by single machine, as well as handle the complex geometric contour machining with high accuracy. One GMT-4000 series machine can replace most equipment in production lines and bring you an unprecedented machining experience.

- 8 axes control with simultaneous 5 axes milling capability, an all-purpose, versatile model.

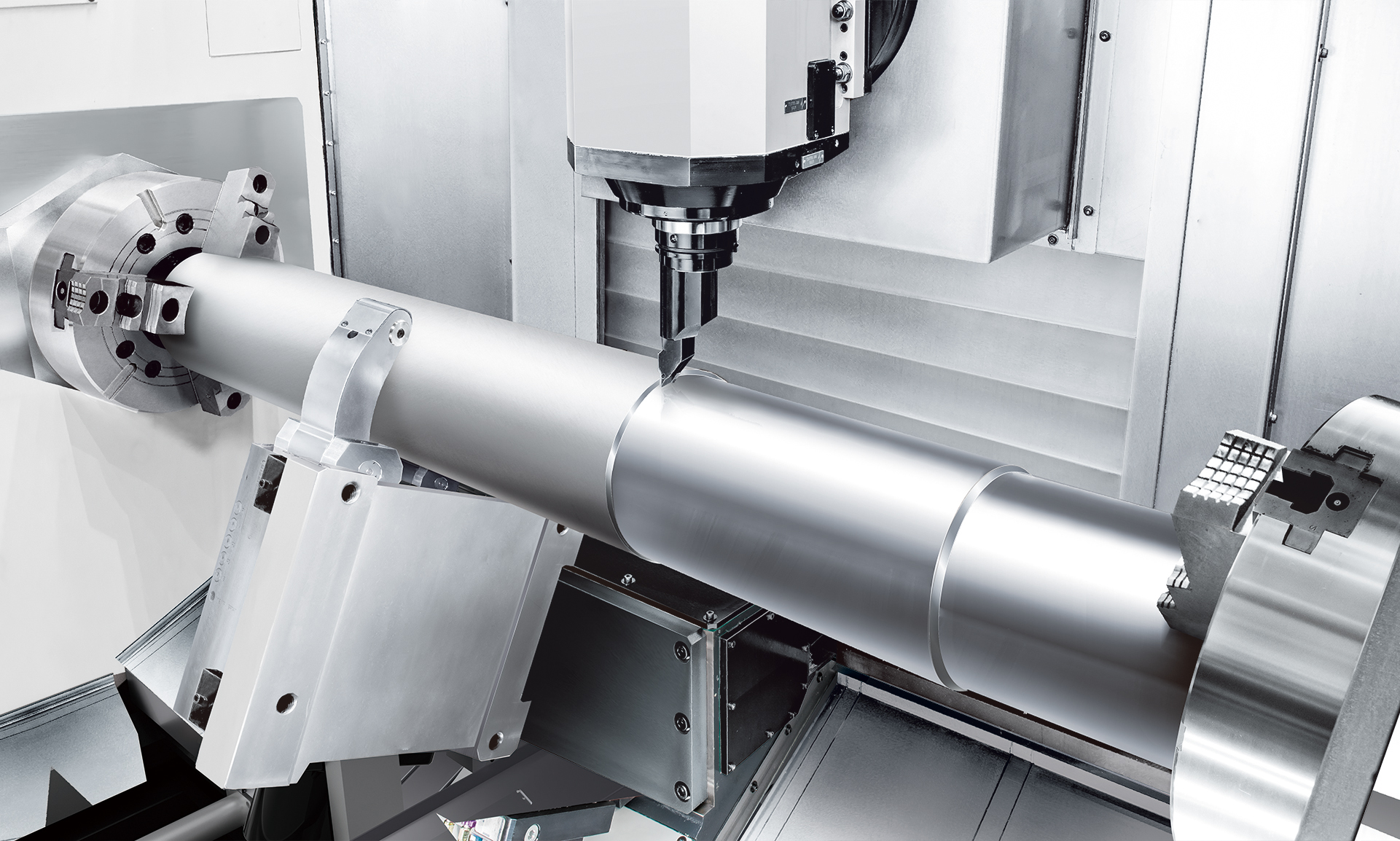

- Extra-large machining capacity with a maximum turning diameter / length: Ø820 / 3,055 mm

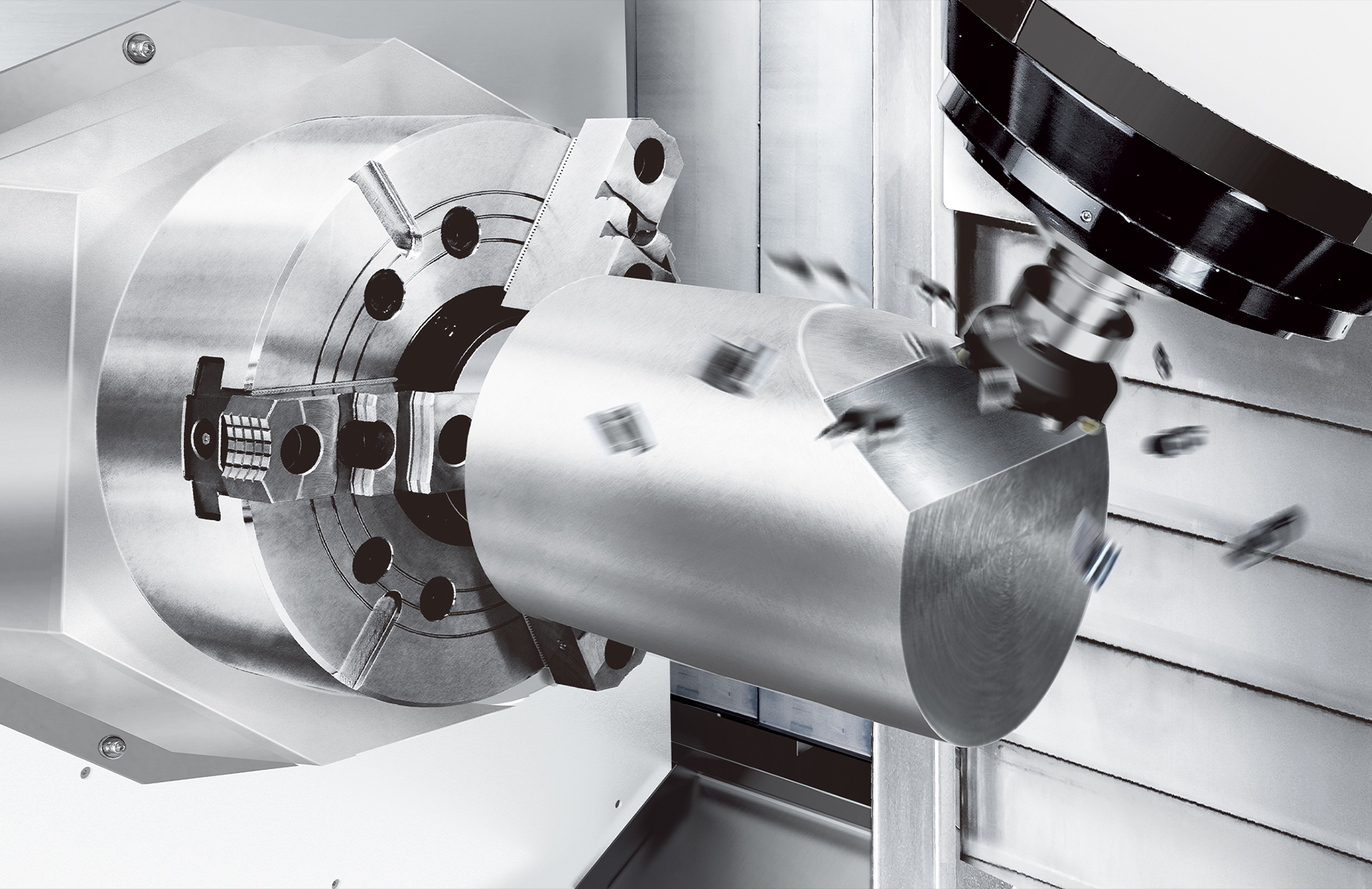

- 34 kW built-in spindle design provides 188 Nm of continuous torque output at low-speed ranges.

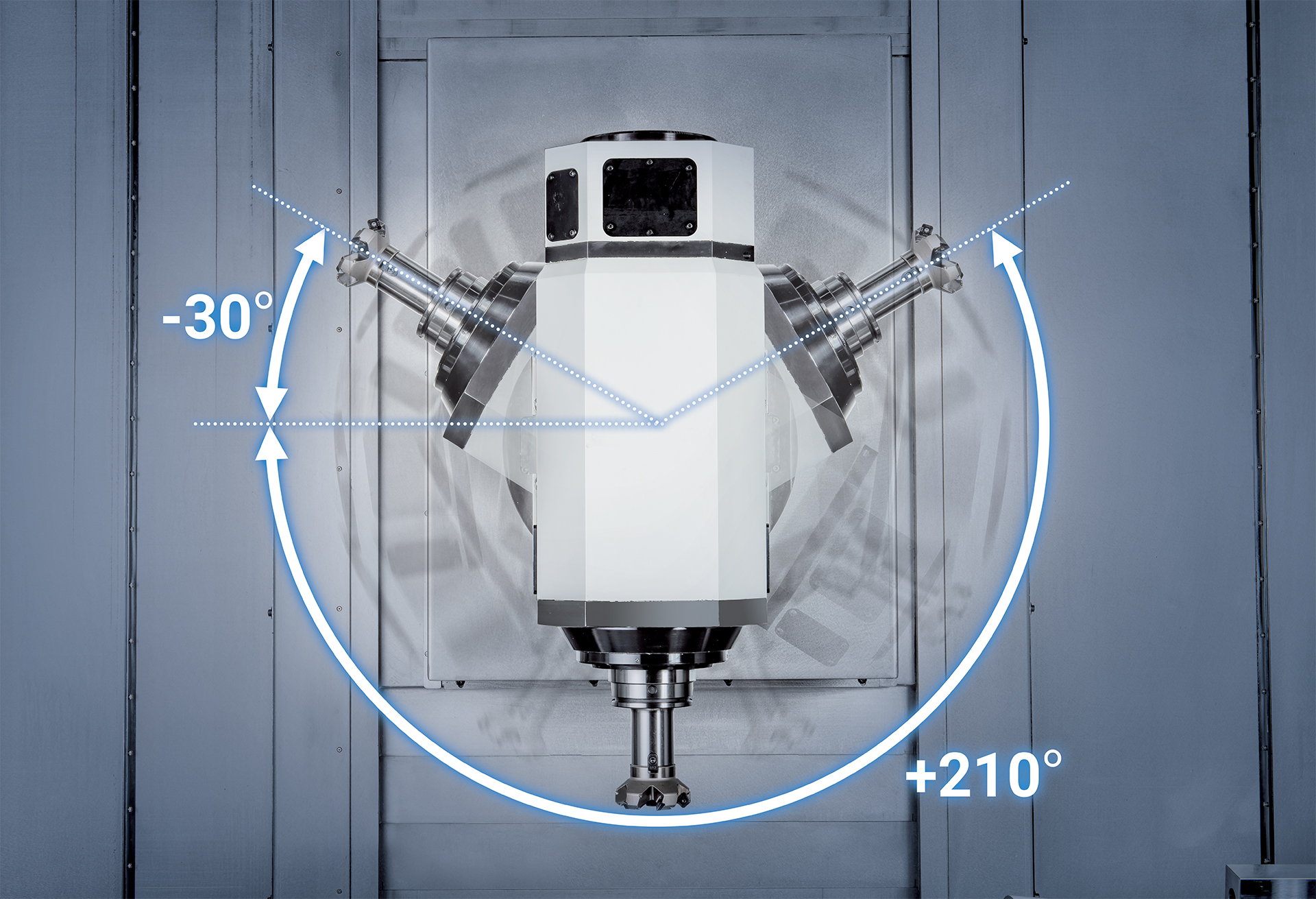

- The B-axis is equipped with a 0.001° high-resolution angle encoder as standard, with a travel range of 240°.

- The Y-axis offers a maximum travel distance of ±250 mm from the spindle center, providing greater machining flexibility.

- 40T chain-type tool magazine with a arm type ATC system, supporting tool size up to Ø260 mm (adj. pocket empty) x 500 mm.—delivering maximum flexibility for a wide range of machining needs.

- 80T / 120T tool magazine is also available as an option.

- The spindle gearbox is driven by a 32 kW (60%) built-in motor, capable of delivering an impressive 3,345 Nm of torque output at low-speed ranges.

- Optional automatic centering steady rest provides stable support for the workpiece. It is driven by a servo motor and can be moved to the desired position through NC programming.

- Both the spindle and tool spindle are equipped with a cooling oil circulates design, effectively suppressing thermal displacement to ensure ultimate machining accuracy.

- Optional thermal compensation system.

Features

Tool Spindle Equipped with B-axis

High-reliability ATC System

Powerful Cutting Capability

Precision Enhancements

Model Variations

- Spindle 2

spindle

Milling Spindle

- The built-in motor design can reduce the rotation vibration of the spindle, extend the life of the spindle, and ensure processing accuracy under long-term operation.

- Maximum spindle speed up to 10,000 rpm and providing a maximum torque of 188 Nm ( cont. ) at 1,725 rpm to meet various working conditions.

B-axis

- The milling spindle comes with many features such as high speed, high precision, low interference, etc.; it can continuously index every 0.001° within the 240° B-axis travel range. Not only to perform heavy cutting on fixed angle, but also perform 5 axes simultaneous motion contour milling, with extremely flexible processing capabilities.

- B-axis can equip with either DD ( Direct Drive ) motor with zero backlash, high-dynamic performance, or a super rigidity roller cam drive mechanism, depending on actual requirement to meet various machining characteristics.

C-axis

- Designed with a high-resolution servo motor combined with a disc brake system ( Cf axis ), the torque output can reach 2,100 Nm ( cont. ), the rigidity is much better than that of similar models, and it can maintain ultra-high dynamic accuracy even under heavy cutting.

- The brake system adopts the design of all-axial hydraulic brake and disc brake disc, which has the characteristics of high rigidity, heavy cutting resistance, and extremely high resistance to vulcanization.

ATC System

- The chain type magazine is combined with the design of the arm type ATC system, which has ample tool capacity, fast and reliable tool change, can significantly save non-cutting time, and can meet the processing needs of complex workpieces.

- Standard 40T ATC magazine. ( 80T or 120T magazines are optional ) .

Back Processing Capacity

- The spindle 2 adopts the same specification design as the spindle 1, which can provide the same powerful cutting ability on the front and back of the workpiece.

- The spindle 2 can also use the C-axis function with the same specifications as the spindle 1, and the minimum positioning index can reach 0.001°