GMT-2000

Looking for advanced processing equipment, with both high productivity and processing capacity for complex workpieces, as well as excellent cost performance. The seemingly impossible task will be fully achieved by GOODWAY GMT-2000 series.

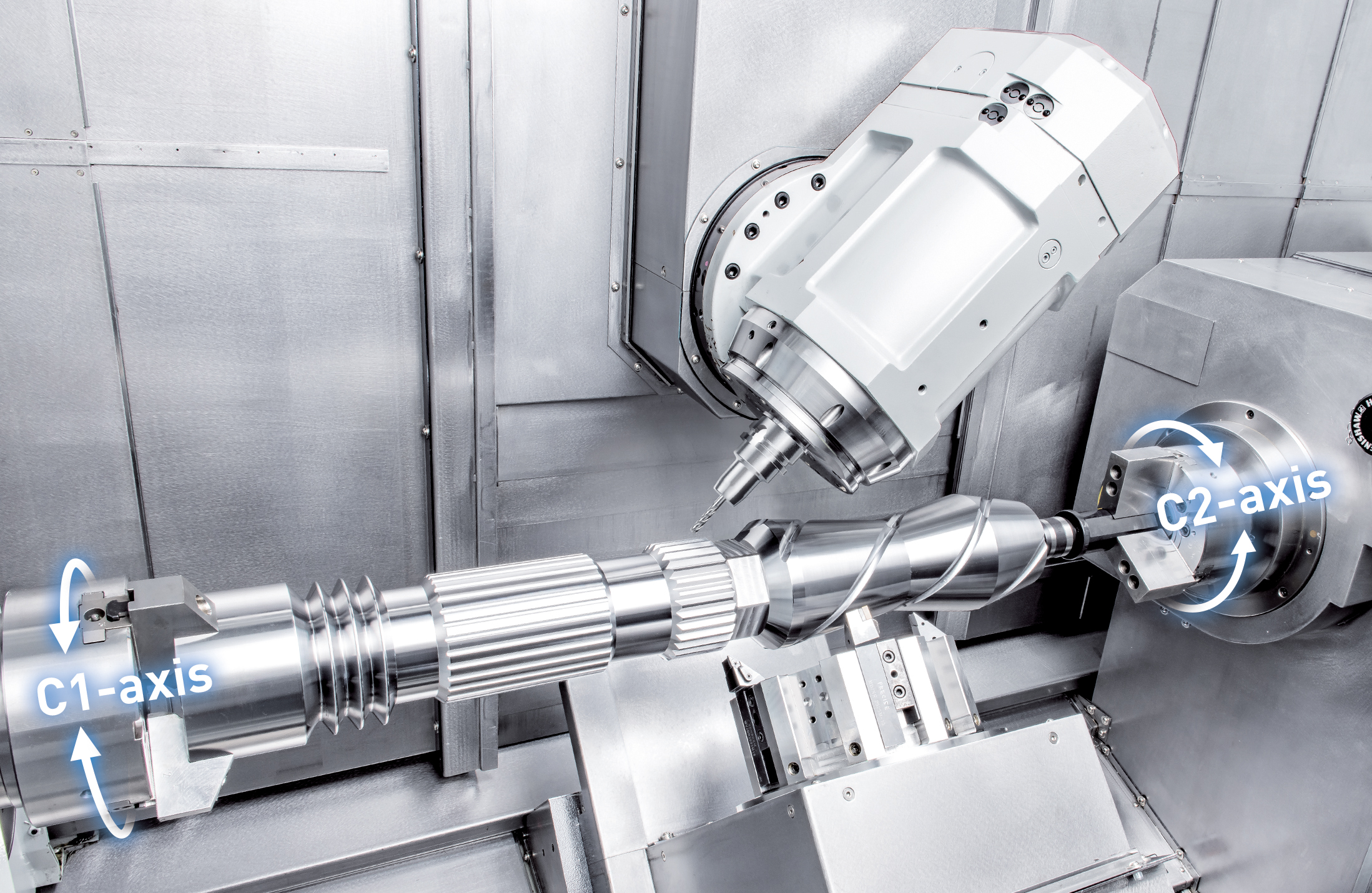

The GMT-2000 series integrates the functional characteristics of turning centers and machining centers into one. It has the highest 9 axes control and 5 axes simultaneous machining capabilities. It can not only efficiently complete various complex shapes of workpieces, but also easily overcome the need for heavy cutting. This is a versatile model that can be used in all industries.

In addition, the optional G.LINC smart operating system and various automation system can further improve production efficiency, reduce manufacturing costs, and fully meet all your processing needs today and tomorrow.

- The ultimate all-in-one machine with 9 axes control and 5 axes simultaneous machining.

- The configuration of the tool spindle and lower turret enables more flexible and versatile process planning.

- The 20.8 kW built-in spindle design with a maximum speed of 12,000 rpm meets a wide range of machining needs.

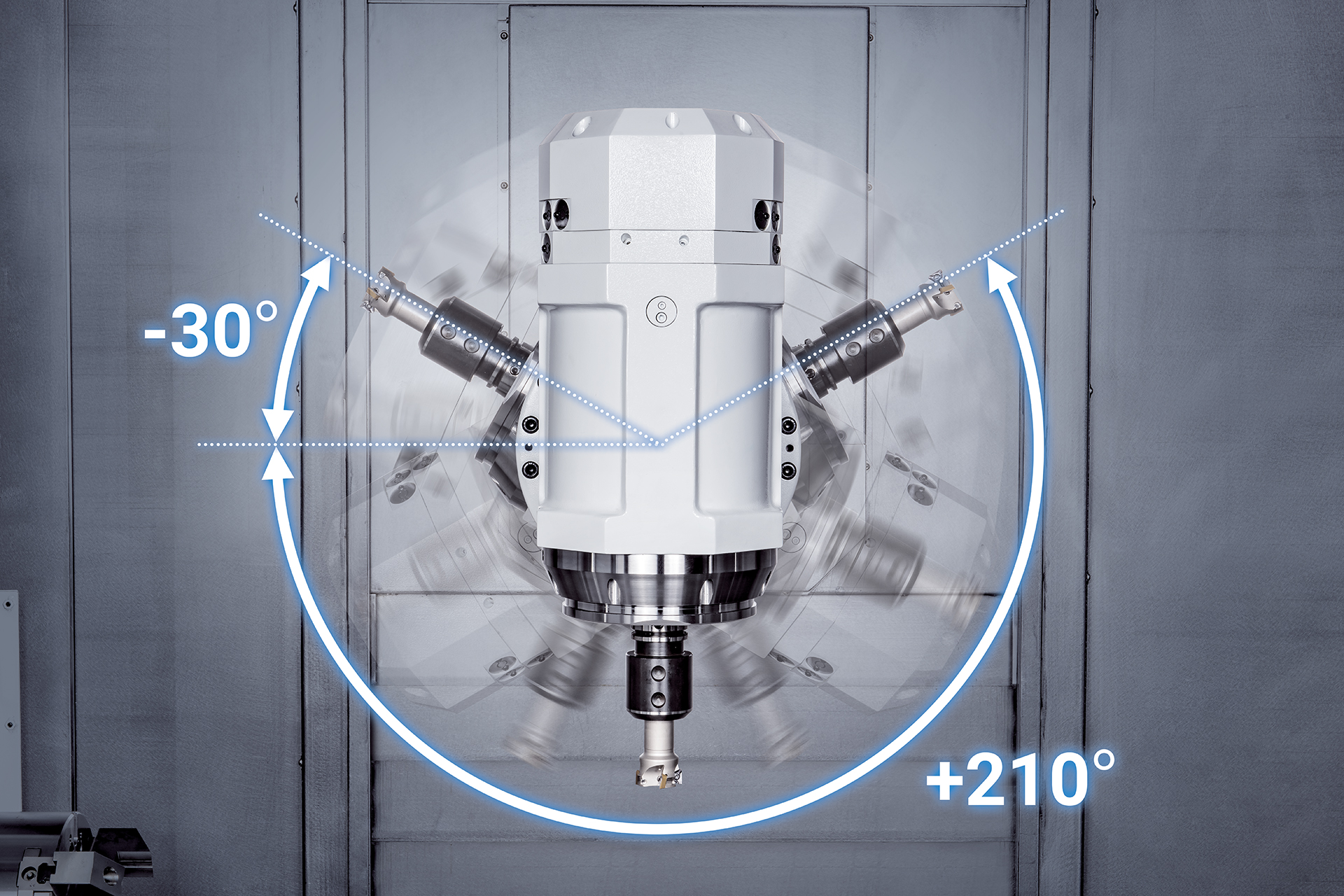

- The B-axis is equipped with a 0.001° high-resolution angle encoder as standard, with a travel range of 240°.

- The Y-axis offers a maximum travel distance of ±150 mm from the spindle center, providing greater machining flexibility.

- 40T chain-type tool magazine with a arm type ATC system, supporting tool size up to Ø130 mm (adj. pocket empty) x 450 mm.—delivering maximum flexibility for a wide range of machining needs.

- 80T / 120T tool magazine is also available as an option.

- The built-in spindle design delivers a maximum torque output of 1,450 Nm, with maximum spindle speeds corresponding to chuck sizes (12" / 10" / 8") at (3,200 / 3,800 / 4,500 rpm) respectively.

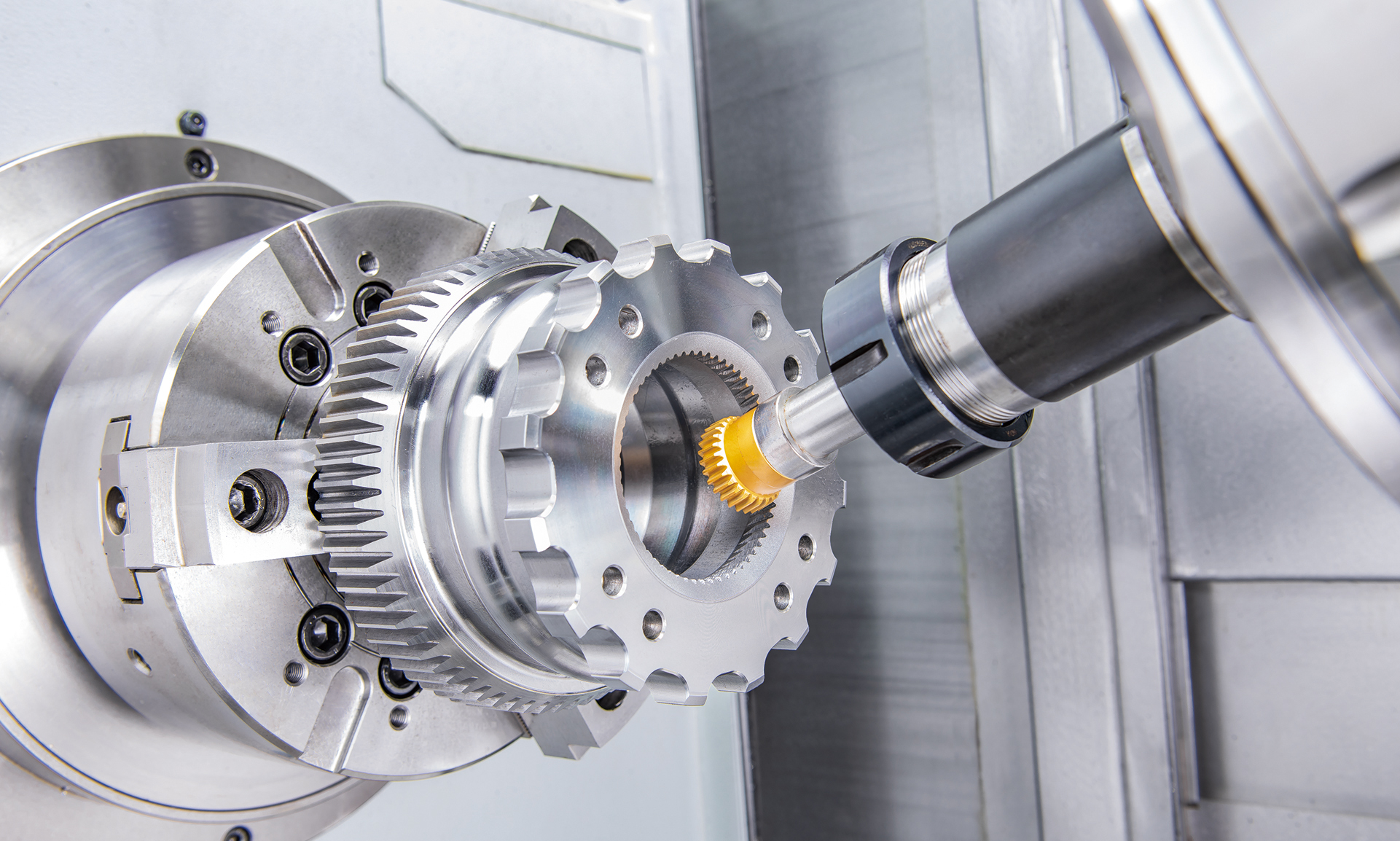

- The 9-station lower turret works with the tool spindle to perform high-precision balanced turning.

- The high-efficiency programmable servo tailstock, equipped with an MT#5 live center, provides stable support for long workpieces.

- Both the spindle, tool spindle and X1-axis ball screw are equipped with a cooling oil circulates design, effectively suppressing thermal displacement to ensure ultimate machining accuracy.

- Optional thermal compensation system.

Features

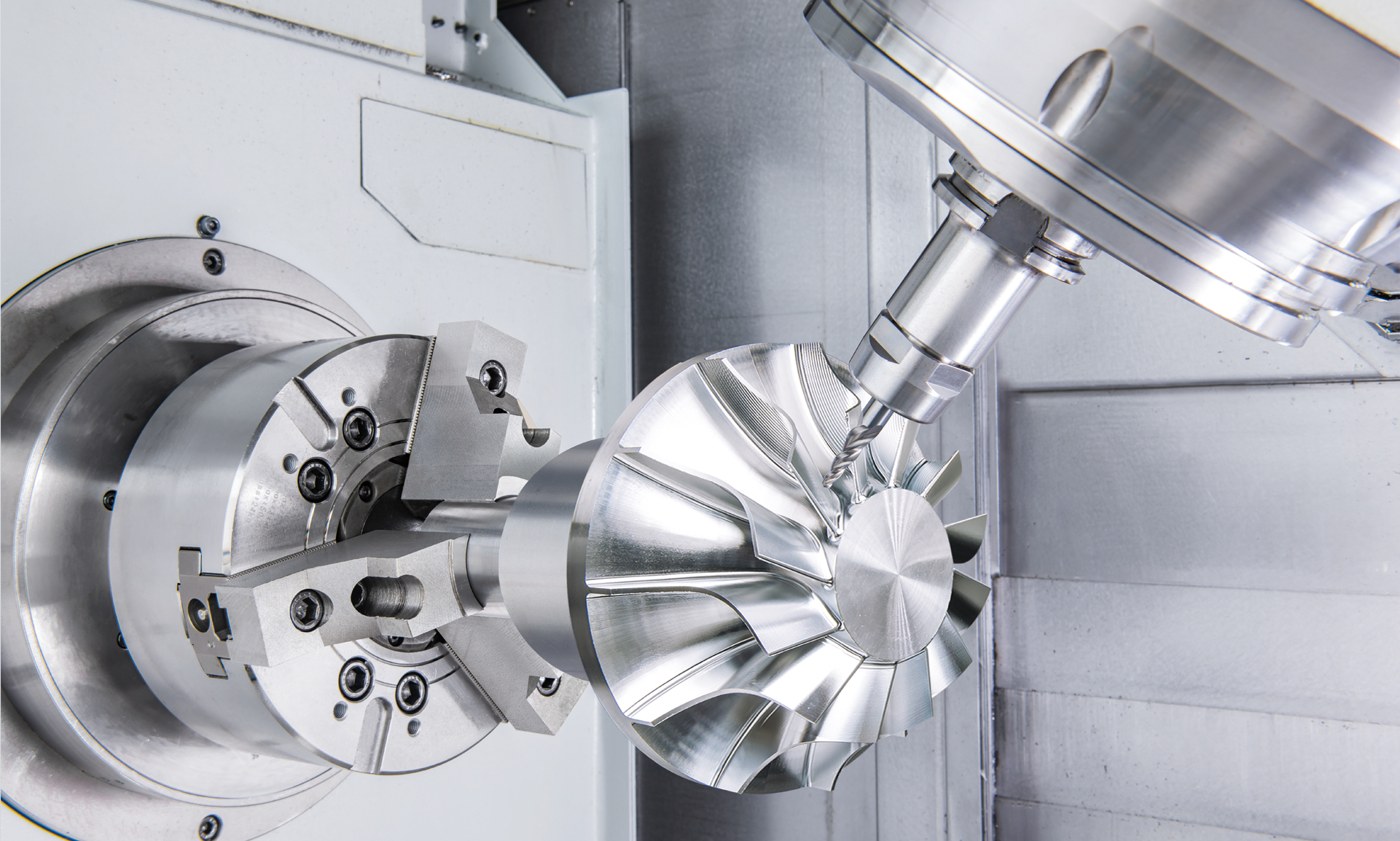

Tool Spindle Equipped with B-axis

High-reliability ATC System

Powerful Cutting Capability

Precision Enhancements

Model Variations

- Spindle 2

- Lower turret

- Spindle 2

- Lower turret

- Spindle 2

- Lower turret

spindle

Milling Spindle

- The built-in motor design can reduce the rotation vibration of the spindle, extend the life of the spindle, and ensure processing accuracy under long-term operation.

- The cooling circuit circulates around the spindle shaft and front bearing, and the temperature is precisely controlled by an independent cooler which can effectively reduce the thermal displacement of the spindle and ensure excellent machining accuracy.

B-axis

- The milling spindle comes with many features such as high speed, high horsepower, low interference, etc.; it can continuously index every 0.001° within the 240° B-axis travel range. Not only to perform heavy cutting on fixed angle, but also perform 5 axes simultaneous motion contour milling, with extremely flexible processing capabilities.

- High-rigidity roller cam drive design ensures high rotational accuracy and near-zero backlash (standard with full-closed loop rotary optical scales).

C-axis

- The C-axis is directly driven by the main spindle motor (Cs-axis), coupled with a high-resolution position encoder and disc brake system. This ensures precise and rapid positioning, with a minimum indexing increment of 0.001°, providing extremely high dynamic performance.

- The brake system adopts the design of 360° all-axial hydraulic brake and disc brake disc, which has the characteristics of high rigidity, heavy cutting resistance, and extremely high resistance to vulcanization.

ATC System

- The chain type magazine is combined with the design of the arm type ATC system, which has ample tool capacity, fast and reliable tool change, can significantly save non-cutting time, and can meet the processing needs of complex workpieces.

- Standard 40T ATC magazine. ( 80T or 120T magazines are optional ).

High Rigidity Lower Turret

- The servo indexing turret achieving 0.2 second indexing times for adjacent stations and 0.5 second for stations at the opposite end of the disk. Index movements are single step, without pauses, no matter how many stations are skipped.

Back Processing Capacity

- The spindle 2 adopts the same specification design as the spindle 1, which can provide the same powerful cutting ability on the front and back of the workpiece.

- The optional parts catcher or parts conveyor system can eliminate the burden of manual unloading to meet the needs of mass production.