GS-8000

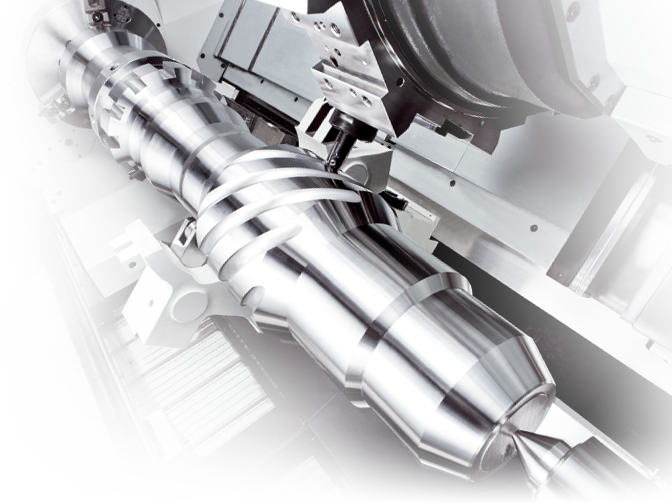

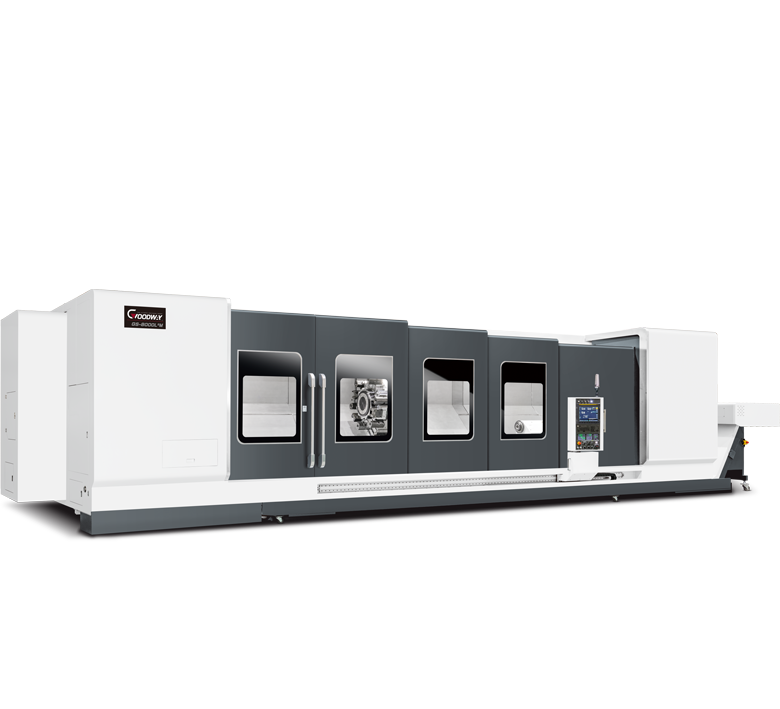

With leading technologies and high quality components, the GS-8000 series heavy duty CNC turning center combines a super rigidity box way bed with extra large diameter servo indexing turret and powerful geared spindle structure to provide you with efficient machining performance for large diameter and extra long work pieces. Meanwhile, with the optional live tooling turret and Y-axis, the GS-8000 series can easily accomplish multi-tasking operations for large and complex work pieces to fulfill various machining needs for today and tomorrow.

- The ultimate production solution designed specifically for machining extra-long and large-diameter workpieces.

- With a large Ø320 mm hole through spindle diameter and ±160 mm of Y-axis travel, the series offers the capacity and flexibility needed for oversized and complex workpieces machining tasks.

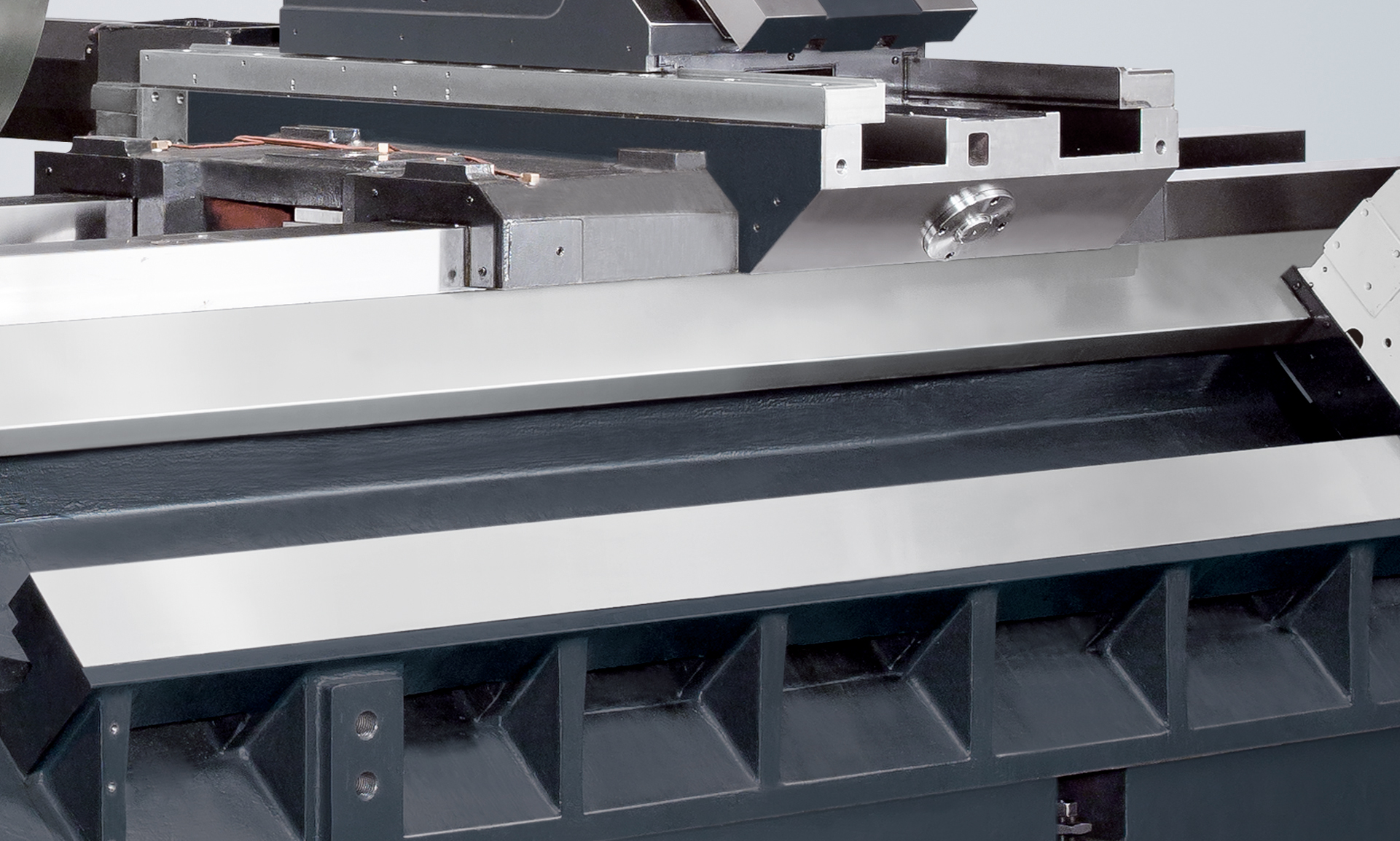

- X and Z axes feature over-sized box ways combined with a wide-span design.

- Constructed from high-quality cast iron, the low-center-of-gravity base delivers outstanding structural rigidity, ensuring stability and precision under heavy loads.

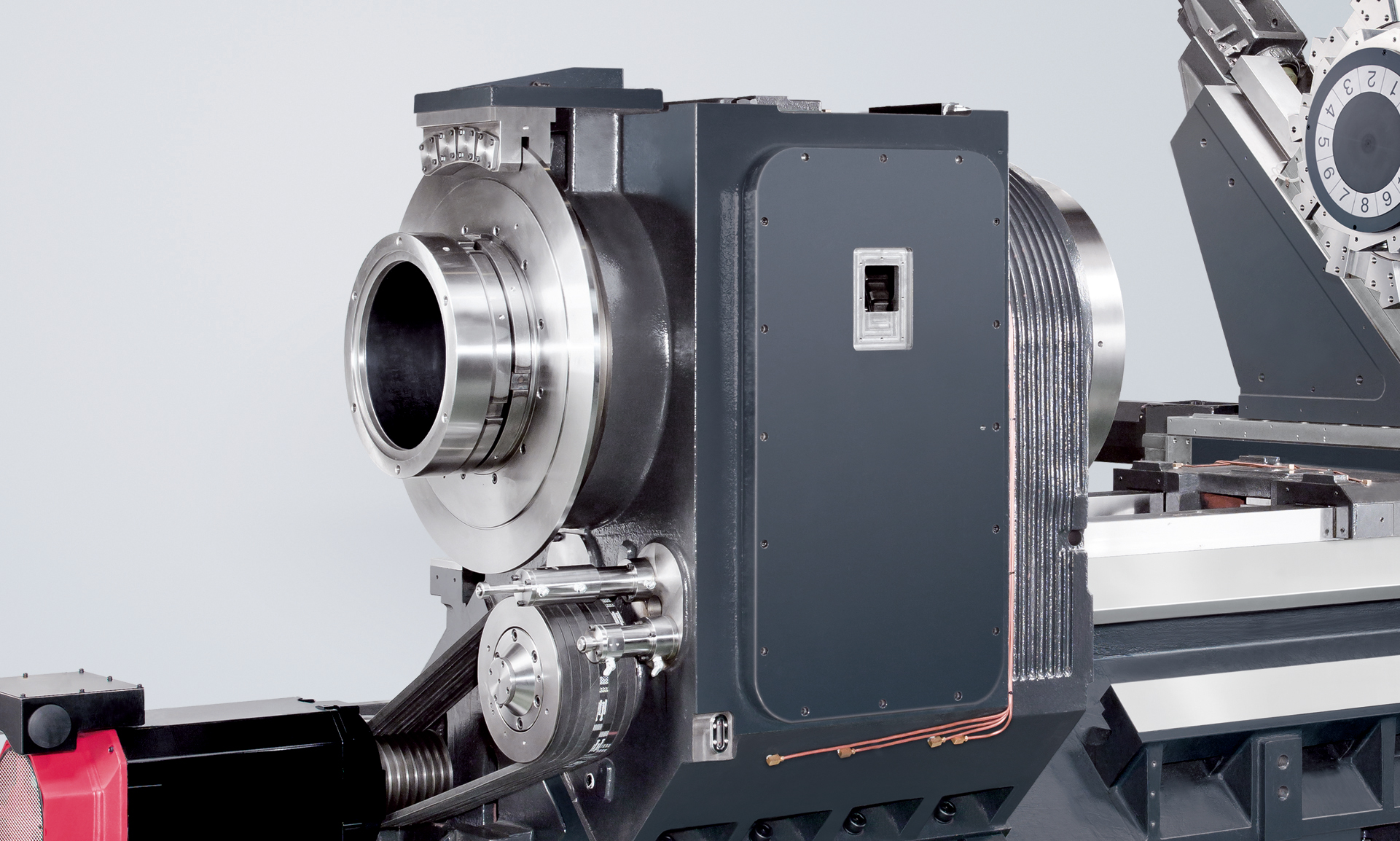

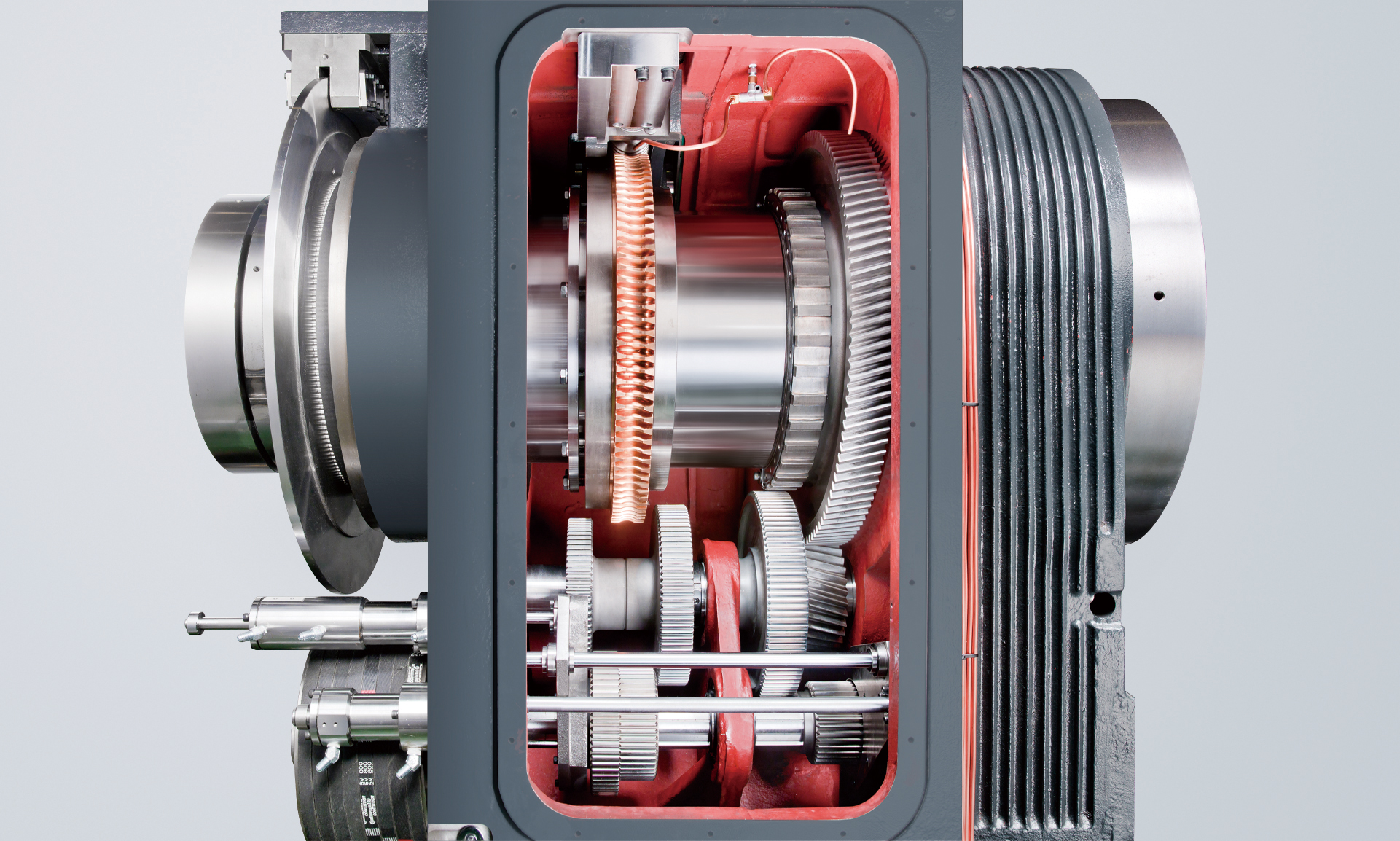

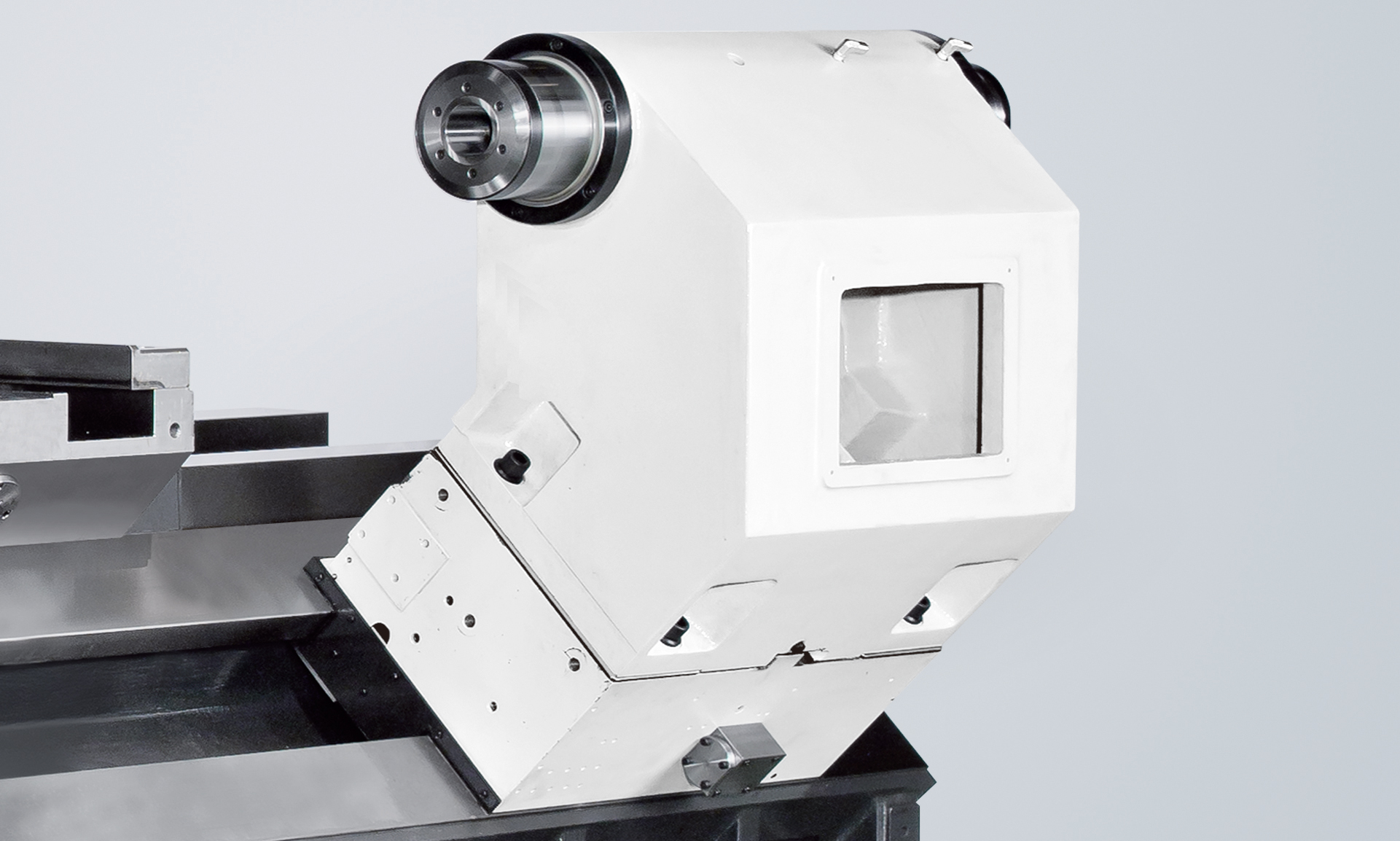

- Powered by a 45 kW spindle motor and a 3-speed gearbox, the spindle delivers an impressive maximum torque of 7,100 Nm, providing the strength and performance needed for the most demanding cutting applications.

- 12-station servo-indexed turret with high rigidity and extra-large turret disk diameter.

- High-efficiency programmable tailstock with MT#6 built-in rotary quill.

- The automatic self-centering steady rest allows for a maximum workpiece outer diameter of Ø520 mm.

- Live tools are driven by a 9 kW spindle motor, delivering ample power with high torque output.

- The largest Y-axis travel in its class enables effortless machining of large and complex workpieces.

Features

High Rigidity Structure

The Ultimate Machining Power

User-friendly Operation

Integrated Machining

Model Variations

M

- Live tooling turret

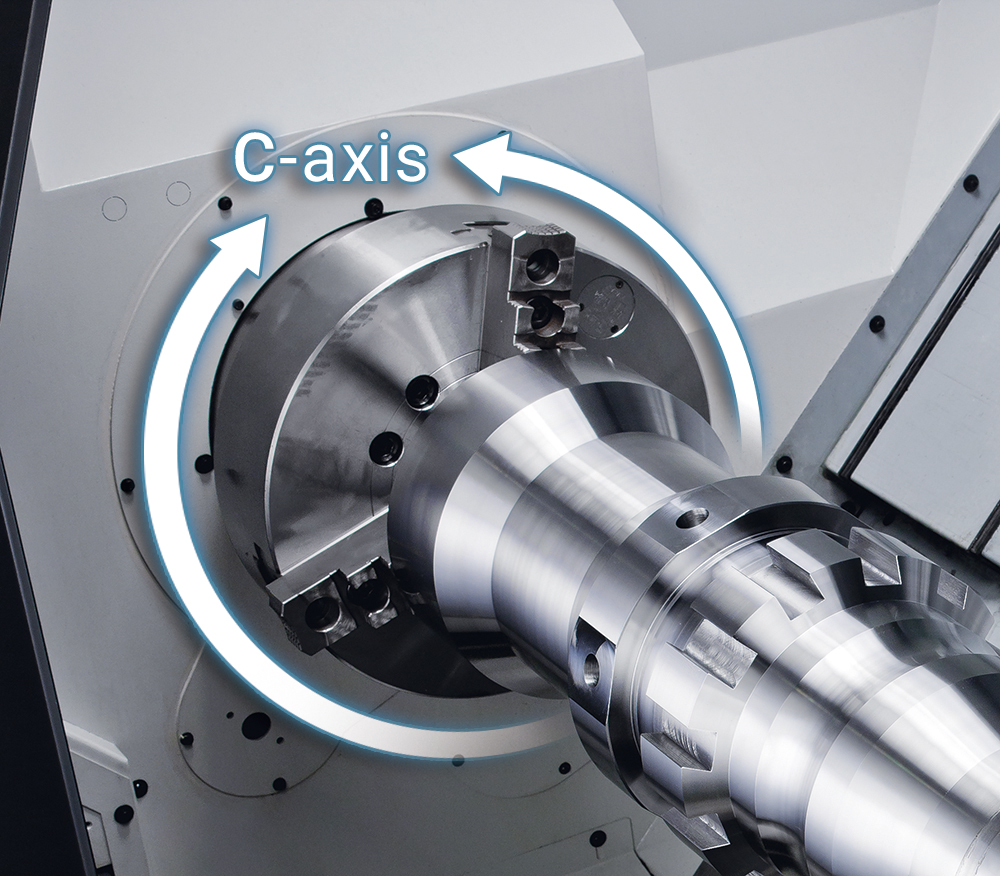

- C-axis

- Y-axis

Y

- Live tooling turret

- C-axis

- Y-axis

Heavy-duty spindle headstock

3-speed, high-torque gearbox

High-rigidity box way design

Programmable tailstock and MT#6 built-in rotary quill

Live tooling turret

C-axis

Live Tooling Turret

- Featuring a high-torque 9 kW (30 min.) dual-wound spindle motor, the live tooling turret offers cutting capabilities that outperform standard 40-taper machining centers, enabling effortless execution of challenging cutting tasks.

- The 12-station live tooling turret offers 12 stations available for live tooling, live tools rotate in working position only to reduce power loss and heat.

C-axis

- The Cf-axis and disk brake system provide the most rigid and powerful type of C-axis control on the market today.

- Working with the live tooling turret, the Cf-axis and disk brake system enables the machine to perform multiple tasks, such as drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations, resembling a 4th-axis rotary table on a machining center.

- With the FANUC servo motor generating an ultra high resolution of 1,000,000 pulses per spindle rotation and high torque, machined surface finishes are much superior than Cs-axis ( driven by spindle motor ) equipped machines. Plus, dynamic accuracy is within ± 0.02˚ even under heavy cutting loads.

Y-axis Control Function

- An extended Y-axis travel of 320 mm accommodates the machining requirements of large and complex components in industries such as aerospace, shipbuilding, and energy equipment.

- The Y-axis guideway also features a high-rigidity box way design.