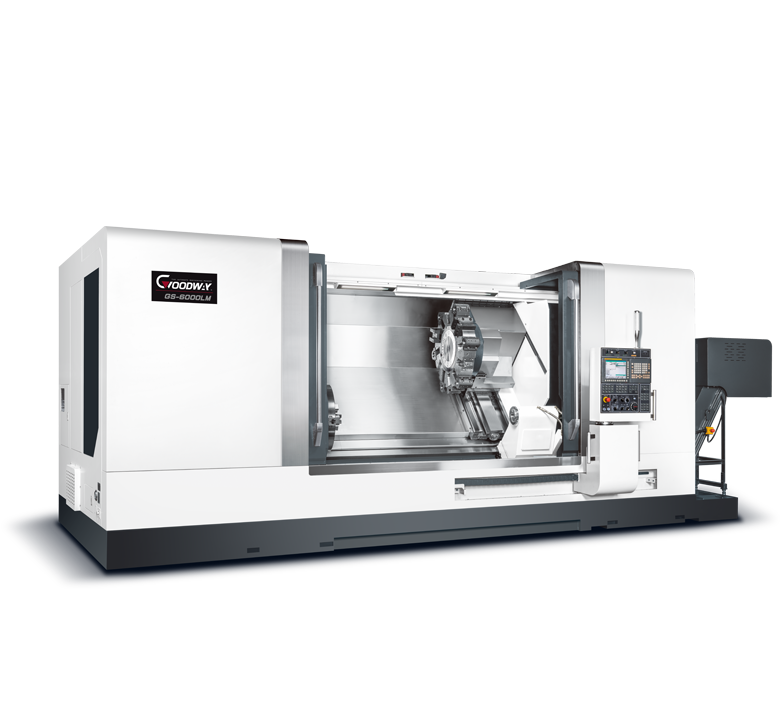

GS-6000

With leading technologies and high quality components, the GS-6000 series maximum performance turning center combines a super rigidity box way bed with super large diameter servo indexing turret and 2-step gear spindle structure that provides great horse power, high speed indexing, and heavy-duty cutting capabilities. The GS-6000 series is available with optional L3 model, with up to 3,300 mm turning length and “M” model, with live tooling turret and C-axis, which enables higher cutting flexibility and multi-tasking power to meet most of today and tomorrow's turning applications demands.

- The best production solution for long and large-diameter workpieces.

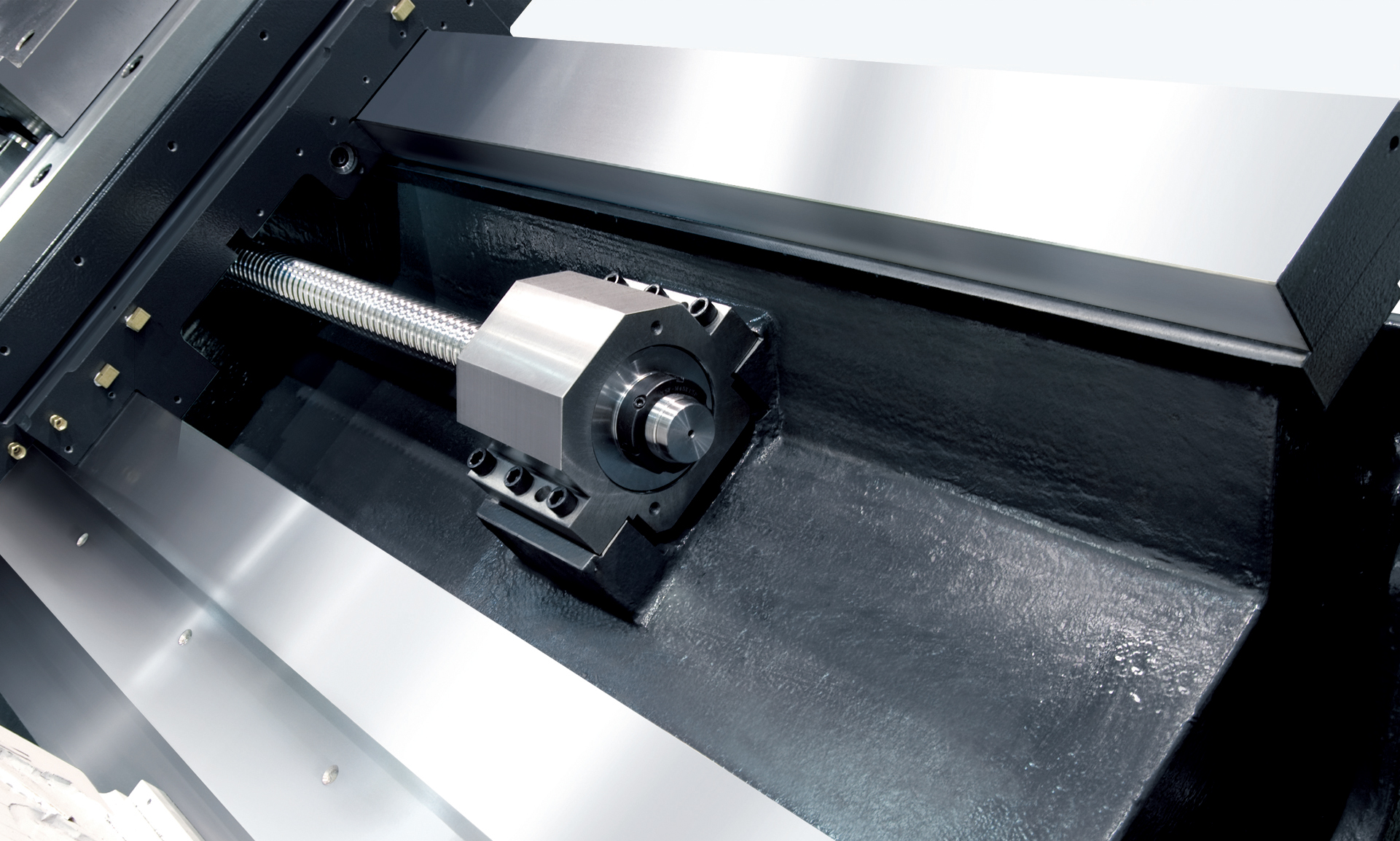

- Ultra-high rigidity slant bed with extreme cutting performance.

- X and Z axes feature over-sized box ways combined with a wide-span design.

- The low center of gravity 45° true slant bed ensures maximum structural rigidity.

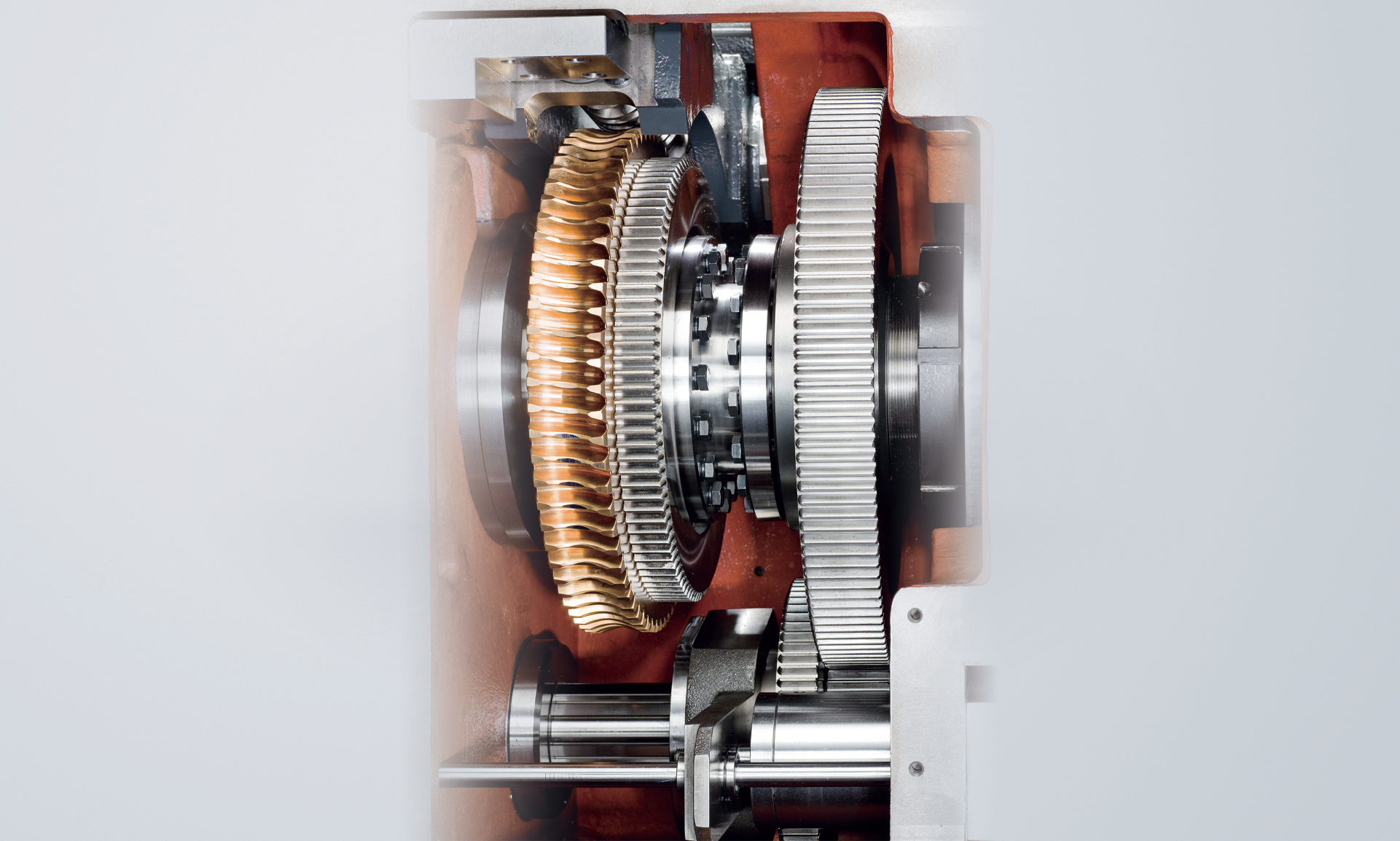

- The 37 kW spindle motor drives a 2-step gearbox, with a maximum spindle torque output of 4,300 Nm.

- 12-station servo-indexed turret with high rigidity and extra-large turret disk diameter.

- High-efficiency programmable tailstock.

- High-rigidity manual steady rest / Automatic self-centering steady rest.

- Live tools are driven by a 9 kW spindle motor, delivering ample power with high torque output.

Features

High Rigidity Structure

The Ultimate Machining Power

User-friendly Operation

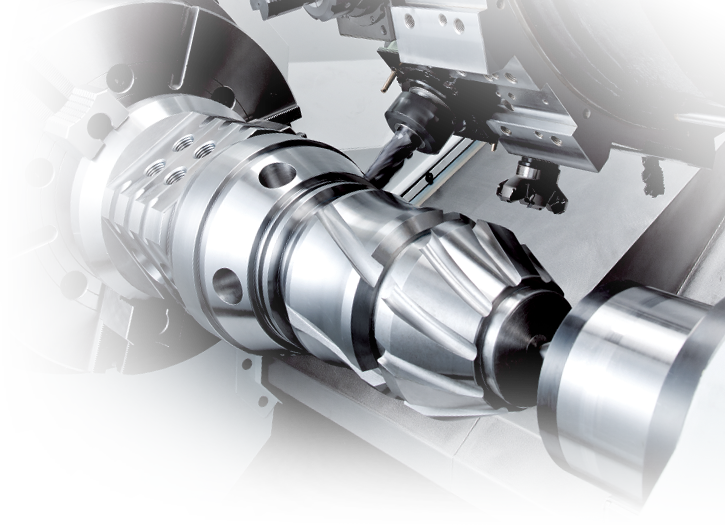

Integrated Machining

Model Variations

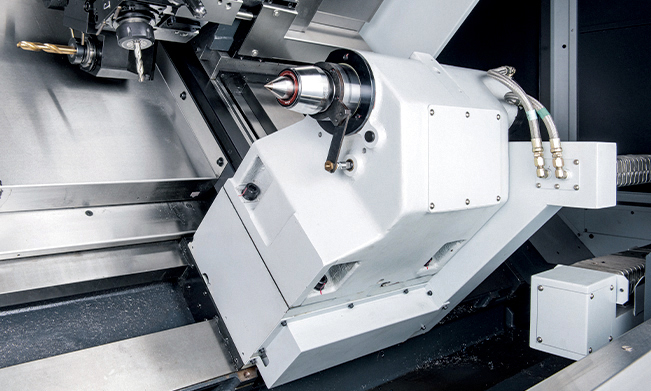

- Live tooling turret

- C-axis

Live Tooling Turret

- Featuring a high-torque 9 kW (30 min.) dual-wound spindle motor, the live tooling turret offers cutting capabilities that outperform standard 40-taper machining centers, enabling effortless execution of challenging cutting tasks.

- The 12-station live tooling turret offers 12 stations available for live tooling, live tools rotate in working position only to reduce power loss and heat.

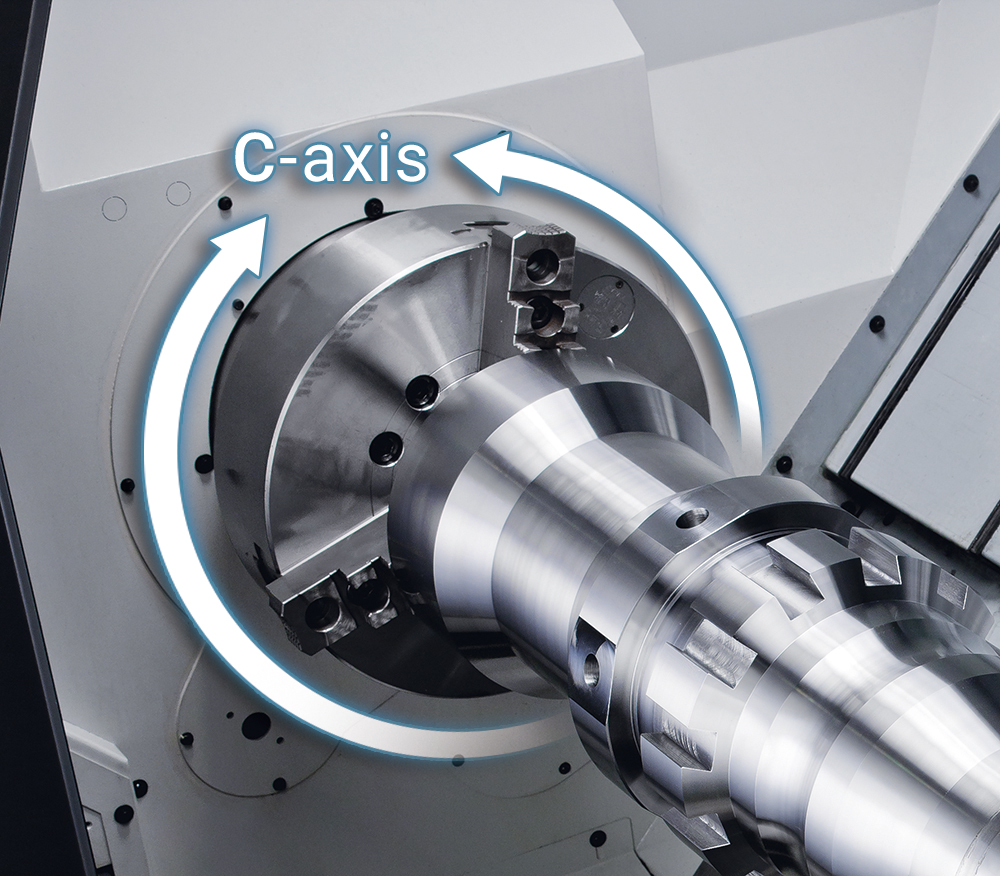

C-axis

- Working with the live tooling turret, the Cf-axis and disk brake system enables the machine to perform multiple tasks, such as drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations, resembling a 4th-axis rotary table on a machining center.

- With the FANUC servo motor generating an ultra high resolution of 1,000,000 pulses per spindle rotation and high torque, machined surface finishes are much superior than Cs-axis ( driven by spindle motor ) equipped machines. Plus, dynamic accuracy is within ± 0.02˚ even under heavy cutting loads.