GS-4000

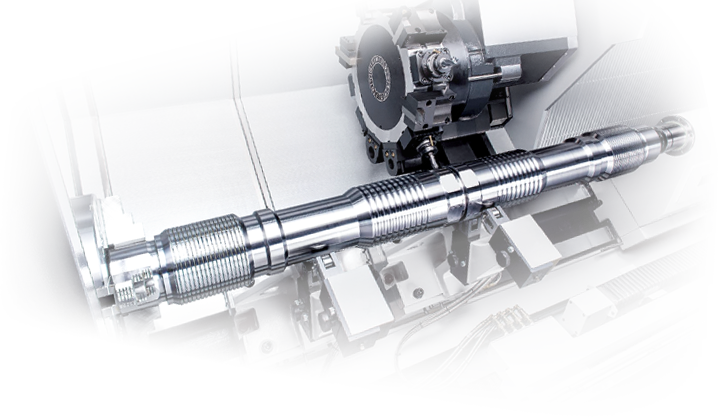

Packed with the latest machine tool technologies and powerful cutting capabilities, the GOODWAY GS-4000 series CNC turning centers are built on a foundation of four bed lengths and two spindle sizes. Featuring a high-rigidity box-way structure, a high-torque two-speed gearbox, and a large-diameter turret, this series is engineered for heavy-duty cutting and a wide machining range.

With optional live tooling, sub-spindle, and Y-axis configurations, the GS-4000 series are able to complete turning, milling, drilling and tapping of both ends of a workpiece in one single machine. This versatility makes it the ideal solution to meet your complex machining needs, today and into the future.

- A versatile machine capable of handling a wide range of workpiece sizes and machining conditions.

- Comprehensive turning and milling capabilities with a live tooling turret, Y-axis, and sub-spindle.

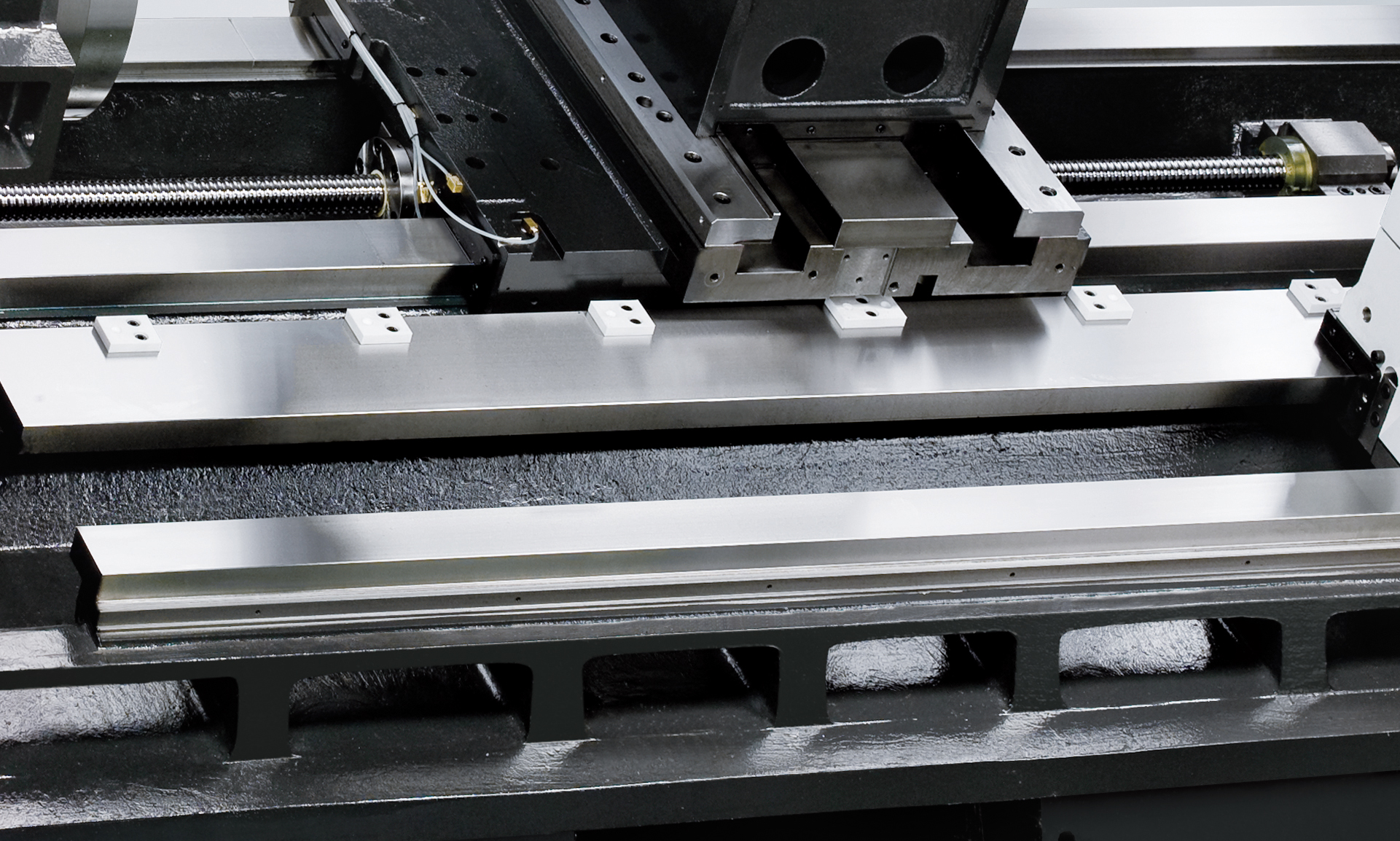

- The X/Z axes utilize large hardened box ways with a wide span design.

- The low center of gravity 30° slant bed design ensures maximum structural rigidity.

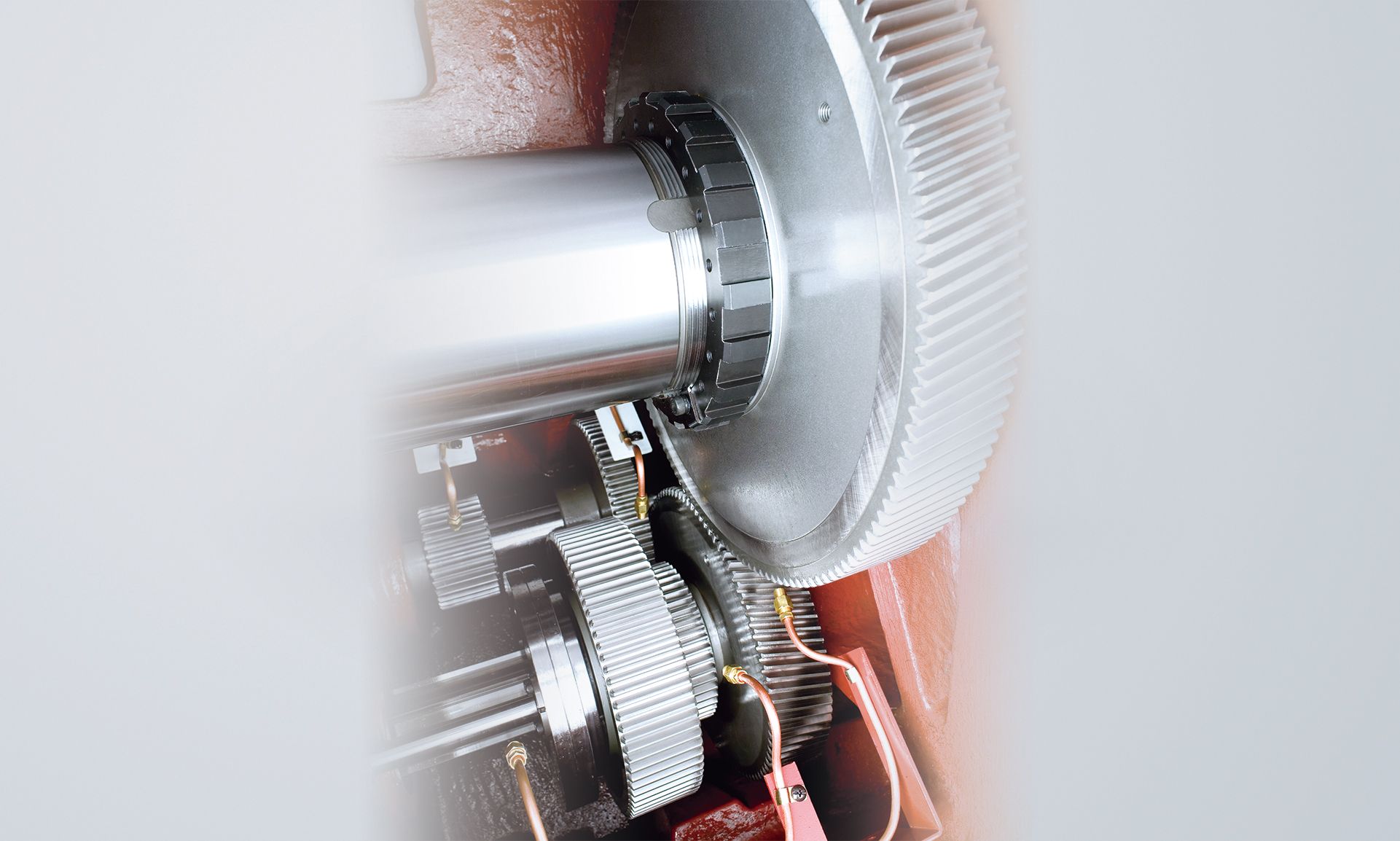

- The 37 kW spindle motor drives a 2-speed gearbox, with a maximum spindle torque output of 2,900 Nm.

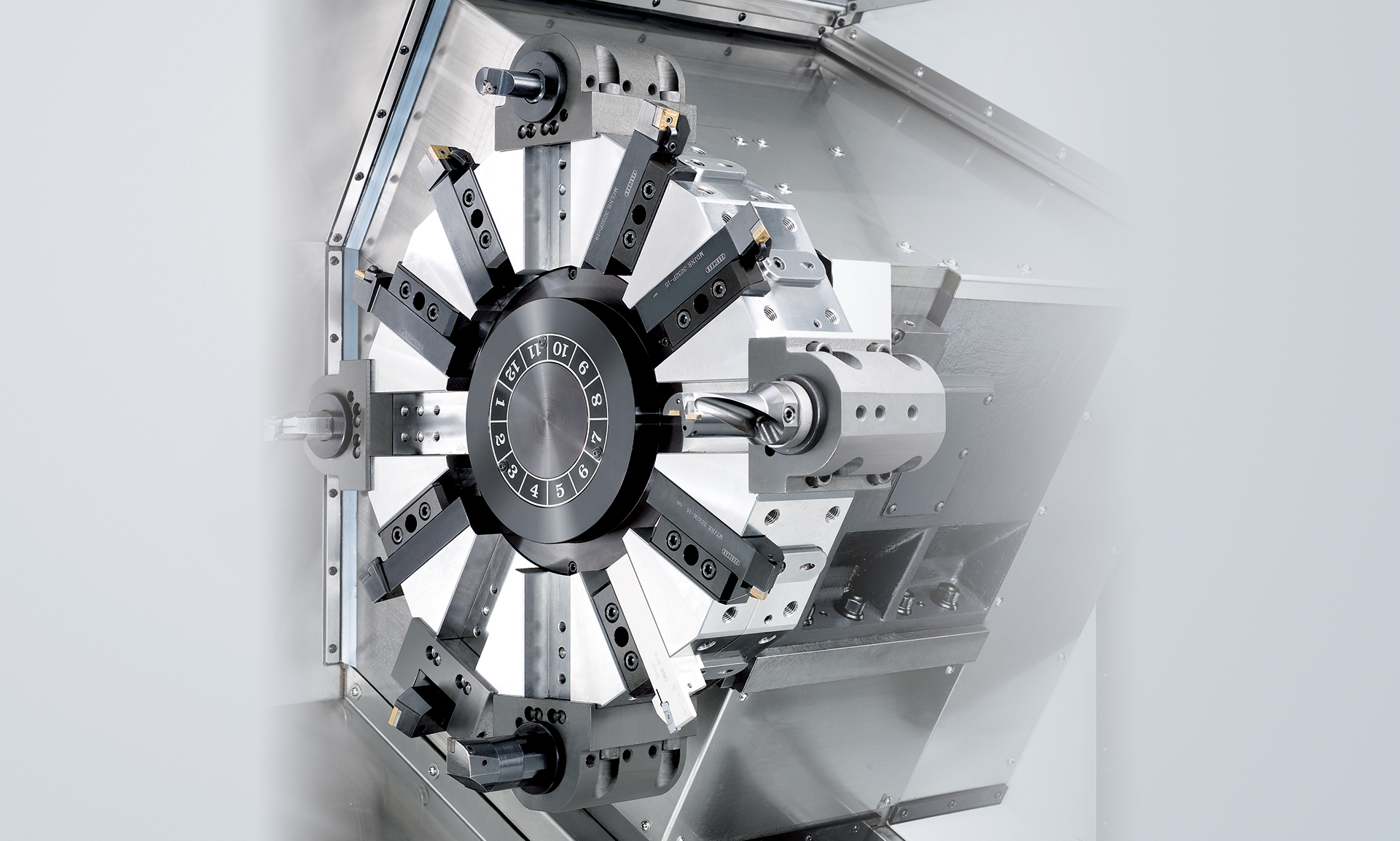

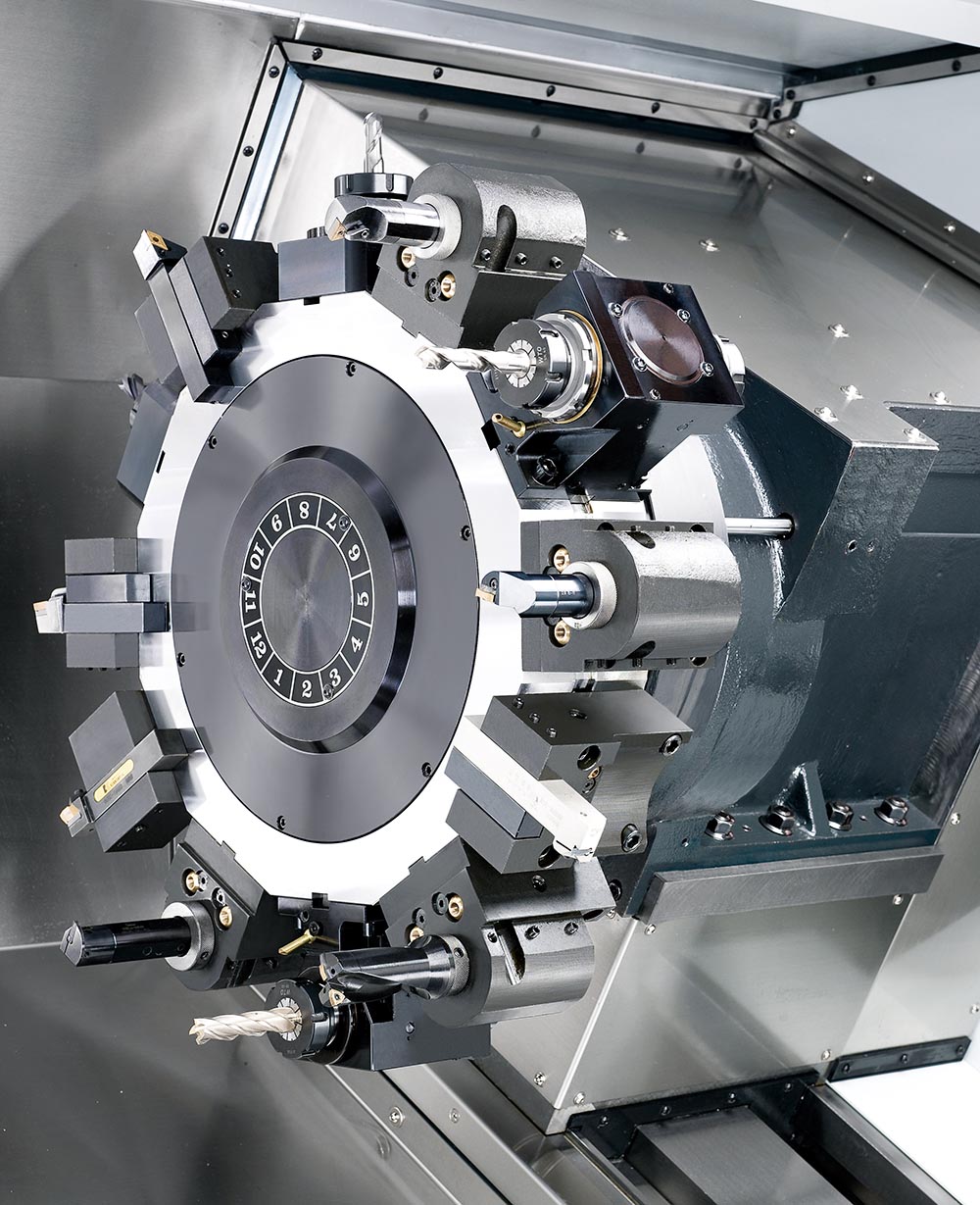

- 12-station servo-indexed turret with high rigidity and extra-large turret disk diameter.

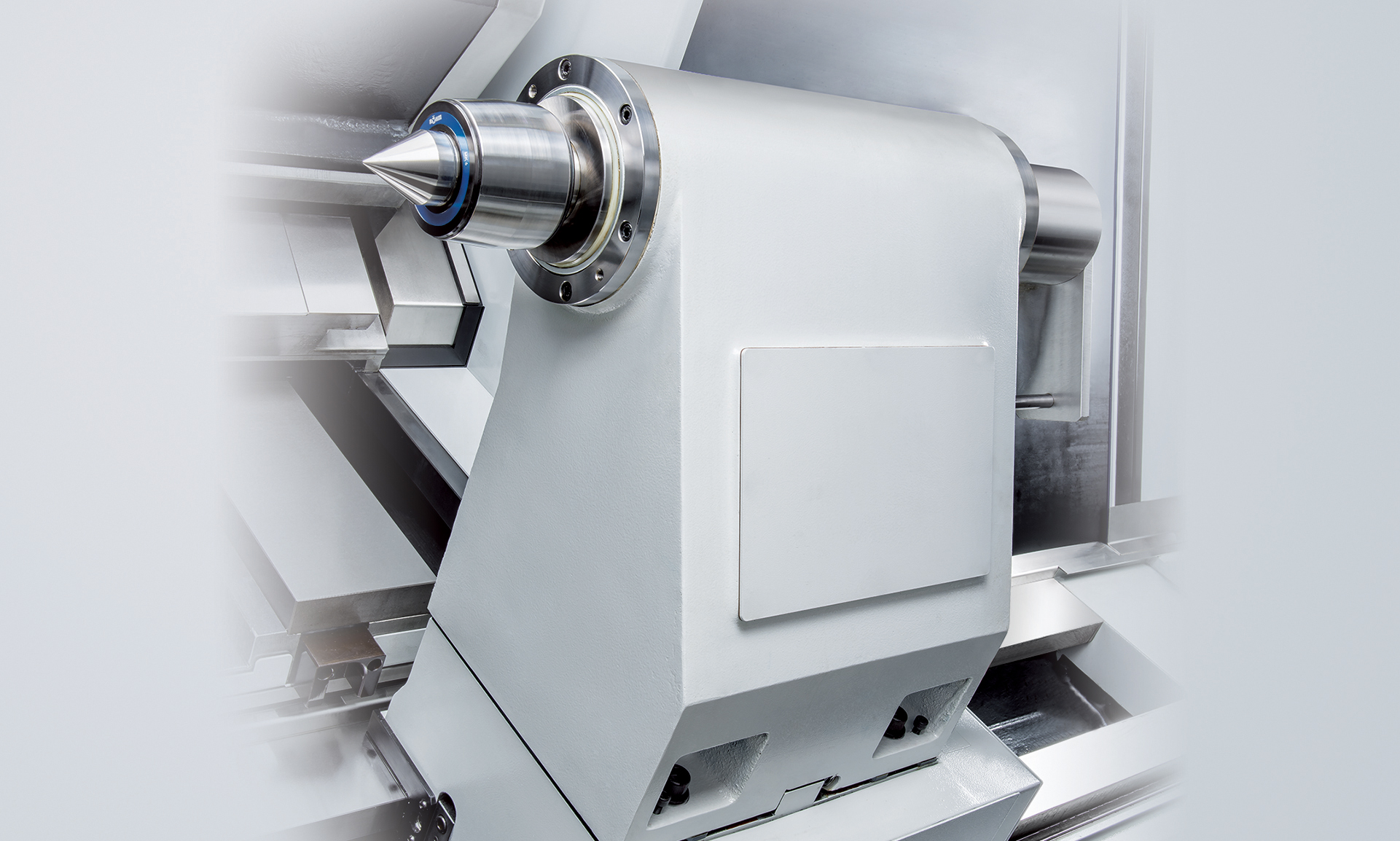

- High-efficiency programmable tailstock / High-thrust servo tailstock.

- High-rigidity manual steady rest / Automatic self-centering steady rest.

- Live tooling is driven by a 7.5 kW spindle motor, delivering ample power output with high torque.

- The sub-spindle features an 8" chuck and is driven by an 18.5 kW built-in motor, reaching a maximum speed of 4,800 rpm.

- Y-axis control function with a travel of ±60 mm enhances the machining capability for complex workpieces.

Features

High Rigidity Structure

The Ultimate Machining Power

User-friendly Operation

Integrated Machining

Model Variations

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

Live Tooling Turret

- Live tooling and C-axis control capabilities on the GS-4000 series allow the machine to perform multiple tasks on a work-piece, such as turning, milling, drilling, and tapping. It eliminates manpower and cycle time while reducing in loss of accuracy, which will occur if the part is moved from machine to machine.

- The live tooling turret is driven by a 7.5 kW (30 min.) spindle motor combined with a reduction mechanism, delivering ample torque output to effortlessly handle demanding milling, drilling, and tapping operations.

- The 12-station live tooling turret offers 12 stations available for live tooling, live tools rotate in working position only to reduce power loss and heat.

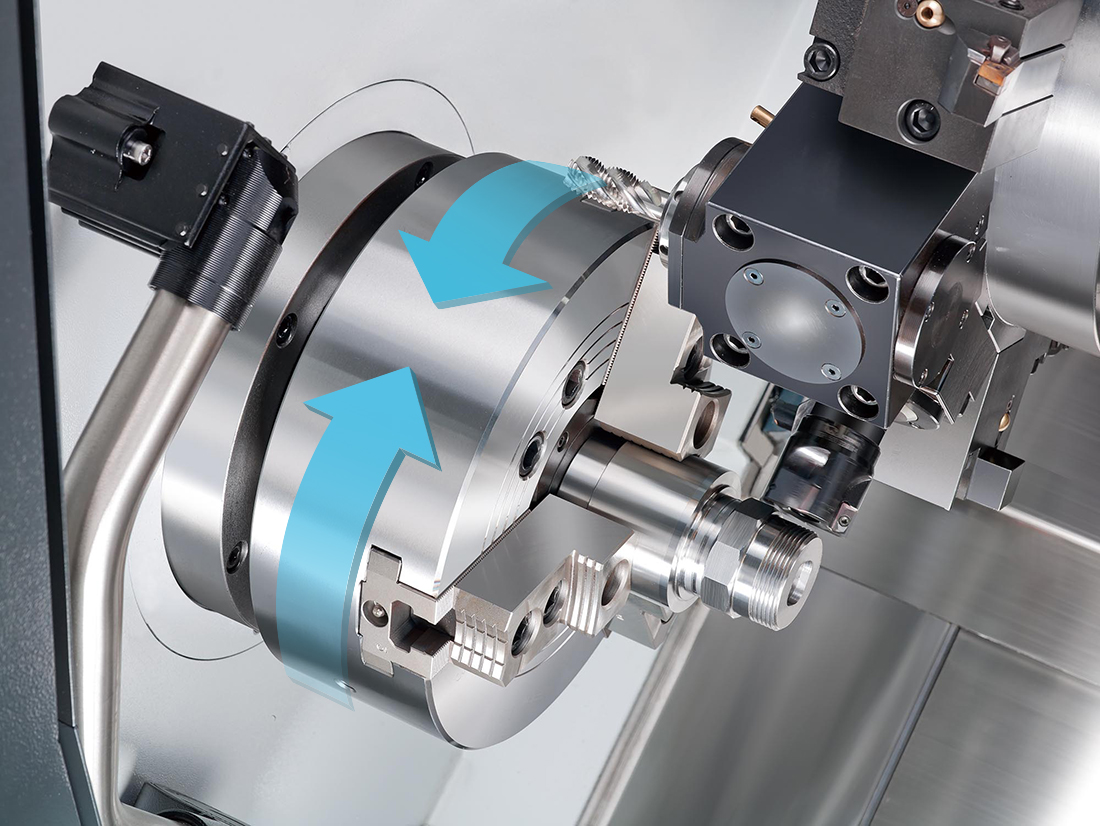

C-axis

- With Cs-axis contouring control, the C-axis indexing is driven by FANUC spindle motor with disc brake system and high resolution encoder. It can execute linear interpolation and circular interpolation with other feeding axes to obtain the required precise contour curve.

- With Cs-axis extremely high dynamic performance, spindle mode can directly switch to C-axis servo mode. The fast indexing speed ( 33 rpm/min. ) and min. indexing angle is 0.001°, which can effectively meet the machining need on GS-4000 series.

Back Processing Capacity

- The optional sub-spindle enhances productivity with efficient back-end machining capabilities. Powered by an 18.5 kW ( 15 min. ) built-in FANUC motor and equipped with an 8" chuck, the sub-spindle features an integrated parts ejector. This allows finished components to be automatically released and dropped into the parts catcher.

- The B-axis guideway for the sub-spindle’s movement utilizes a high-precision roller-type linear guideway design. This combines the high rigidity of box ways with the rapid movement of linear guideways.

Y-axis Control Function

- Y-axis control further enhances multi-tasking live tooling capabilities and improves various machining precision. High precision grooving and X-axis off-center drilling are enabled.