GS-2000 / GS-3000

The GS-2000 / GS-3000 Series offers a maximum of 8 standard specifications, which includes 2 bed lengths and 4 bar capacities. With high power spindle, high speed servo turret, and high-rigidity structural design, this series delivers a significant performance increase over previous models.

Additionally, the GS-2000 / GS-3000 series can be equipped with an optional precision built-in type spindle, high torque geared spindle, or a live tooling turret, Y-axis and sub-spindle which can accomplish multi-tasking applications. With the perfect quality and complete tasking capabilities, the GS-2000 / GS-3000 series can easily various needs of today and tomorrow.

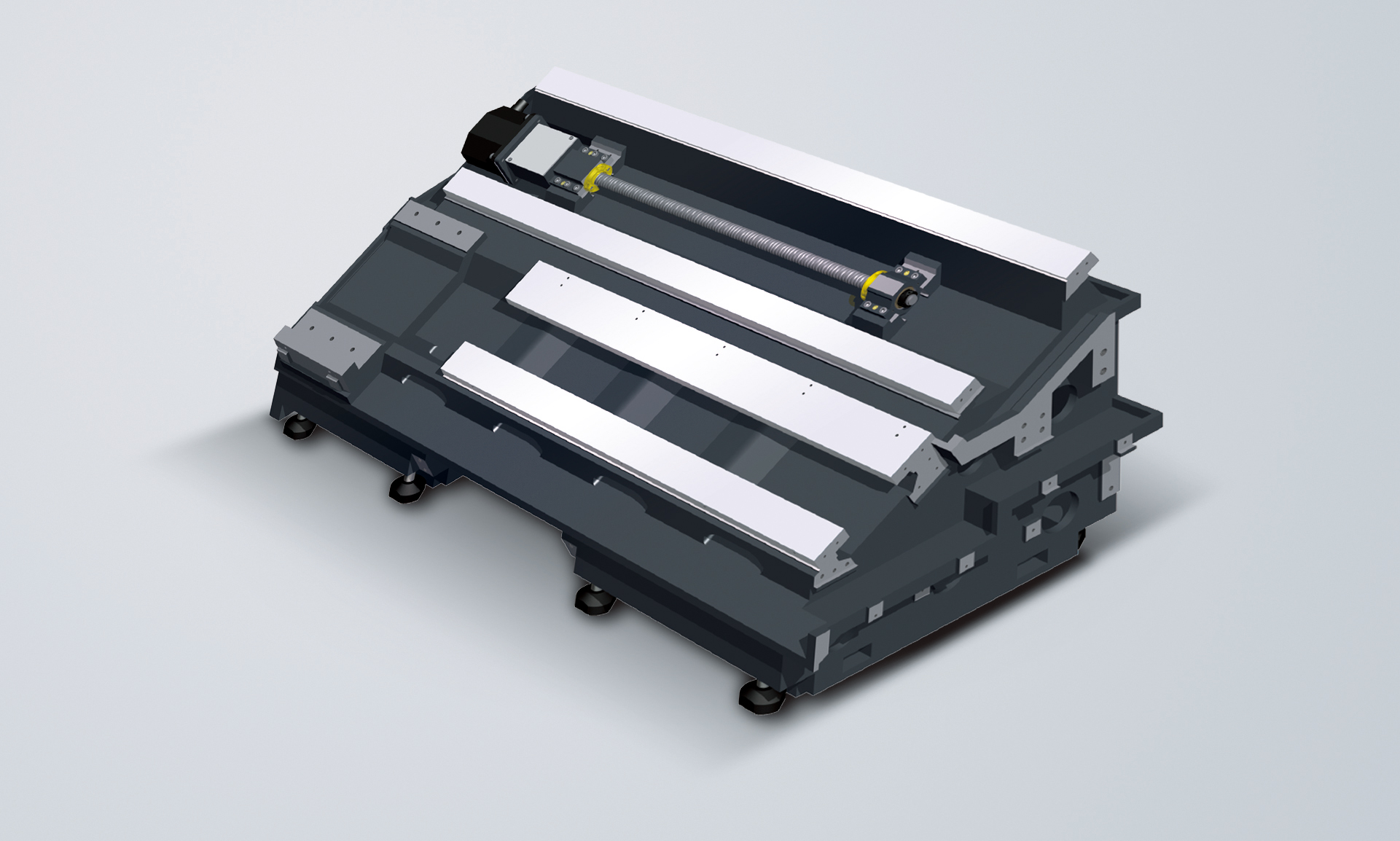

- Ultra-high rigidity slant bed with extreme cutting performance.

- A total of 8 basic machine configurations, with 2 bed lengths and 4 bar capacities.

- The X/Z axes utilize large hardened box ways with a wide span design.

- The low center of gravity 30° slant bed design ensures maximum structural rigidity.

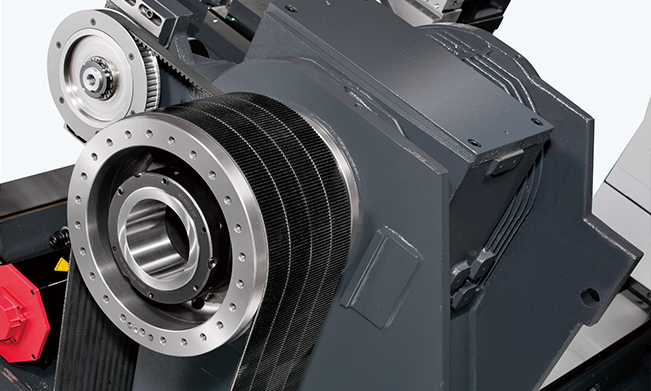

- Gear-driven, built-in, or belt-driven spindles can be selected according to requirements.

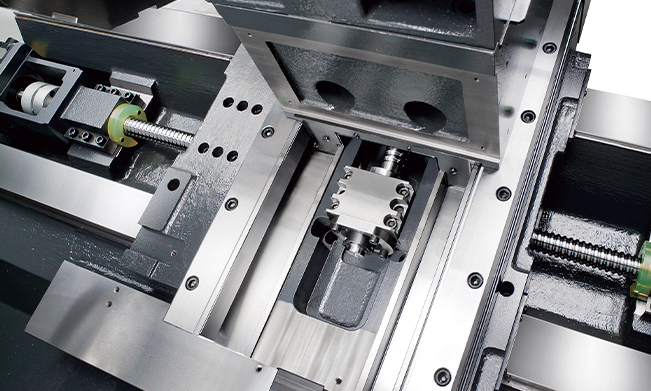

- Heavy-duty 12-station servo indexing turret design; opposing tool change takes only 0.8 seconds.

- High-efficiency programmable tailstock / Powerful servo tailstock.

- High-rigidity manual steady rest / Automatic self-centering steady rest.

- With a live tooling spindle speed of 5,000 rpm, it can easily handle various machining tasks such as milling, drilling, and tapping.

- Sub-spindle equipped with a 6" (GS-2000 series) / 8" (GS-3000 series) hydraulic chuck.

- Y-axis control with a travel of ±50 mm enhances the machining capability for complex workpieces.

Features

High Rigidity Structure

The Ultimate Machining Power

User-friendly Operation

Integrated Machining

Model Variations

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

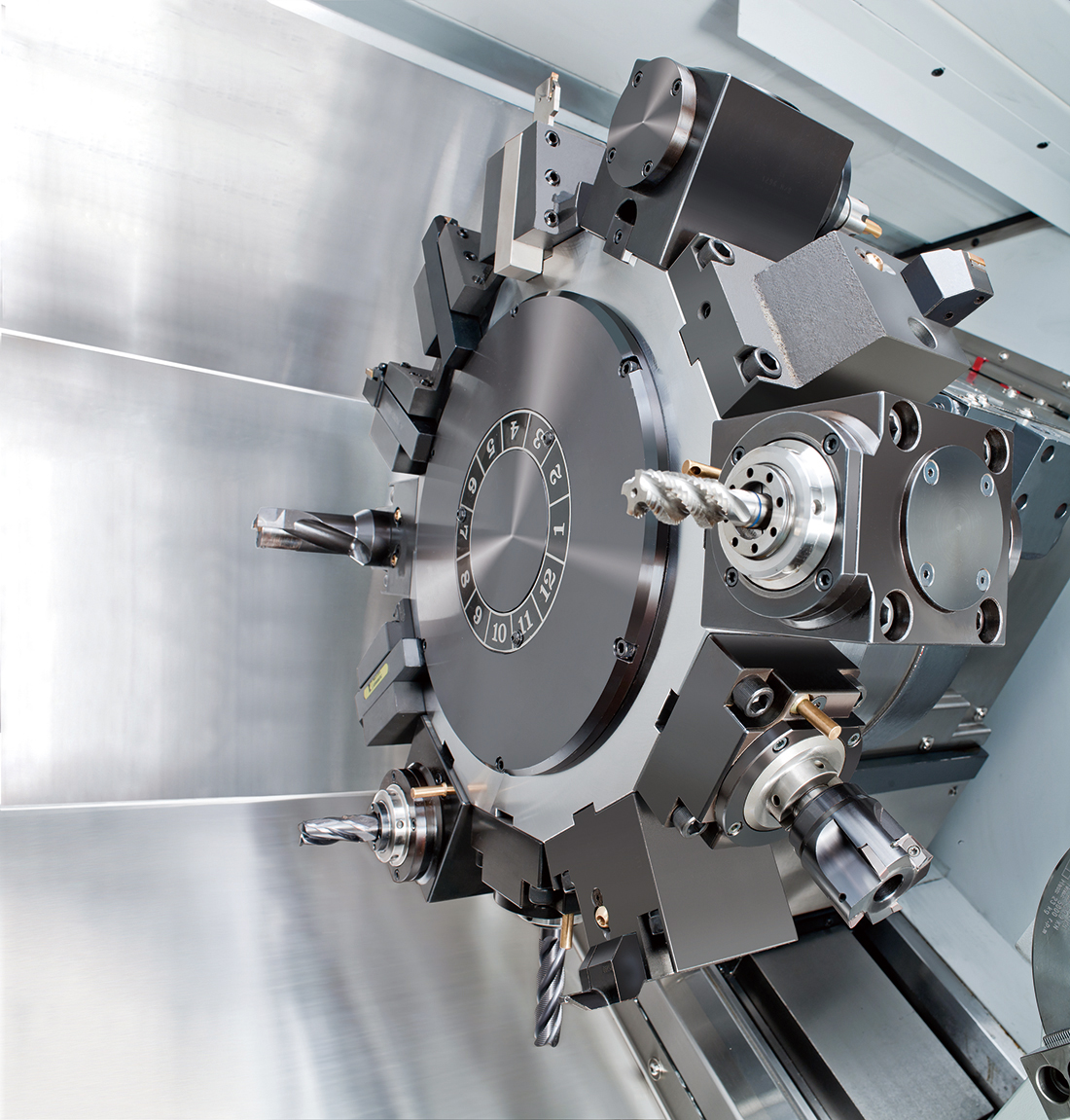

Live Tooling Turret

- Live tooling and C-axis control capabilities on the GS-2000 or GS-3000 series allows the machine to perform multiple tasks on a work-piece, such as turning, milling, drilling and tapping. It eliminates manpower and cycle time, while reducing accuracy lost, which will occur if the part is moved from machine to machine.

- The live tooling is driven by a 4.5 kW spindle motor with a transmission mechanism, providing ample horsepower for various demanding tasks such as milling, drilling, and tapping.

- The 12-station live tooling turret offers 12 stations available for live tooling, live tools rotate in working position only to reduce power loss and heat.

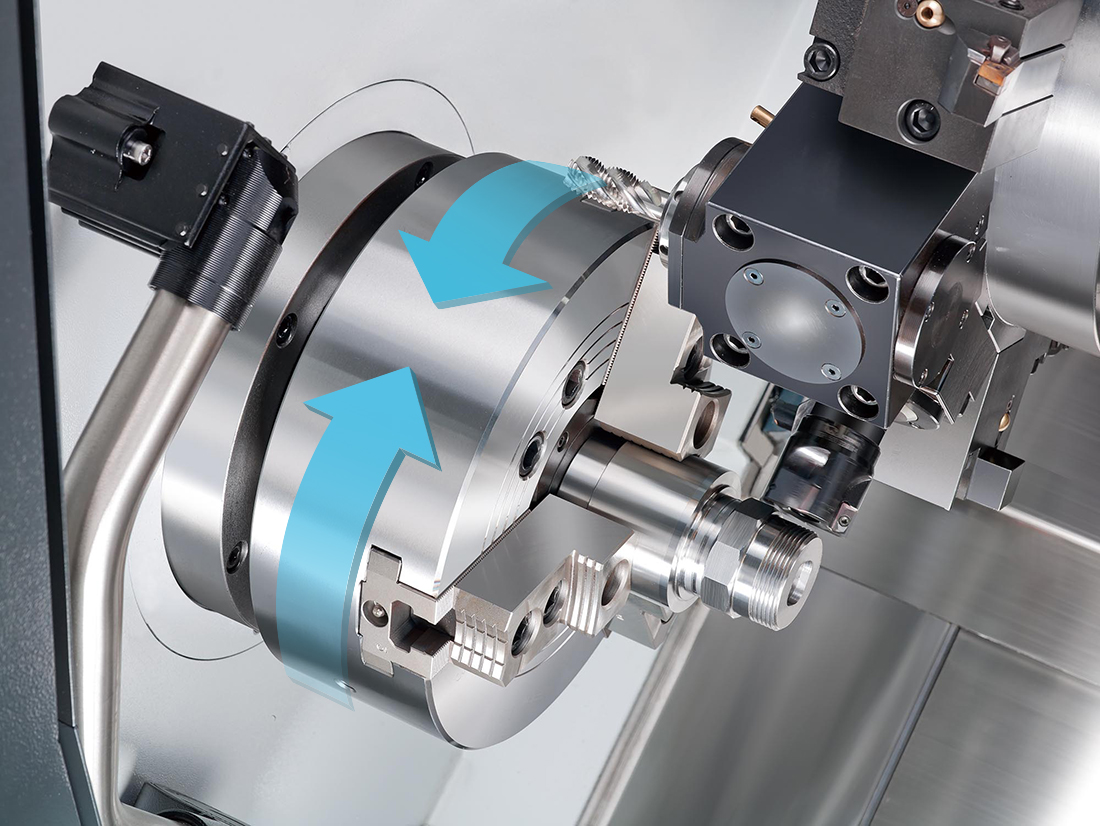

C-axis

- The Cf-axis and disk brake system available on the GS-2000 / GS-3000 series provides the most rigid and powerful type of C-axis on the market today.

- Working with the live tooling turret, the Cf-axis and disk brake system enables the machine to perform multiple tasks, such as drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations, resembling a 4th-axis rotary table on a machining center.

- With the FANUC servo motor generating an ultra high resolution of 120 million pulses per spindle rotation and 480 Nm of torque ( cont. ), machined surface finishes can reach to a higher accuracy level. Plus, dynamic accuracy is within ± 0.02°.

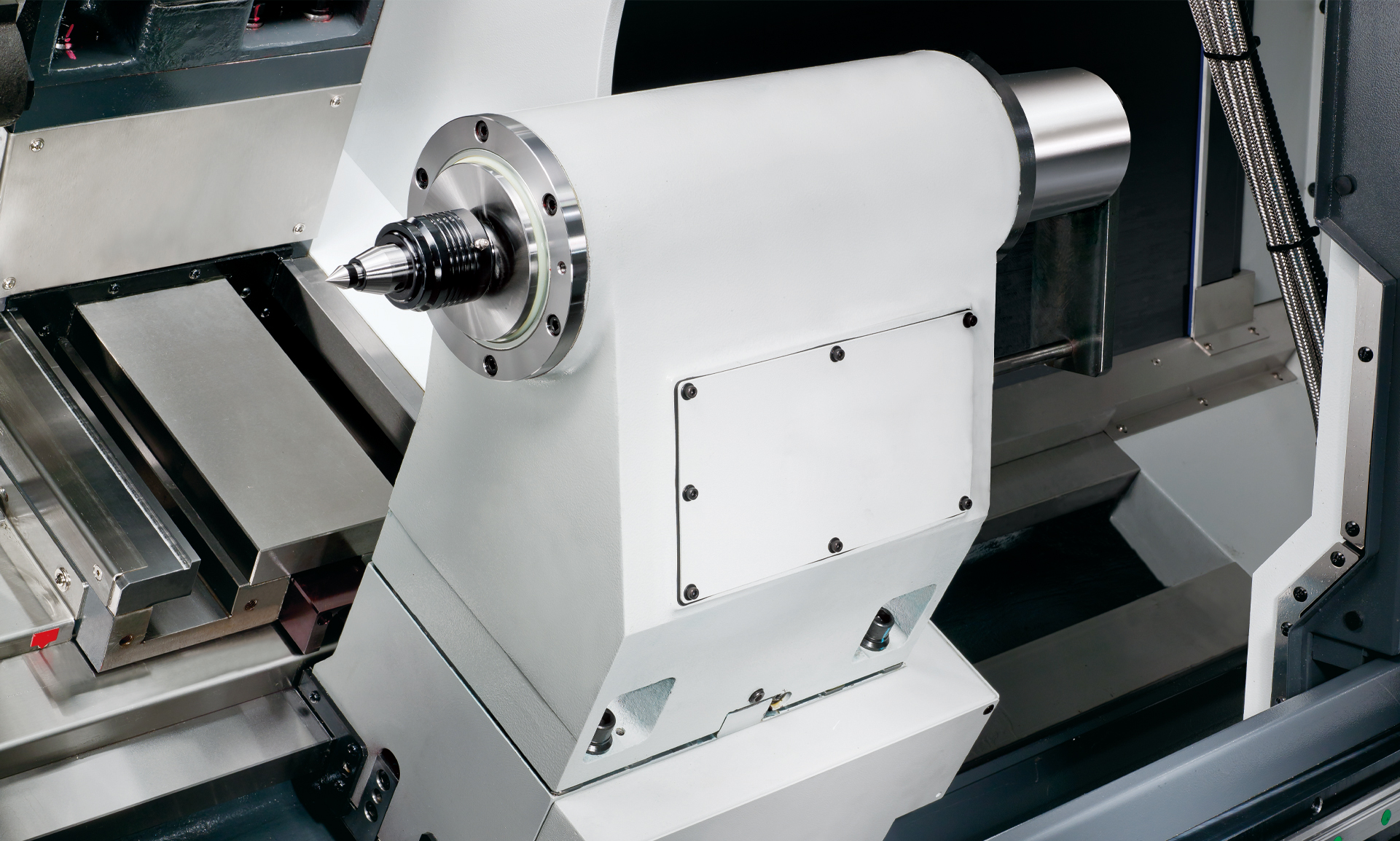

Rear-end Machining

- With the optional sub-spindle, the working process is done-in-one from input to output, without having to manually flip over the work-piece, thus increasing productivity and machining accuracy.

- The B-axis movement of the sub-spindle is adopted with roller type linear guideway design, to provide super rigidity, precision and fast movement ( 30 m/min. ) performance.

- The sub-spindle can also be equipped with the C-axis function ( same as the main spindle ), to allow the contour positioning accuracy reach up to 0.001°. It can also accomplish back-end milling, drilling and tapping applications when combined with a live tooling turret.

Y-axis Control Function

- Y-axis control further enhances multi-tasking live tooling capabilities and improves various machining precision. High precision grooving and X-axis o off-center drilling are enabled.