GS-200

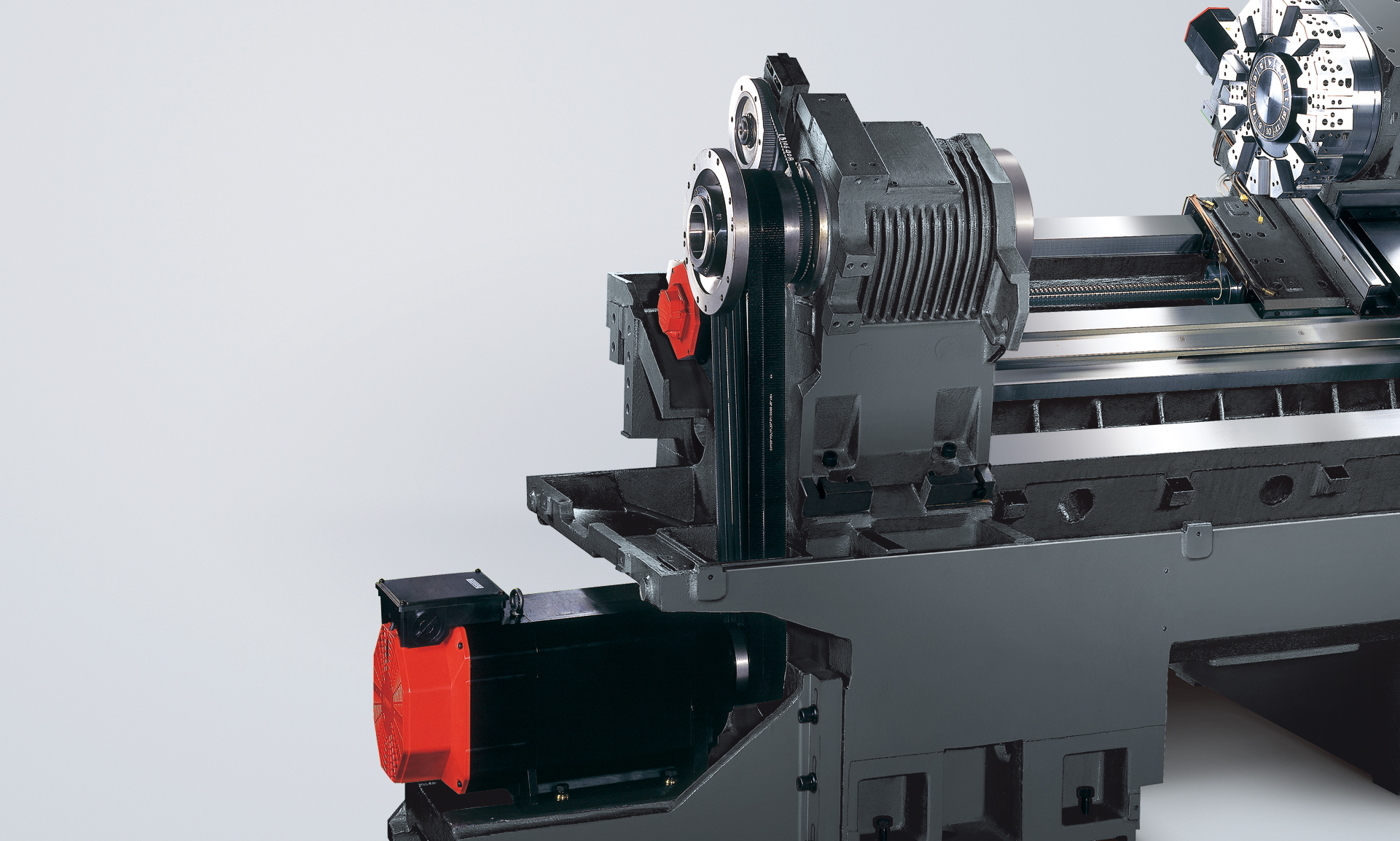

Packed with industry leading technology and top quality components, the GOODWAY GS-200 series turning centers combine incredible power, strength, and speed to bring you The Ultimate Machining Power®. These powerful ultra performance machines will easily accomplish the demanding turning applications of today and tomorrow. 2 bed lengths ( utilizing the same advanced design ) and 3 spindle sizes offer a total of 6 basic model configurations to suit your application. Furthermore, with available live tooling, C-axis, Y-axis, and sub-spindle capabilities, milling, drilling, and front / backend turning applications may be completed in one single machine.

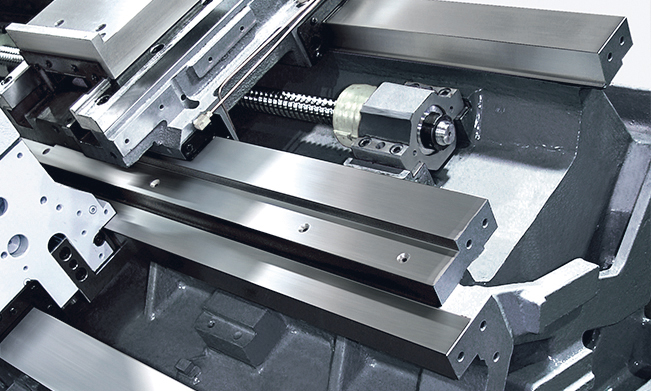

- High rigidity box way slant bed.

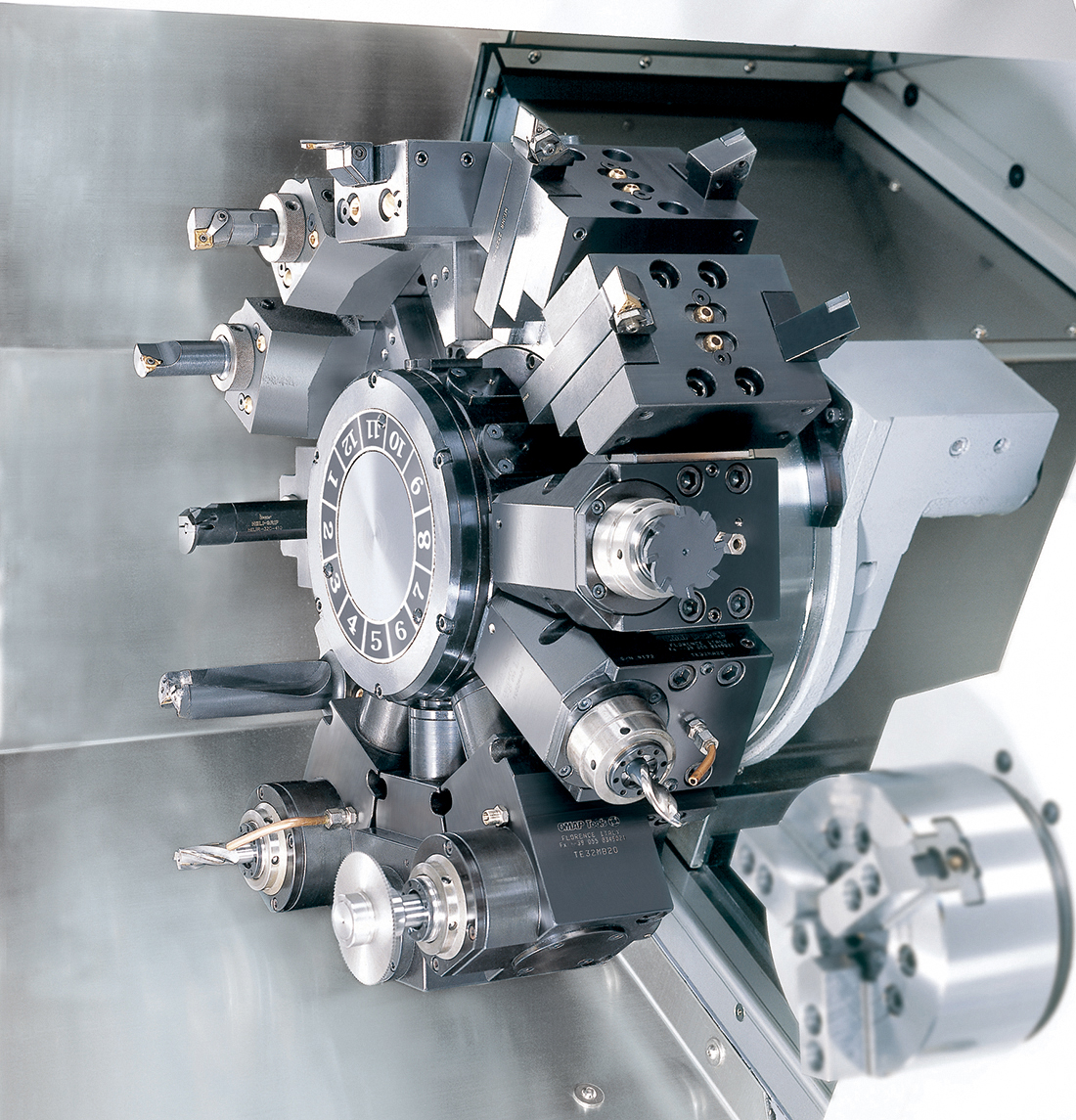

- Comprehensive turning and milling capabilities with a live tooling turret, Y-axis, and sub-spindle.

- The box way design also provides the rigidity needed for heavy duty and interrupted turning applications.

- The low-gravity 30° slant bed design provides an exceptionally stable base for the turret and spindle.

- Equipped with an αP series wide-range spindle motor, full horsepower output is achieved at 1/2 the RPM of standard motors.

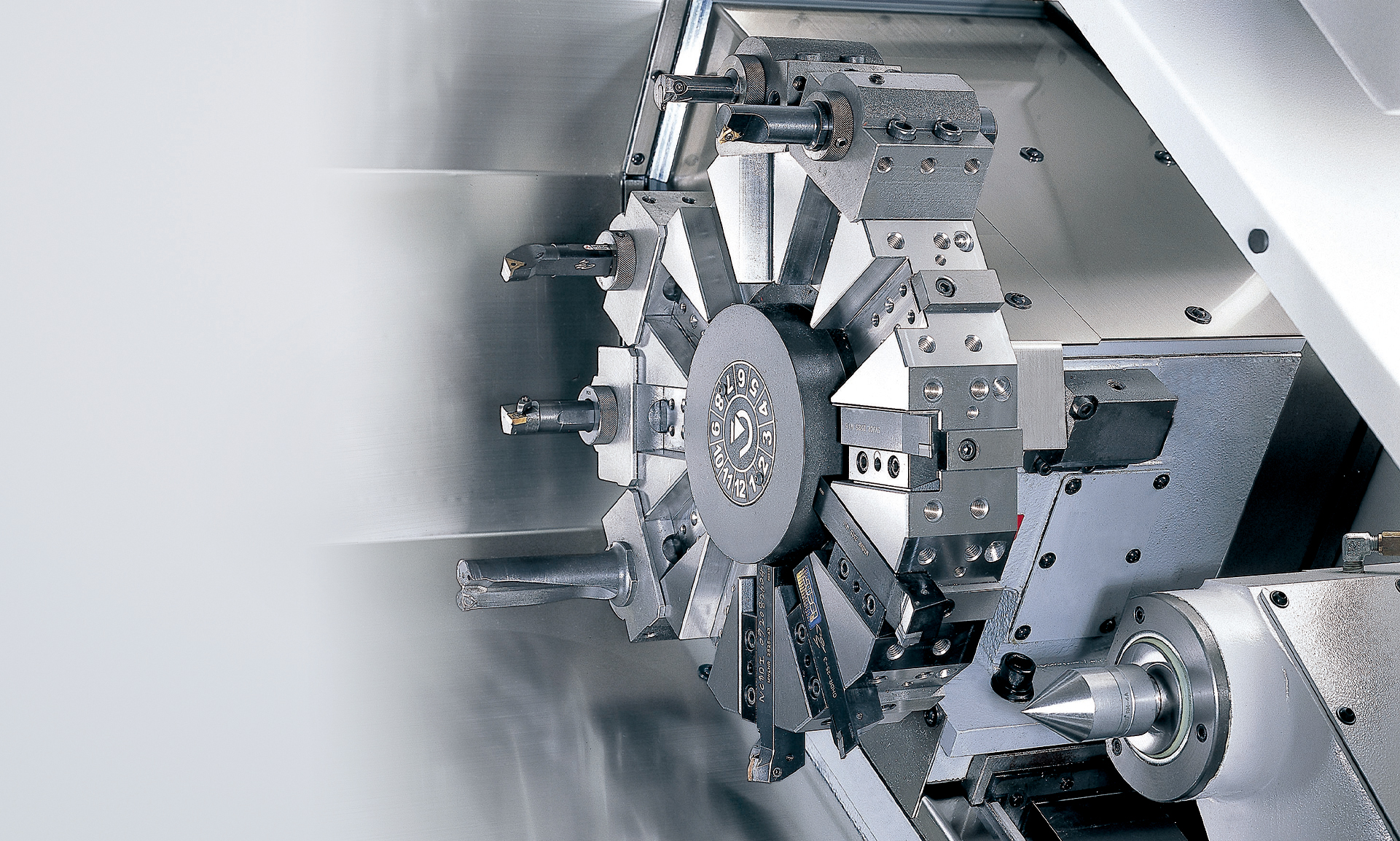

- Heavy-duty 12-station servo indexing turret design; opposing tool change takes only 0.5 seconds.

- High-efficiency programmable tailstock.

- Self-centering steady rest.

- With a live tooling spindle speed of 4,000 rpm, it can easily handle various machining tasks such as milling, drilling, and tapping.

- The sub-spindle features a 6-inch chuck and is driven by a 7.5 kW built-in motor, reaching a maximum speed of 6,000 rpm.

- The Y-axis control, with a ±55 mm stroke, provides the capability to machine complex workpieces.

Features

High Rigidity Structure

The Ultimate Machining Power

User-friendly Operation

Integrated Machining

Model Variations

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

Live Tooling Turret

- The 12-station GOODWAY live tooling turret offers 12 stations available for live tooling ( live tooling tools rotate in working position only ) and features a non-lifting turret disk.

- GOODWAY's live tooling turret utilizes advance servo indexing technology to achieve 0.2 second indexing times for adjacent stations and 0.5 second for stations at the opposite end of the disk.

- With the latest technology, live tooling is driven by an AC servo motor to provide ample power, in the form of torque. Now, even the toughest of jobs may be tackled without a sweat.

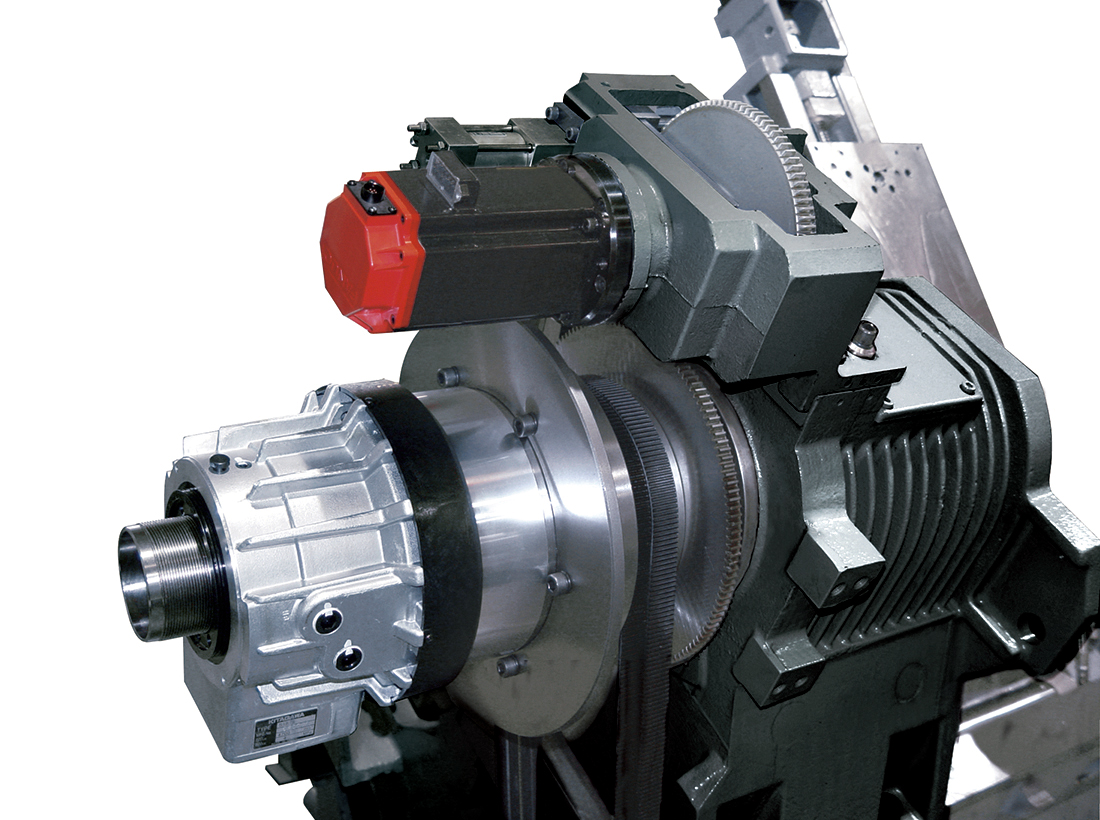

C-axis

- The Cf-axis and disk brake system provide the most rigid and powerful type of C-axis control on the market today.

- Working with the live tooling turret, the Cf-axis and disk brake system enables the machine to perform multiple tasks, such as drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations.

- With the FANUC servo motor generating an ultra high resolution of 120 million pulses per spindle rotation and 240 Nm ( 176 ft-lb ) of torque ( cont. ), machined surface finishes are much superior than Cs-axis ( driven by spindle motor ) equipped machines. Plus, dynamic accuracy is within ± 0.02° even under heavy cutting loads.

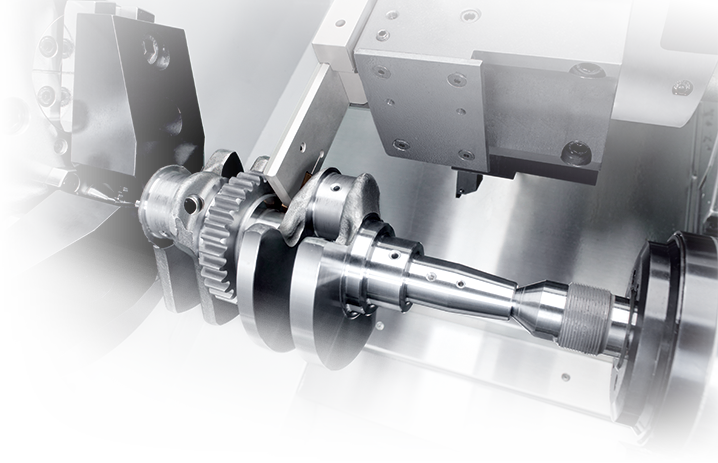

Back Processing Capacity

- A 6" chuck size sub-spindle driven by a powerful 7.5 kW ( 10 HP, 30 min. ) built-in type FANUC motor ( Integrated Motor ) for back-end machining is available on the GS-200 series.

- The sub-spindle travels on the B-axis, which has extra wide hardened and ground box ways. The box ways are directly formed onto the machine bed during the casting process. They are precision machined and widely spaced for maximum strength.

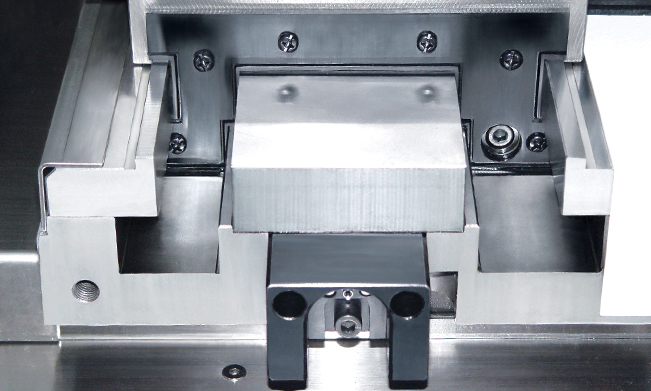

Y-axis Control Function

- Y-axis control further enhances multi-tasking live tooling capabilities and improves various machining precision. High precision grooving and X-axis off-center drilling are enabled.

- With an abundant amount of Y-axis travel, 110 mm= ± 55 mm ( 4.33" = ± 2.16" ), a wide variety of parts may be efficiently machined.