GLS-2800 / GLS-3300

With the latest machine tools technology and high quality components, GOODWAY brings you the new GLS-2800 / GLS-3300 series high speed CNC turning center. This series is based on high precise linear guide ways and featured big bore, high power, fast cut and more to provide you machining solution with high efficiency cutting power. Besides, the GLS-2800 / GLS-3300 series equipped with an optional live tooling turret, C-axis, Y-axis, sub-spindle and various automation equipment to reach a complete series and easily meet your machining needs of today and tomorrow.

- High-performance slant bed with linear guide ways; bar capacity Ø75 mm / Ø90 mm.

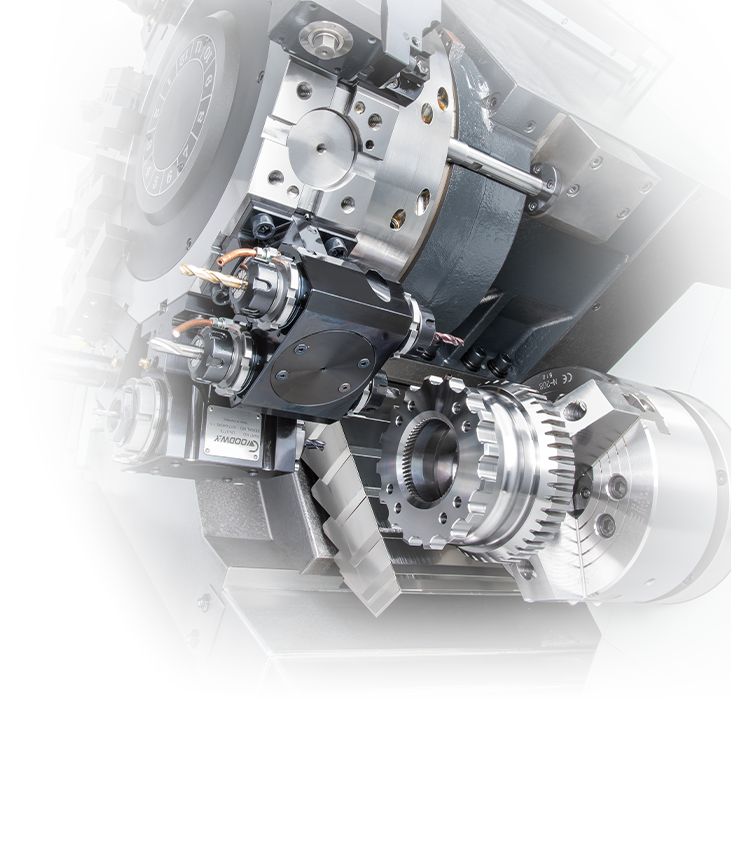

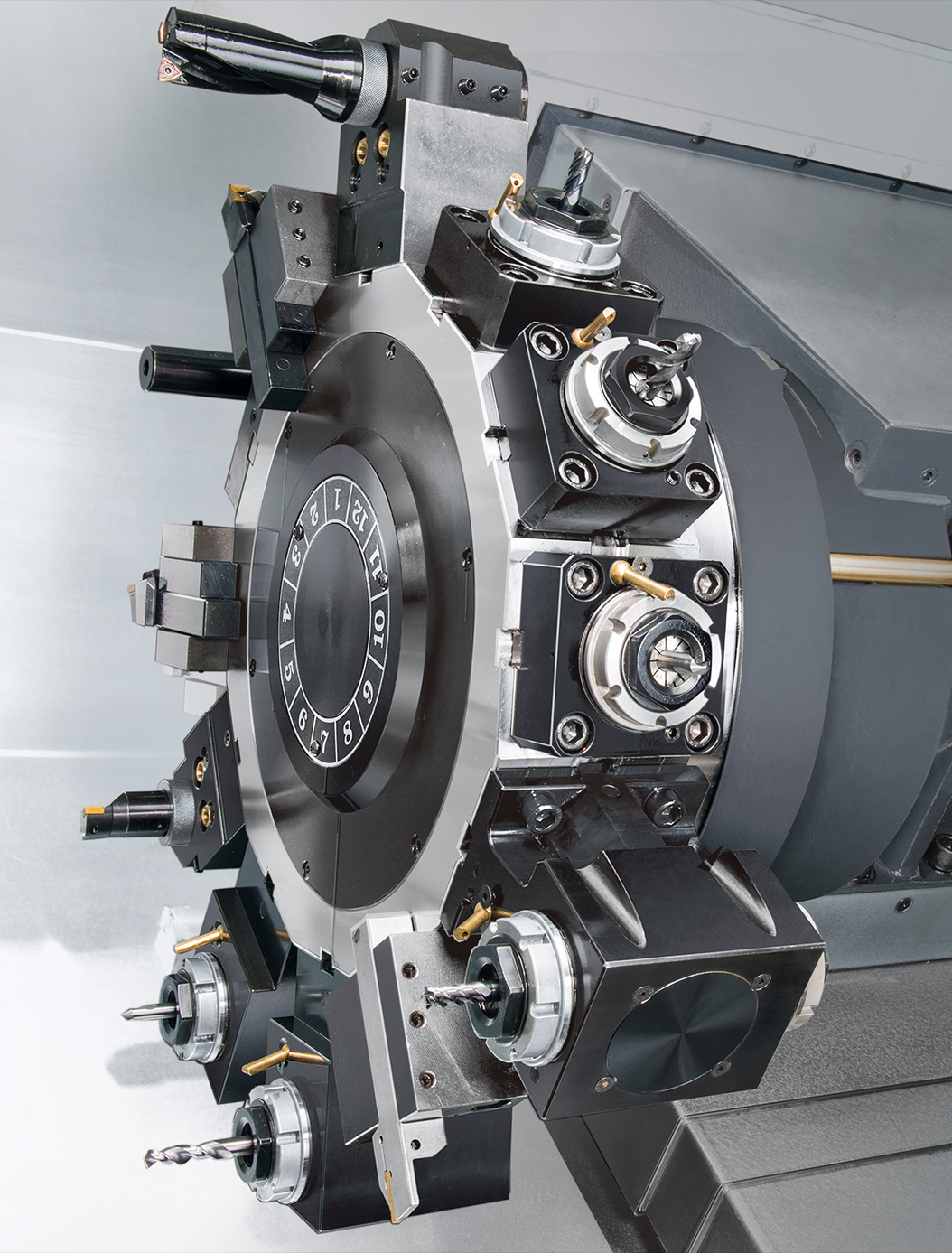

- Comprehensive turning and milling capabilities with a live tooling turret, Y-axis, and sub-spindle.

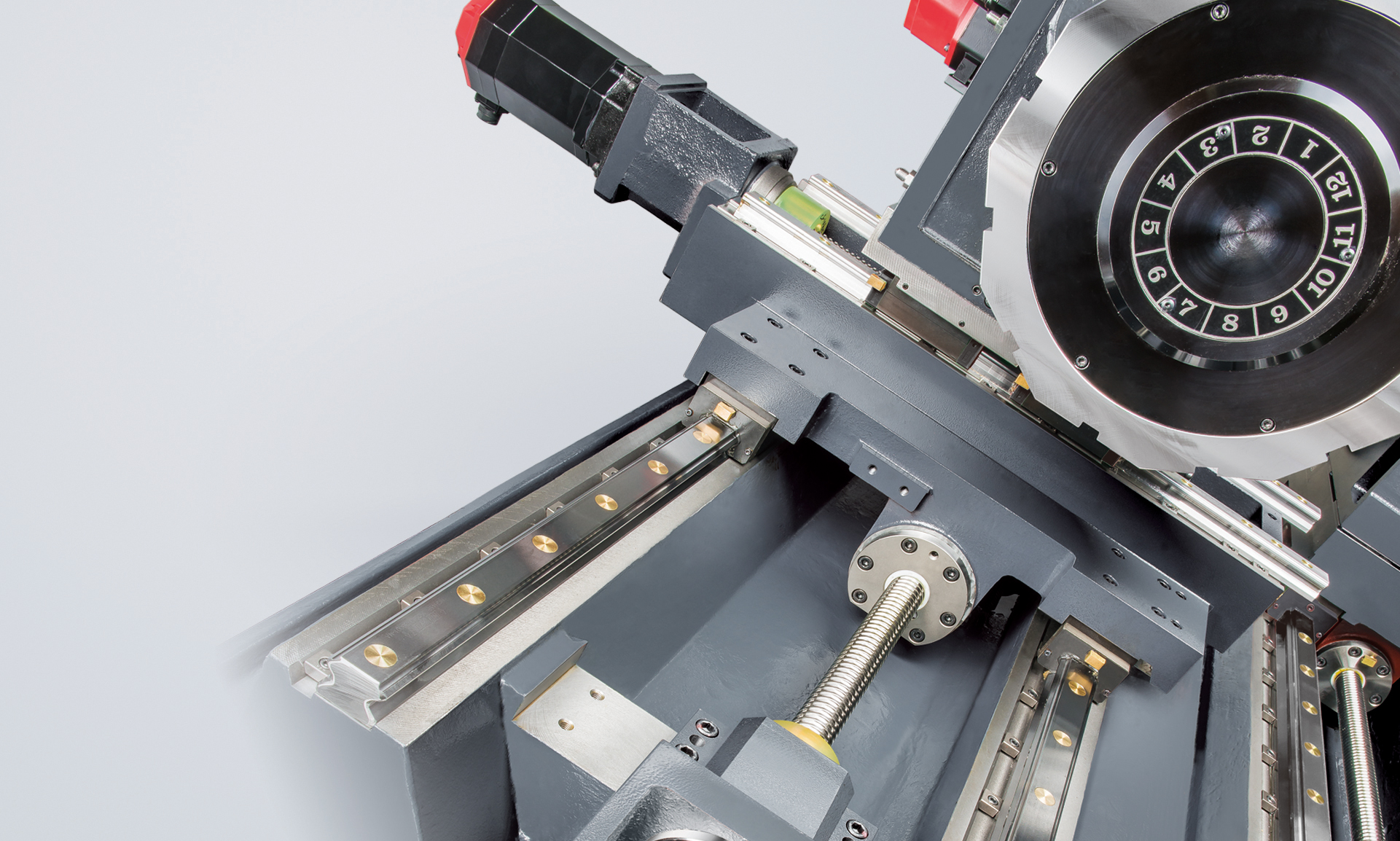

- High precision linear guide way design is used in X and Z axes to provide the optimum control and efficient movement.

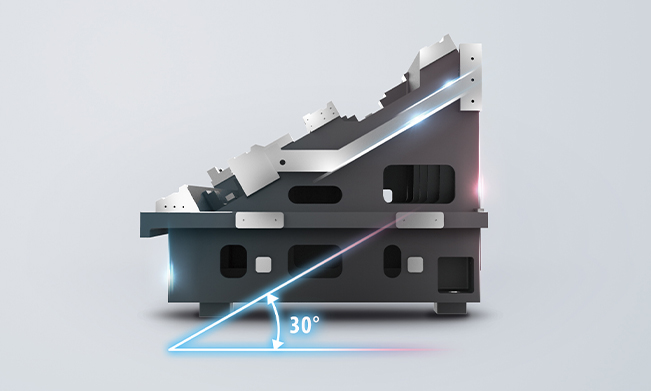

- The low center of gravity 30° slant bed design ensures maximum structural rigidity.

- The 18.5 kW high-power spindle motor delivers robust heavy cutting capability (GLS-2800: 15 kW).

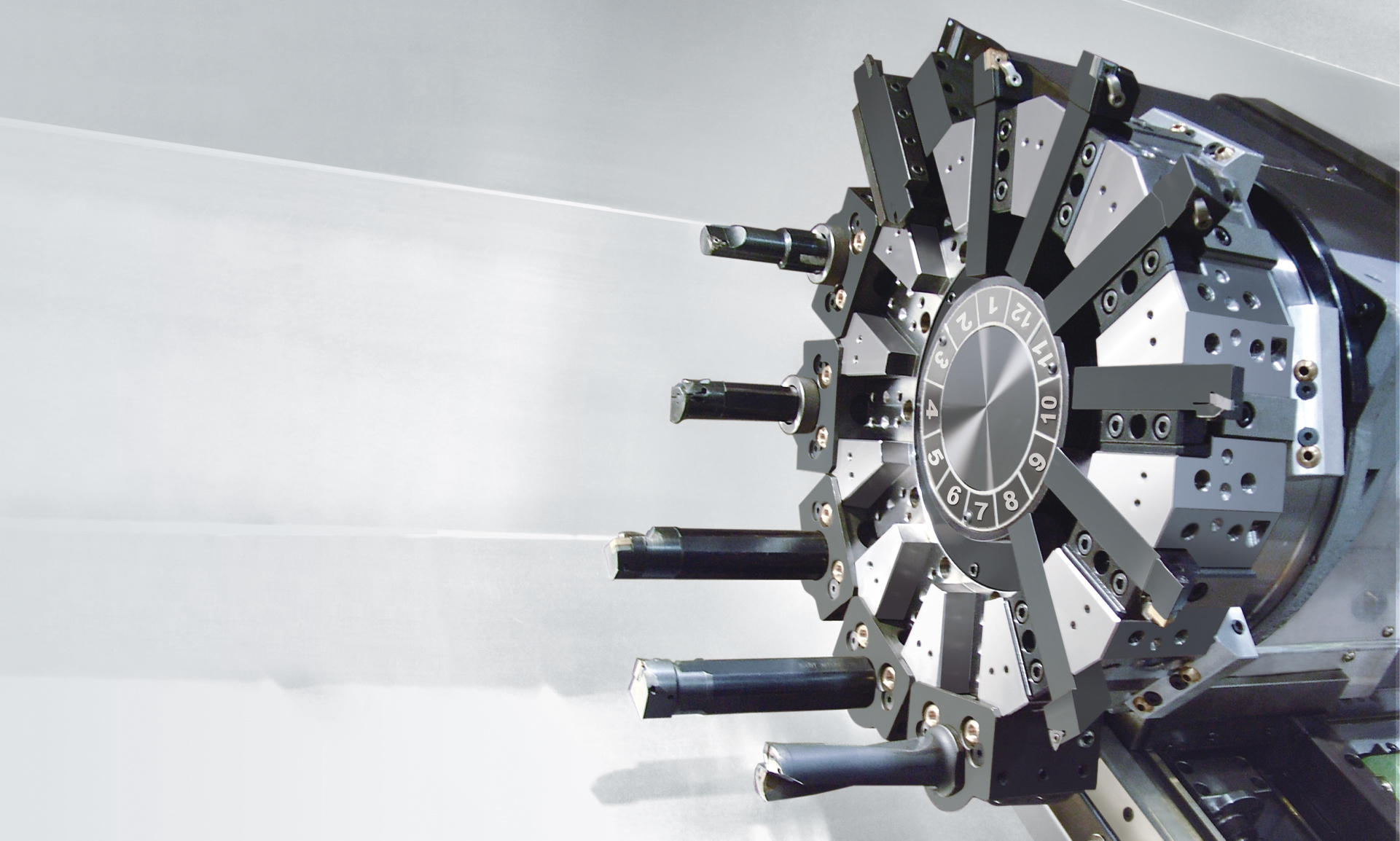

- The 12-station servo turret enables rapid tool changes and delivers outstanding cutting rigidity for high-performance cutting.

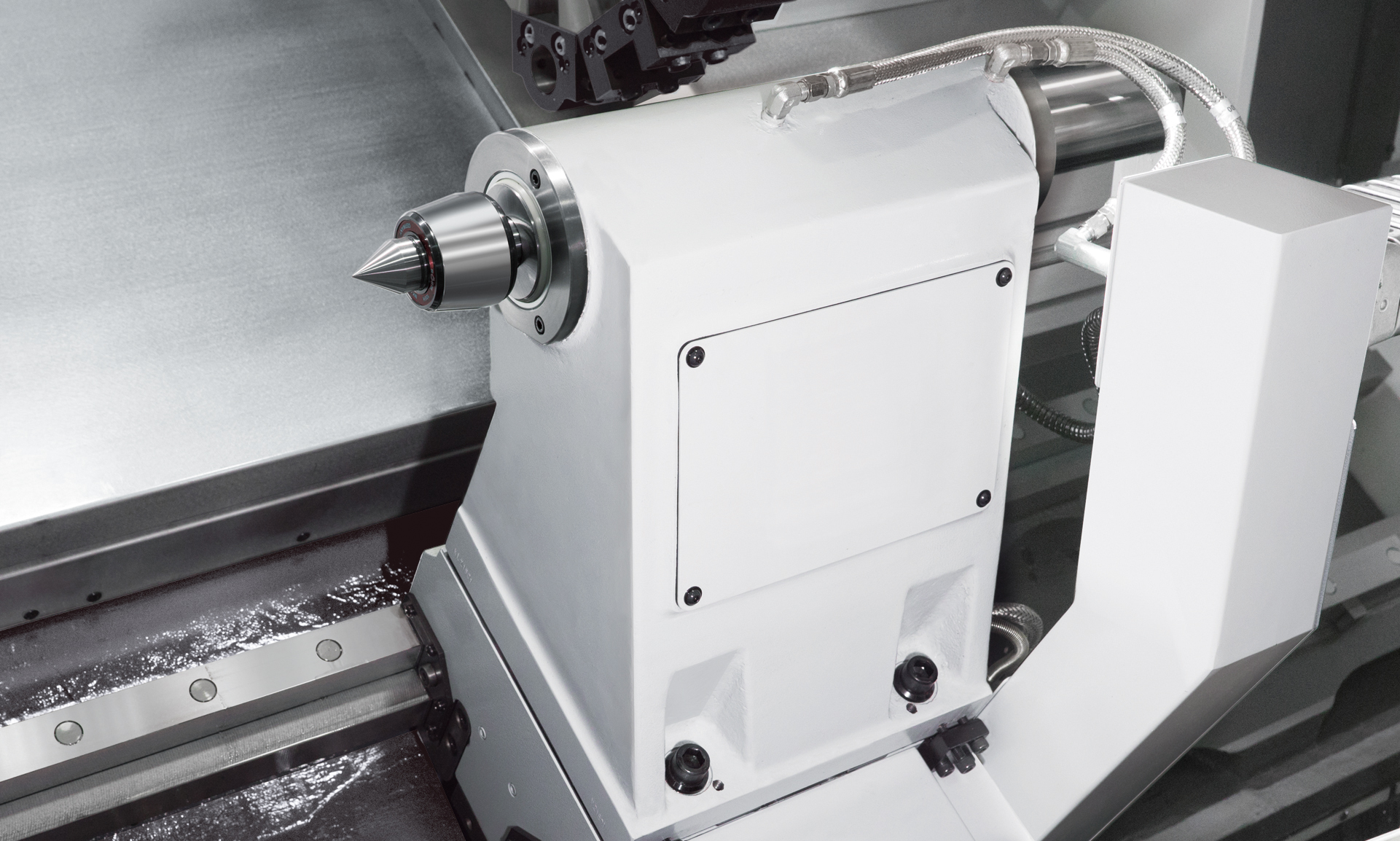

- High-efficiency programmable tailstock with MT#4 live center.

- Optional 12 or 16-station live tooling turret with live tool speed up to 6,000 rpm.

- Sub spindle equipped with 8" chuck and driven by an 11 kW spindle motor, delivering a maximum torque of 105 Nm.

- Y-axis control with ±50 mm travel enables machining of complex workpieces.

Features

High Rigidity Structure

The Ultimate Machining Power

User-friendly Operation

Integrated Machining

Model Variations

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

Live Tooling Turret

- The high-rigidity three-piece curvic coupling design features a non-lifting turret disk and features a non-lifting turret disk.

- The 12-station GOODWAY live tooling turret offers 12 stations available for live tooling ( live tooling tools rotate in working position only ).

- With the latest technology, live tooling is driven by an AC servo motor to provide ample power, in the form of torque. Now, even the toughest of jobs may be tackled without a sweat.

C-axis

- The C-axis features an ultra-high rigidity Cf-axis combined with a disc brake system, driven by a high-torque FANUC servo motor with 240 Nm (cont.) output. It ensures excellent surface machining accuracy and maintains dynamic precision within ±0.02°, even under heavy cutting conditions.

Back Processing Capacity

- All series could select the optional sub-spindle to machine the back-end after receiving the part. Ø 51 mm bar capacity adopts 8" chuck featuring ejector, which allow the finished parts can smoothly drop on parts catcher successfully. All the processes from loading the parts can all be done in one machine without a pause.

Y-axis Control Function

- The optional Y-axis control can achieve X, Y, Z, C axes simultaneously machining, which allow the series can work on Y-axis 100 mm off-center milling ( off-center ± 50 mm ), drilling, and tapping as well as improving the machining accuracy from a regular 3 axes simultaneously machining processes.