GLA-1500

In today’s fast-paced and ever-changing world, manufacturers are increasingly challenged by tighter delivery schedules and shrinking profit margins. The need for cost-effective machining solutions to boost production efficiency has never been more urgent. The GOODWAY GLA-1500 Series is a groundbreaking product designed to meet these demands. Specifically developed for small-part machining, this series features a compact footprint and outstanding machining capabilities. Whether used as a standalone unit or integrated into a fully automated production line, it delivers the performance you need to handle any machining requirement.

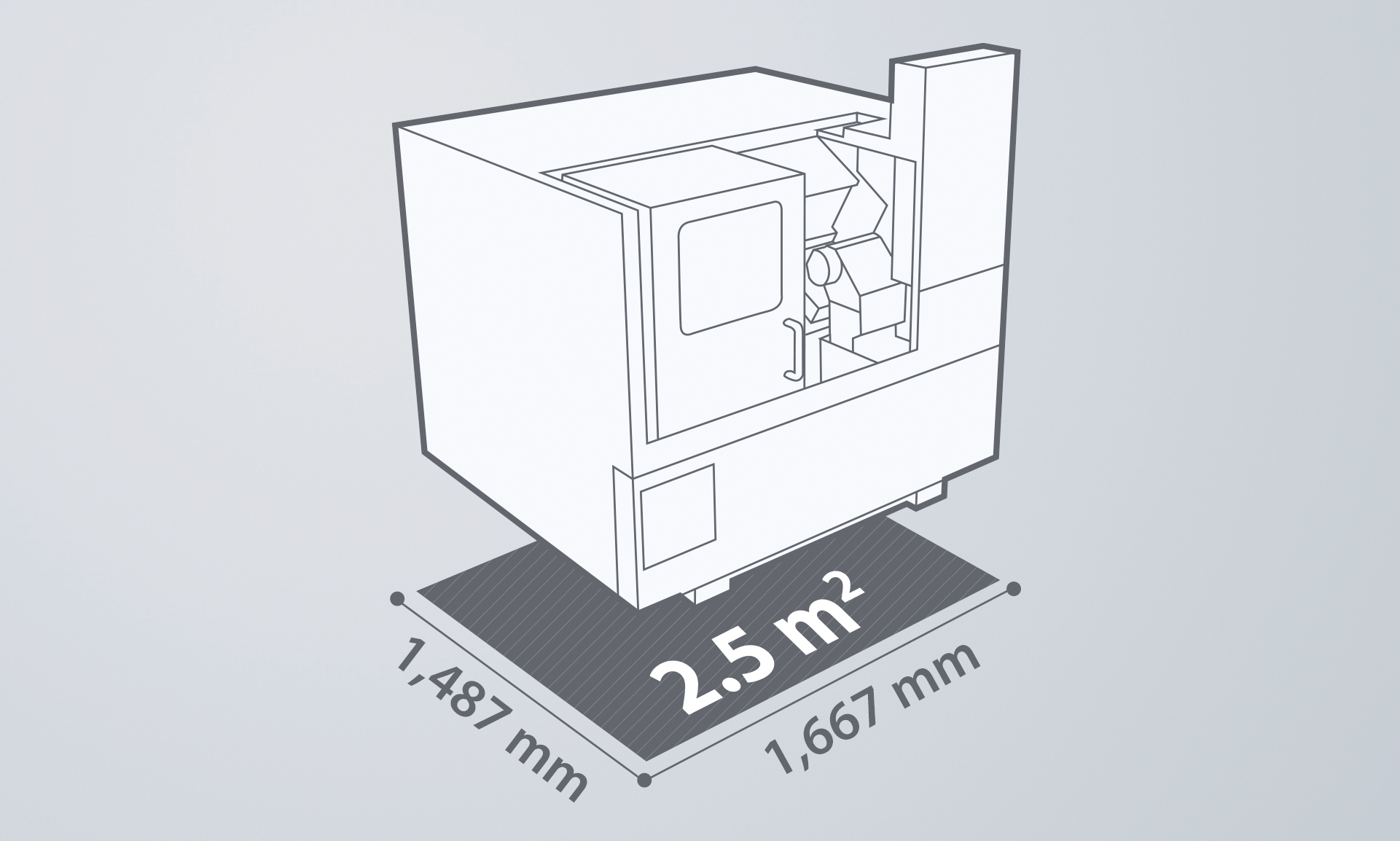

- Extremely compact 2.5 m2 footprint.

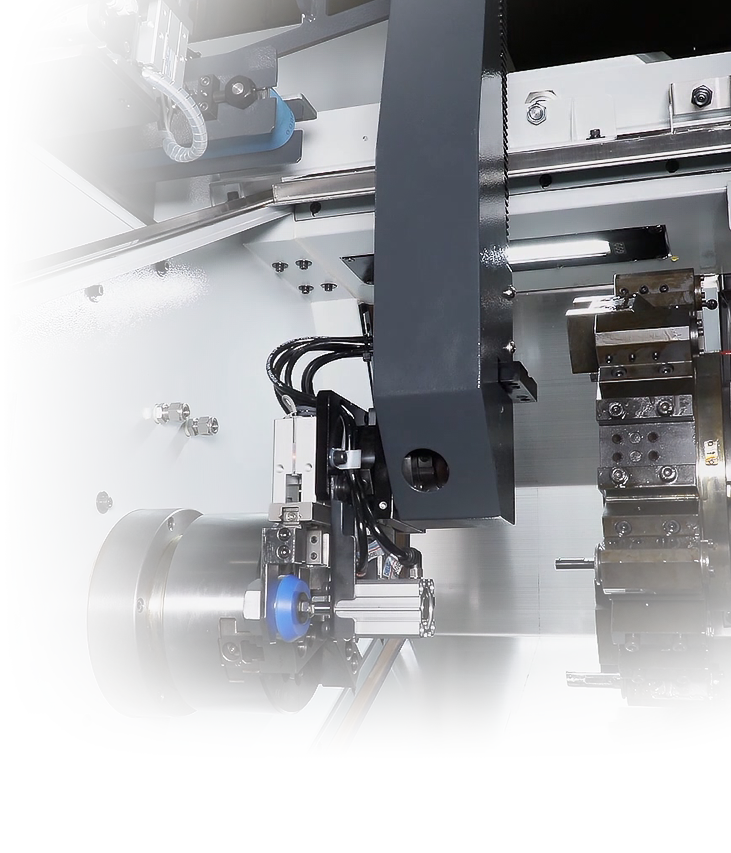

- Equipped with a gantry type loading and unloading system for effortless and efficient mass production.

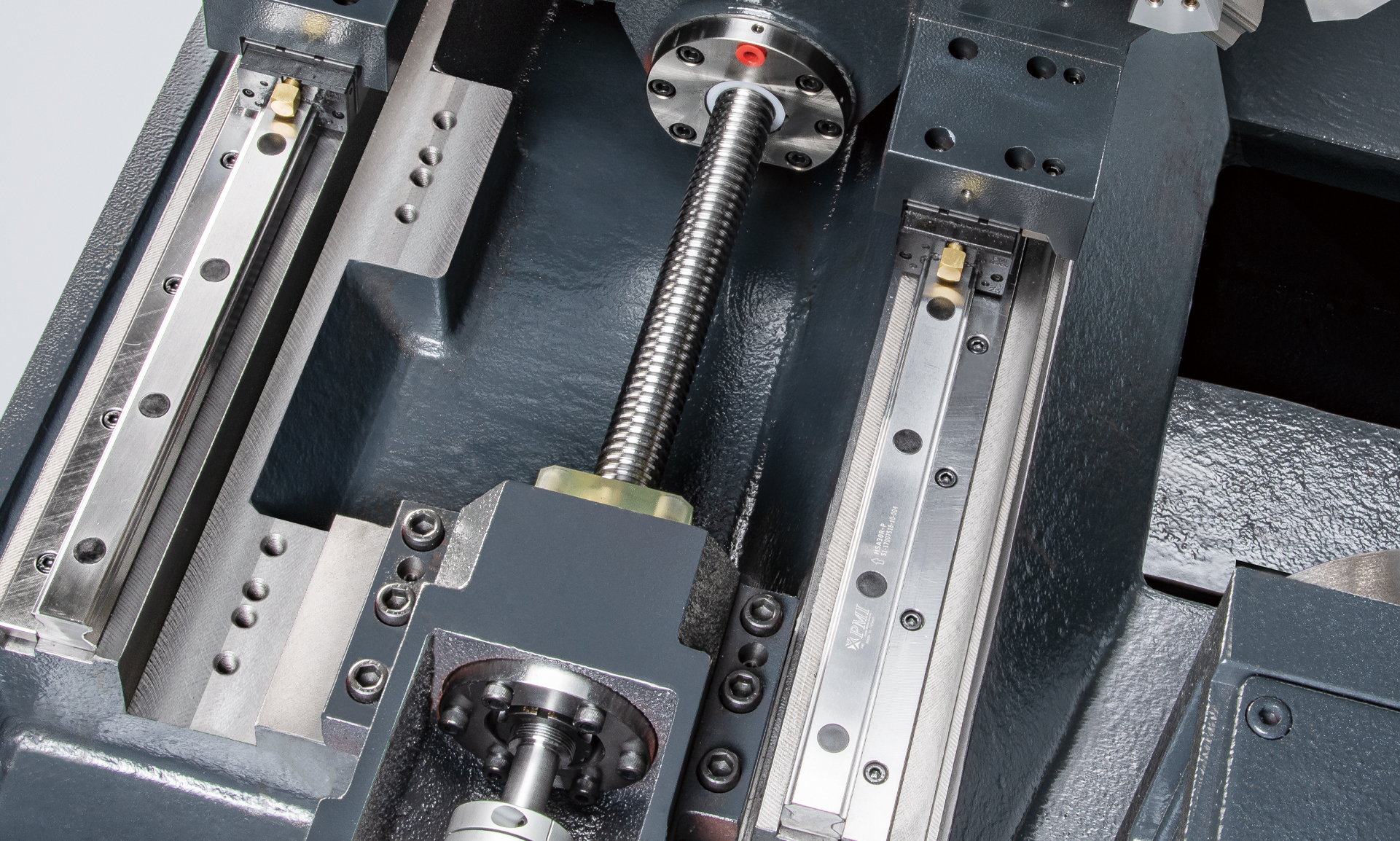

- High precision linear guide way design is used in X and Z axes to provide the optimum control and efficient movement.

- C3 class hardened and precision ground ball screws ensure the highest accuracy and durability possible.

- High-reliability spindle system design with a maximum speed of 4,500 rpm (optional 6,000 rpm).

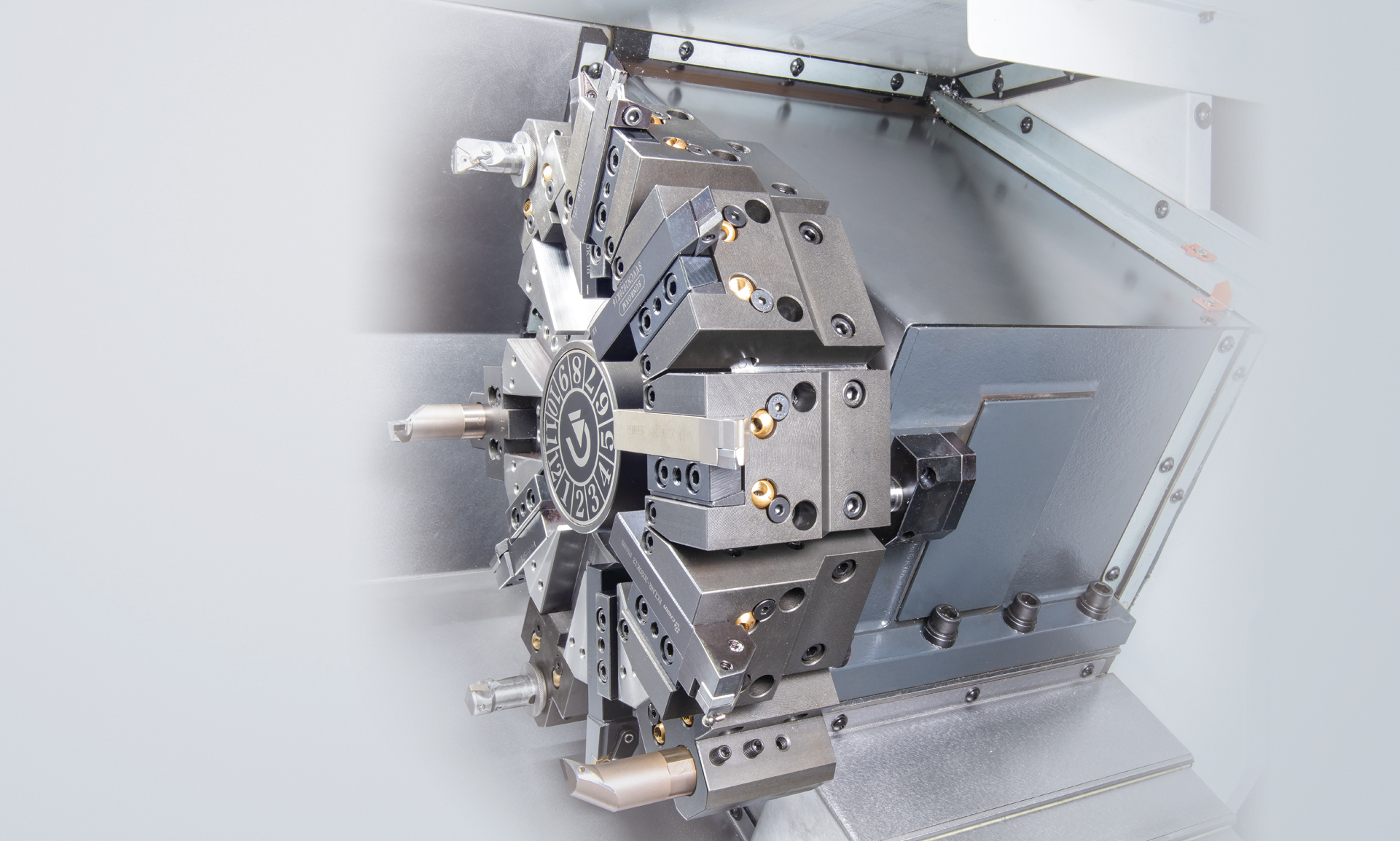

- High-efficiency 12-station servo indexing turret design; opposing tool change takes only 0.5 seconds.

- The fixed tailstock offers exceptional rigidity and the quill movement is programmable.

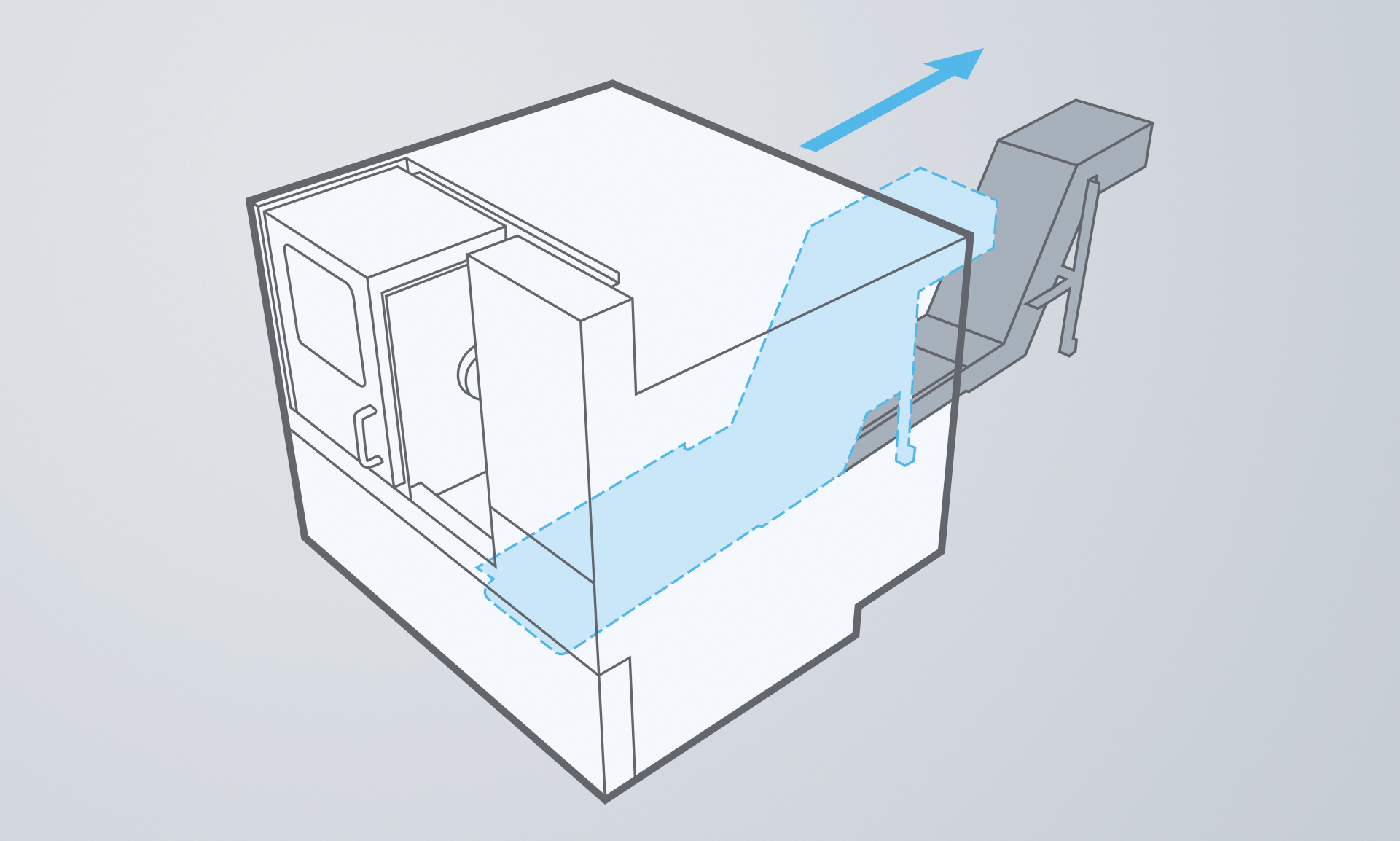

- Rear-discharge chip conveyor allows for a more compact machine layout on the production line.

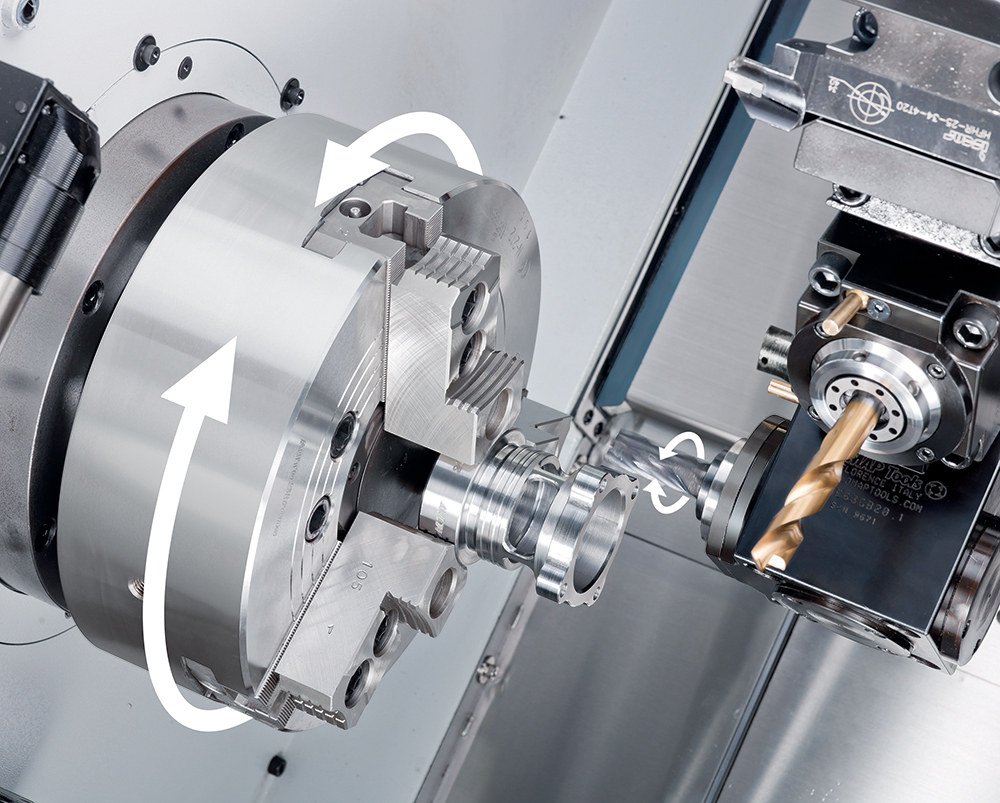

- Optional 12-station live tooling turret is available, with a maximum live tooling speed of up to 4,000 rpm.

- The live tooling turret, combined with GOODWAY live tool holders, delivers exceptional milling performance.

Features

High Rigidity Structure

The Ultimate Machining Power

User-friendly Operation

Integrated Machining

Model Variations

- Live tooling turret

- C-axis

Live Tooling Turret

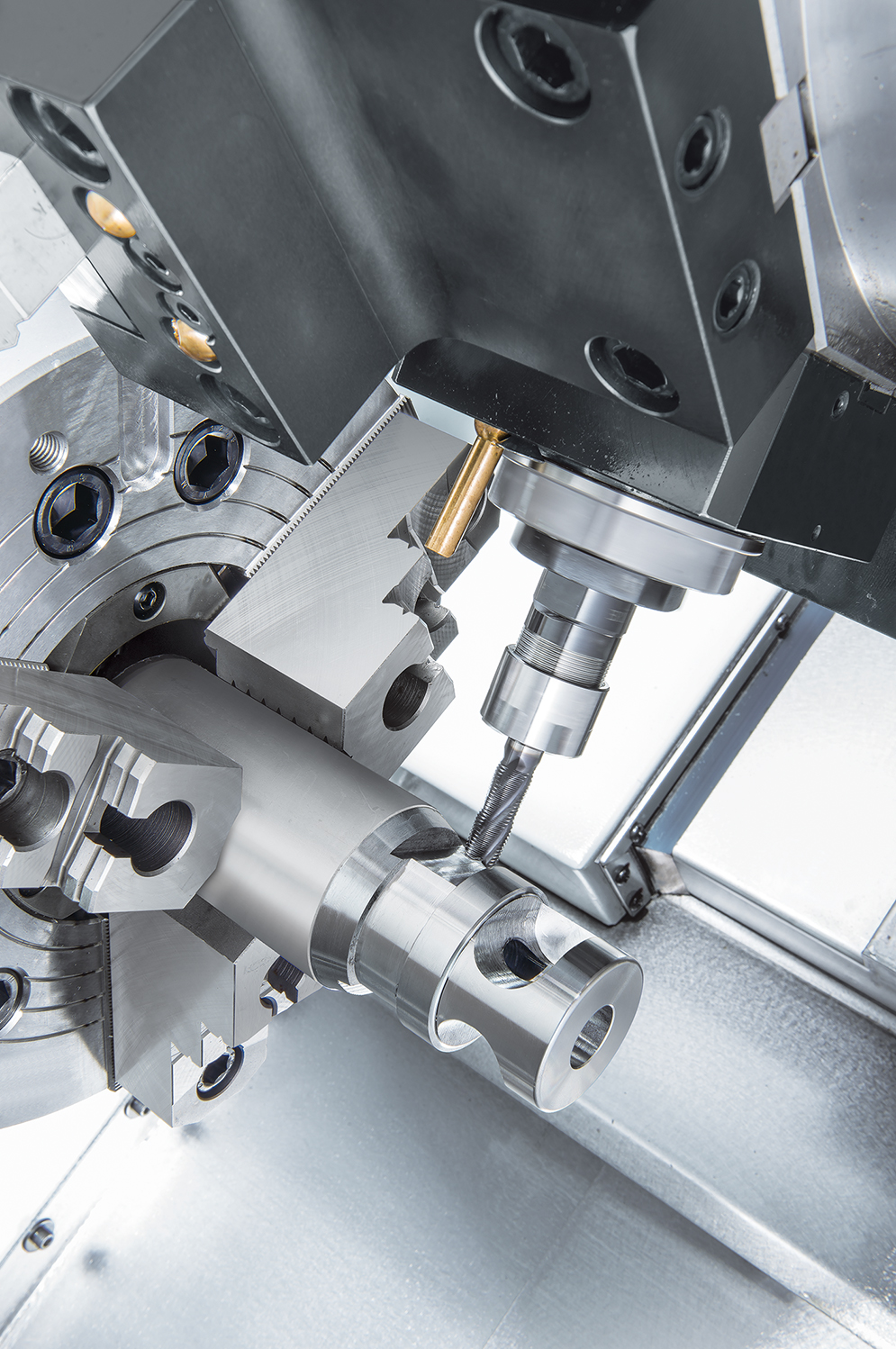

- Live tooling and C-axis control capabilities on the GLA series allow the machine to perform multiple tasks on a work-piece, such as turning, milling, drilling and tapping. This eliminates manpower and cycle time, while reducing accuracy lost, which will occur if the part is moved from one machine to another.

- GOODWAY 12 stations turret equip 6 live tools which are driven by AC servo motor which can provide ample power, in the form of torque. Now, even the toughest of jobs may be tackled without a sweat.

C-axis

- Spindle can switch to C-axis servo mode control by Cs-axis design, providing rapid and accurate indexing and satisfying high-efficiency production output.