HA

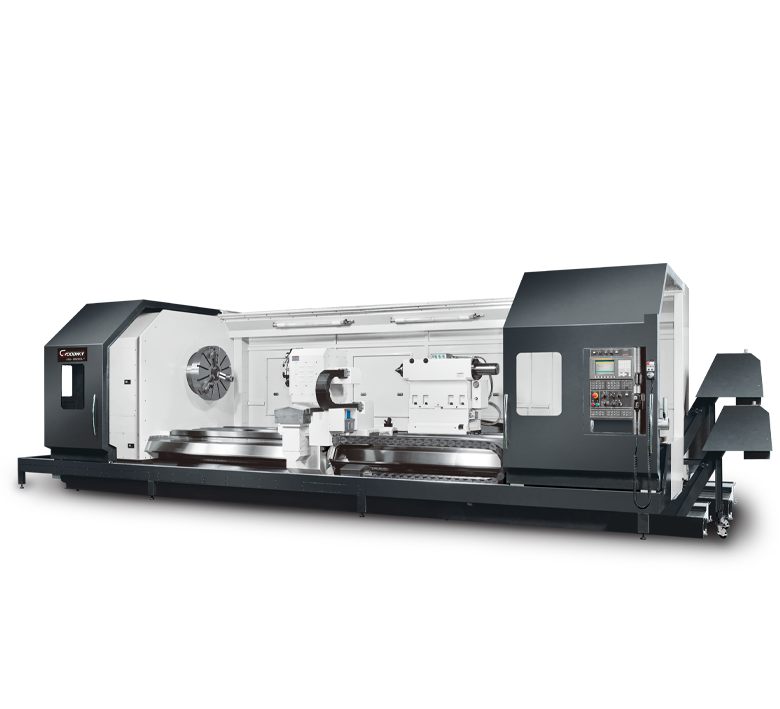

Together with the latest technology and high quality components, the GOODWAY HA series utilizes high rigidity four box way bed with 3-step gear spindle and servo indexing turret to provide heavy-duty cutting capability for super large work-piece applications. It is suitable for energy, aerospace and shipbuilding industry.

The optional four-way toolpost, boring bar, and steady rest provide a more efficient turning performance for large work-piece applications. Furthermore, the live tooling turret and C-axis is also available which allows the machine to perform more complicated tasks such as turning, milling, and drilling to fulfill your needs for today and tomorrow.

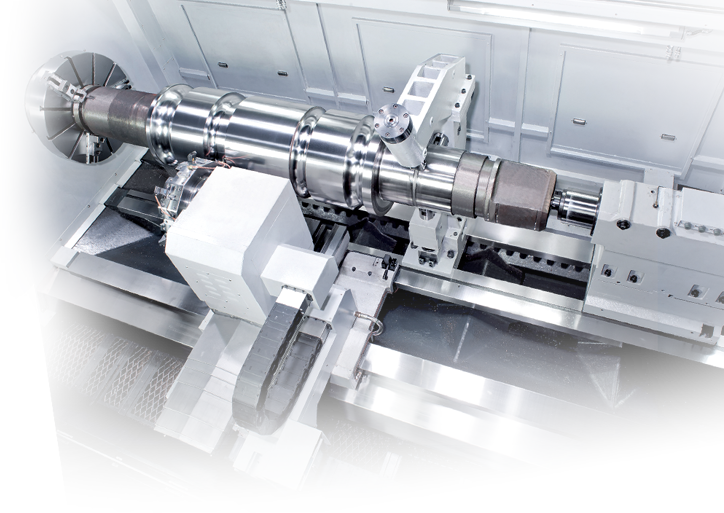

- The optimal production solution for extra-long, large-diameter workpieces.

- Maximum turning diameter Ø1,700 mm, maximum turning length 10,000 mm.

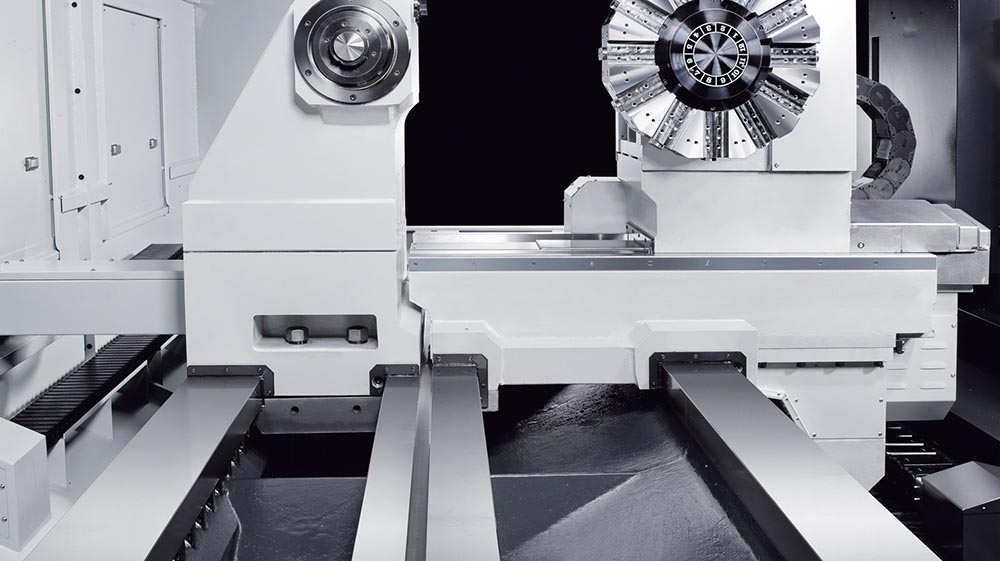

- One-piece, wide-span four-way cast iron base with high rigidity and excellent vibration damping capabilities.

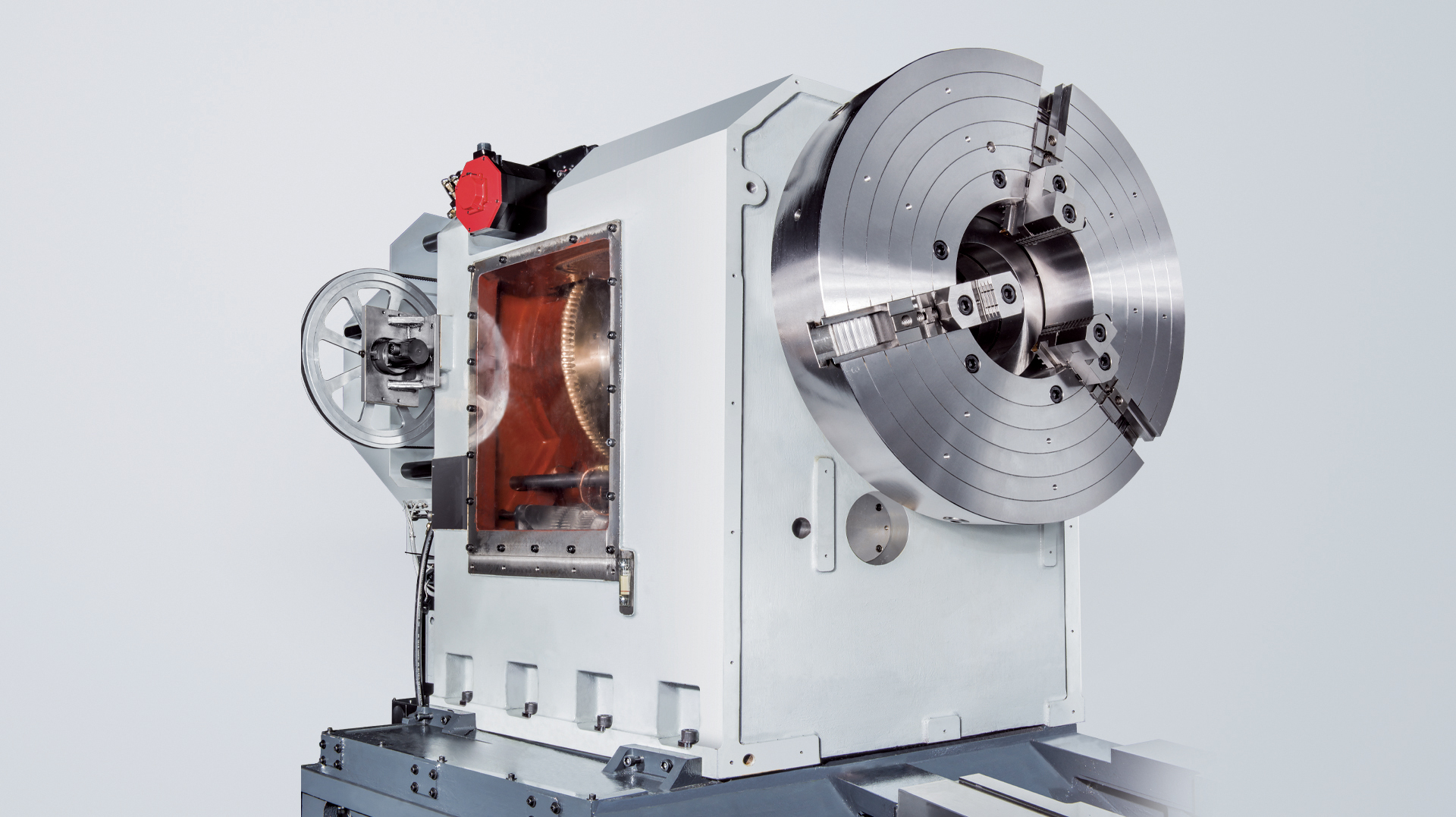

- The super-heavy duty spindle headstock is a one-piece casting, weighing a total of 4,000 kg.

- 3-speed geared spindle design with a maximum torque output of 13,300 Nm.

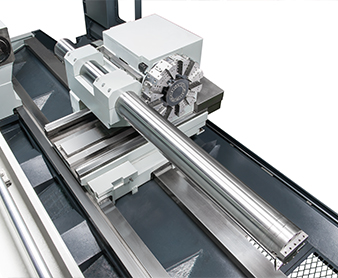

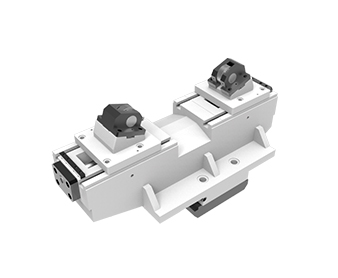

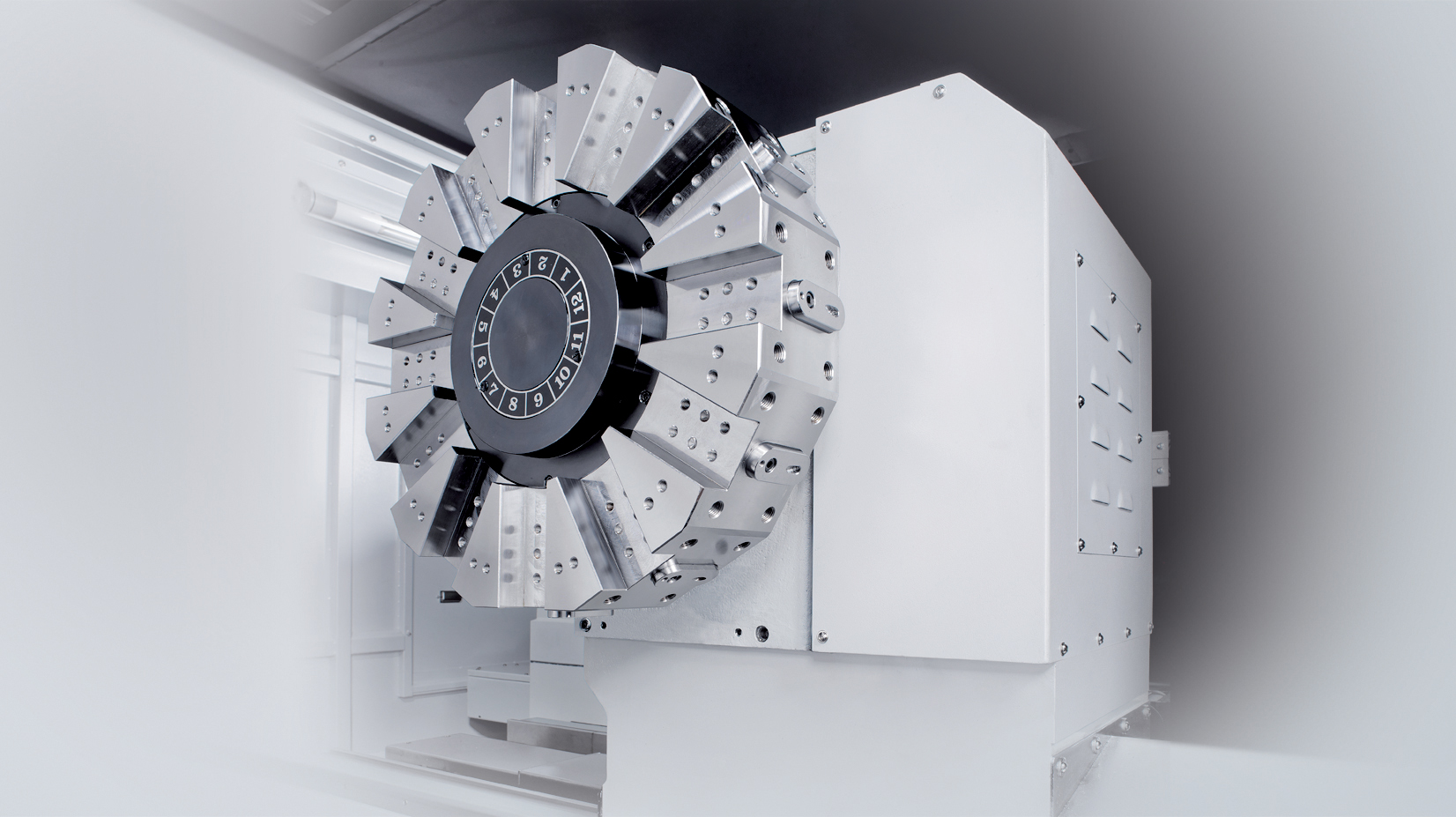

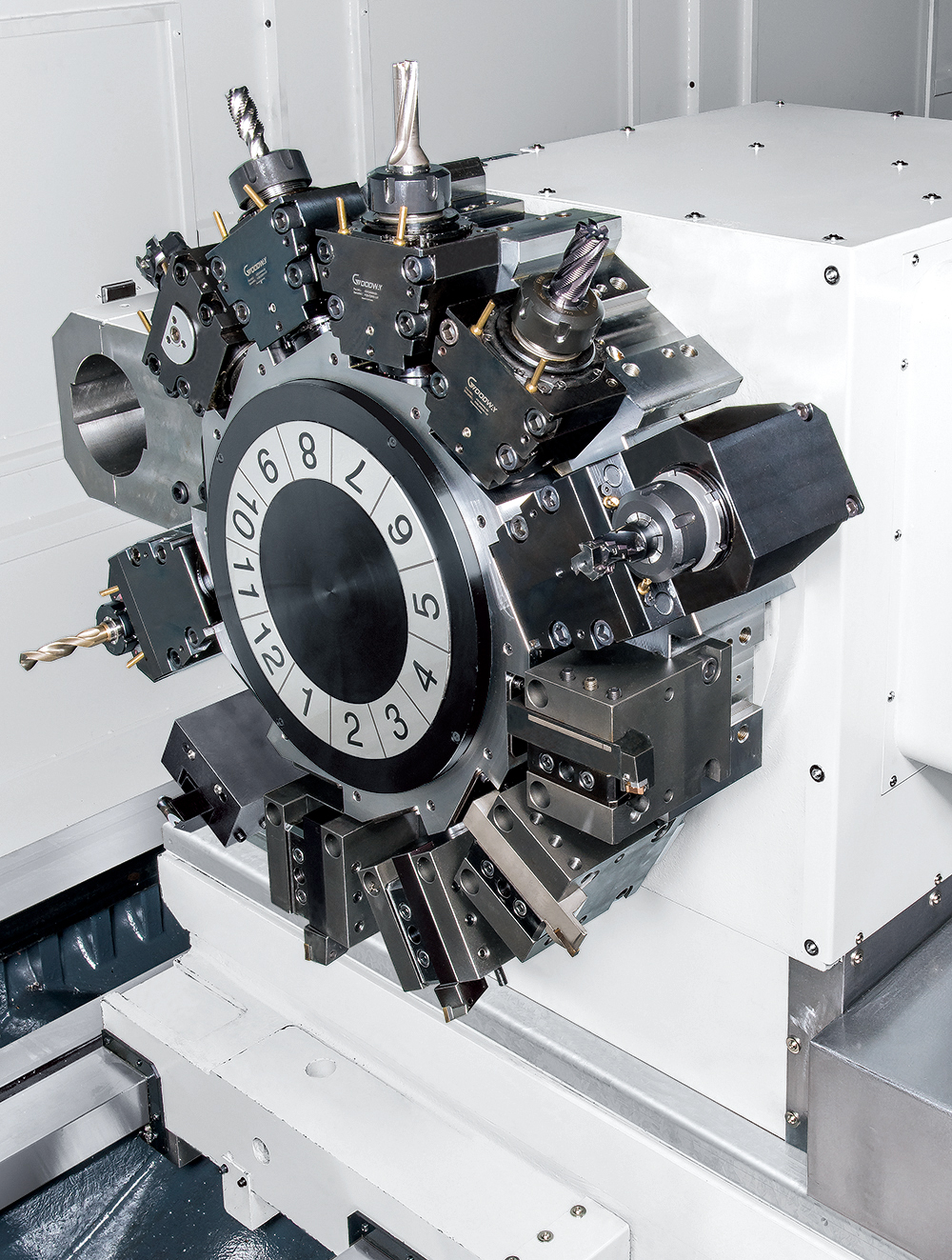

- Optional 12-station turret, four-way toolpost, or large anti-vibration boring bar available upon request.

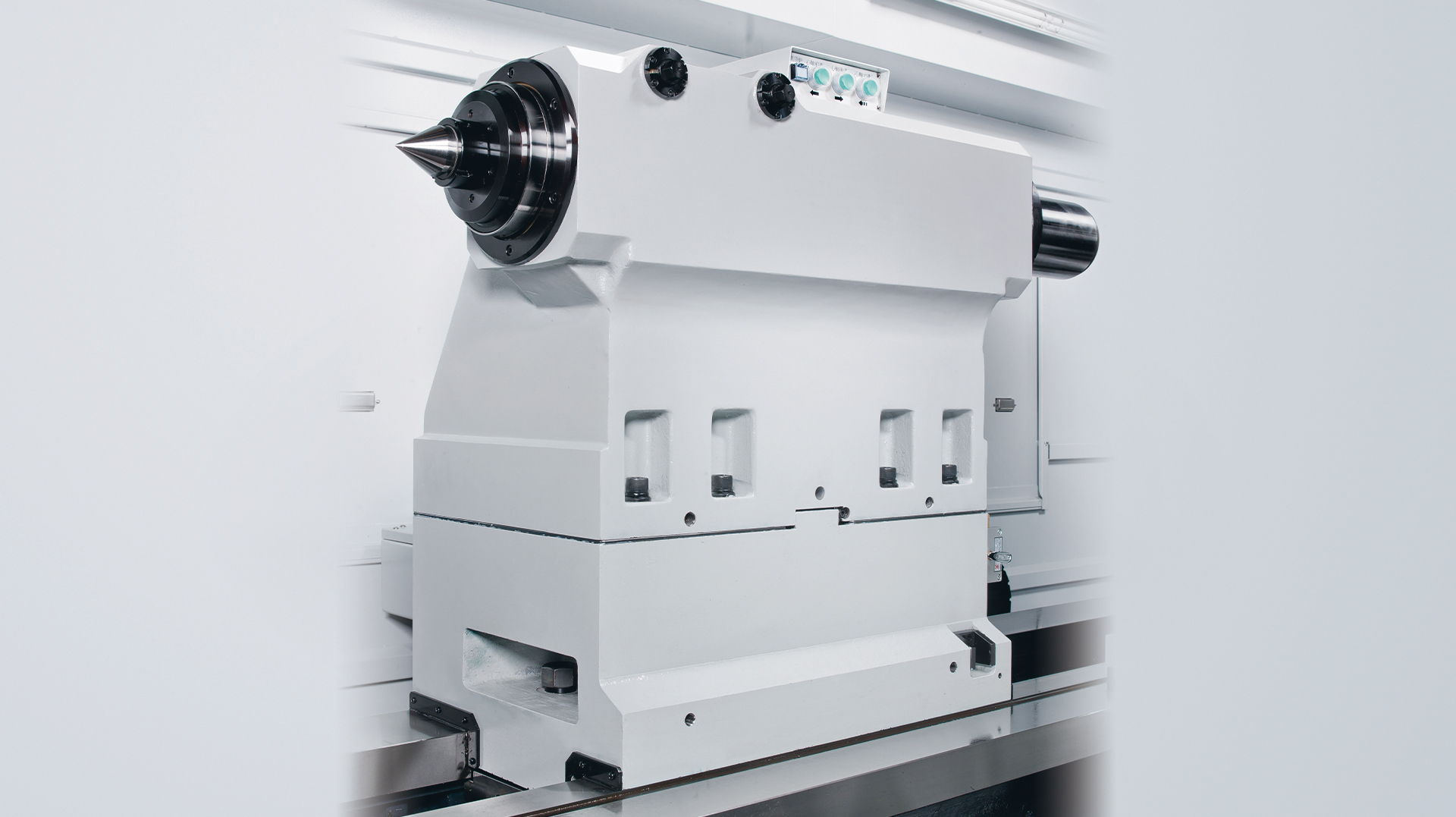

- High-efficiency programmable tailstock with Ø200 / Ø250 mm built-in rotary quill.

- Multiple steady rests are available, allowing for a maximum workpiece outer diameter of Ø1,000 mm.

- Optional 12-station live tooling turret with a maximum live tool speed of 3,000 rpm.

Features

High Rigidity Structure

The Ultimate Machining Power

User-friendly Operation

Integrated Machining

Model Variations

- Live tooling turret

- C-axis

Live Tooling Turret

- Live tooling and C-axis control capabilities on the HA series allows the machine to perform multiple tasks on a work-piece, such as turning, milling, drilling and tapping. It eliminates manpower and cycle time, while reducing accuracy lost, which will occur if the part is moved from machine to machine.

- The 12-station GOODWAY live tooling turret offers 12 stations available for live tooling, live tools rotate in working position only to reduce power loss and heat.

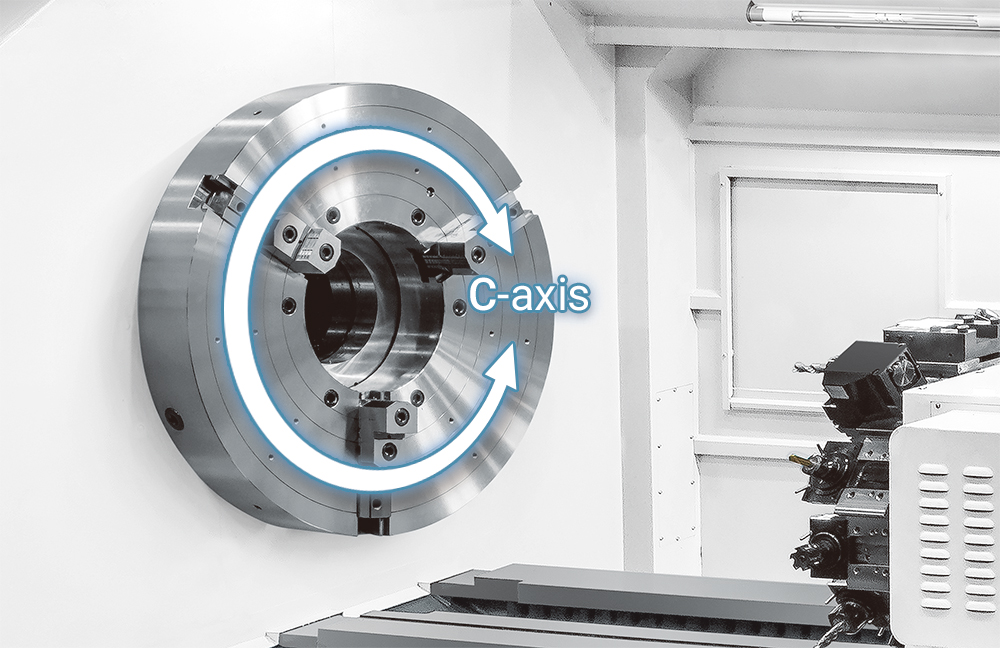

C-axis

- The Cf-axis and disk brake system available on the HA series provide the most rigid and powerful type of C-axis on the market today.

- With the FANUC servo motor generating an ultra high resolution of 1,000,000 pulses per spindle rotation and 1,500 Nm of spindle torque ( cont. ). Plus, dynamic accuracy is within ± 0.02° even under heavy cutting loads.